Schemes of amateur frequency converters. Simple autogeneral voltage converters on transistors Simple converter on domestic transistors

Buy the finished device will not make problems - In auto shops you can find (pulse voltage converters) various power and prices.

However, the price of such an average power device (300-500 W) is several thousand rubles, and the reliability of many Chinese inverters is quite controversial. Making a simple converter with your own hands is not only a way to significantly save, but also the ability to improve your knowledge in electronics. In case of refusal to repair homemade scheme It will be significantly easier.

Simple pulse converter

The diagram of this device is very simpleAnd most parts can be removed from an unnecessary computer power supply. Of course, it also has a tangible drawback - the voltage of 220 volts obtained at the output of the transformer is far from the sinusoidal form and has a frequency much more than the 50 Hz adopted. Directly connect the electric motors or sensitive electronics cannot be directly.

In order to be able to connect to this inverter containing pulse blocks Nutrition equipment (for example, a laptop power supply), an interesting solution was applied - at the output of the transformer installed a rectifier with smoothing capacitors. True, the connected adapter can only work in one position of the socket when the polarity of the output voltage coincides with the direction of the rectifier built into the adapter. Simple consumers like incandescent lamps or soldering iron can be connected directly to the TR1 transformer output.

The basis of the diagram is the PWM controller TL494, most common in such devices. The frequency of the converter is set to resistor R1 and C2 capacitor, their nominations can be taken somewhat different from those indicated without a noticeable change in the operation of the circuit.

For greater efficiency, the converter scheme includes two shoulders on the power field transistors Q1 and Q2. These transistors need to be placed on aluminum radiators if it is intended to use a common radiator - set the transistors through insulating gaskets. Instead of the IRFZ44 or IRFZ48 or IRFZ48 specified on the IRFZ44 scheme, you can use.

The output choke is wound on the ferrite ring from the throttle, also recoverable from computer Block Nutrition. The primary winding is wrapped with a wire with a diameter of 0.6 mm and has 10 turns with a tap from the middle. A secondary winding is wound on top of it containing 80 turns. You can also take the output transformer from a broken source uninterrupted power.

Read the same: Review of electric generators on firewood

Instead of high-frequency diodes D1 and D2, you can take diodes of types FR107, FR207.

Since the scheme is very simple, after switching on with proper installation, it will start working immediately and will not require any configuration. It will be able to give a load to 2.5 A, but the optimal mode of operation will be the current no more than 1.5 A - and this is more than 300 W power.

Ready inverter of such power would cost about three or four thousand rubles.This scheme is performed on domestic components and is old enough, but this does not make it less efficient. Its main advantage is to get a full-fledged alternating current With a voltage of 220 volts and a frequency of 50 Hz.

Here, the oscillation generator is made on the K561TM2 chip, which is a dual D-trigger. She happens to be full analogue Foreign CD4013 chip and can be replaced by it without changes in the scheme.

The converter also has two power shoulders on bipolar transistors KT827A. Their main disadvantage compared to modern fields is greater resistance in the open state, which is why the heating is stronger at the same switching power.

Since the converter operates at low frequency, the transformer must have a powerful steel core. The author of the scheme proposes to use the Common Soviet Network Transformer TS-180.

Like other inverters based on simple Shim-schemes, this converter has a sufficiently different from the sinusoidal output of the voltage at the exit, but it is somewhat smoothed by the large inductance of the transformer winding and the Output capacitor C7. Also because of this, the transformer during operation can produce a tangible hum - this is not a sign of a scheme malfunction.

Simple inverter on transistors

This converter works on the same principle that the scheme listed above, but the rectangular pulse generator (multivibrator) is built on bipolar transistors.

The peculiarity of this scheme is that it retains performance even on a highly discharged battery: the input voltage range is 3.5 ... 18 volts. But, since it does not have any stabilization of the output voltage, when the battery is discharged, it will be simultaneously proportional to fall and voltage on the load.

Since this scheme is also a low-frequency, the transformer will be required to be similar to those used in the inverter based on K561TM2.

Improvements inverter schemes

The devices given in the article are extremely simple and for a number of functions. can not compare with factory analogues. To improve their characteristics, you can resort to simple alterations, which, besides, will better understand the principles of operation of pulsed transducers.

Read the same: Let's make the electric generator with their own hands

Increase output power

All described devices operate according to one principle: through the key element (output shoulder transistor), the primary winding of the transformer is connected to the power input for a time specified by the frequency and the wellness of the specifying generator. At the same time, the magnetic field pulses excited in the secondary winding of the transformer with a voltage voltage in the primary winding, multiplied by the ratio of the number of turns in the windings, is generated.

Consequently, the current flowing through the output transistor is equal to the current current, multiplied by the reverse ratio of the turns (transformation coefficient). It is the maximum current that can pass through the transistor, and determines the maximum power of the converter.

There are two ways to increase the power of the inverter: either apply more powerful transistoror apply parallel inclusion Several less powerful transistors in one shoulder. For a homemade converter, a second method is preferable, as it allows not only to apply cheaper parts, but also retains the performance of the converter when the transistor fails. In the absence of built-in overload protection, such a solution will significantly increase the reliability of the homemade device. It will reduce the heating of transistors when they work on the previous load.

On the example of the last scheme it will look like this:

Automatic shutdown when battery discharge

The absence of a device in the converter scheme automatically turning it off at a critical supply of supply voltage, can seriously bring youif you leave such an inverter connected to the car battery. Complete the homemade inverter automatic control will be extremely useful.

Simpled circuit breaker Loads can be made from a car relay:

As is known, each relay has a certain voltage at which its contacts are closed. The selection of resistance resistor R1 (it will be about 10% of the resistance of the relay winding) the moment is configured when the relay breaks the contacts and stop the flow of the current to the inverter.

EXAMPLE: Take the relay with the voltage of the response (U p) 9 volts and winding resistance (R o) 330 ohms. So that it is triggered at a voltage above 11 volts (U Min), consistently with the winding you need to include resistor resistorR n, calculated from the conditions of equalityU r /R o \u003d (U Min -U p) /R n. In our case, a resistor at 73 Ohm will be required, the nearest standard nominal value is 68 ohms.Of course, this device is extremely primitive and is rather warmth for the mind. For more stable work It must be supplemented with a simple control circuit that supports the trip threshold much more accurately:

Read the same: Talk about 10 kW voltage stabilizers for home

Adjustment of the trigger threshold is carried out by the selection of the resistor R3.

We offer to watch a video on the topic

Inverter fault detection

Listed simple schemes have the two most common faults - either there is no voltage at the transformer output, or it is too small.

I decided to enjoy a separate article by the manufacture of DC AC of a voltage converter by 220V. This of course is remotely related to the topic. lED searchlights and lamps, but such a mobile power supply is widely used at home and in the car

- 1. Assembly options

- 2. Stress converter design

- 3. Sinusoid

- 4. Example of the filling of the converter

- 5. Build from UPS

- 6. Build from finished blocks

- 7. Radio constructors

- 8. Schemes of powerful converters

Assembly options

There are 3 optimal methods of manufacturing inverter 12 in 220 with your own hands:

- assembly from finished blocks or radio constructors;

- manufacture of uninterruptible power supply;

- use of radio amateur schemes.

In the Chinese, you can find good radio constructors and ready-made blocks for assembling DC converters to a variable 220V. For the price this method will be the most cost, but is required for a minimum of time.

The second way is the upgrade of the uninterruptible power supply (UPS), which without battery in large quantities Sold on Avito and stand from 100 to 300 rubles.

The most difficult version is the assembly from zero, without radio amateur experience can not do. We will have to make printed circuit boards, select components, a lot of work.

Stress converter design

Consider the design of the usual voltage converter from 12 to 220. The principle of operation for all modern inverters will be the same. High-frequency PWM controller sets operation, frequency and amplitude. The power part is made on powerful transistors, heat from which is given to the device body.

The input is installed a fuse protecting against short circuit Car battery. Next to the transistors, the thermal sensor is attached, which monitors their heating. In the case of overheating inverter 12V 220V, the active cooling system consists of one or more fans. IN budget models The fan can work constantly, and not only at high load.

Silest transistors at the exit

Silest transistors at the exit

Sinusoid

The waveform at the outlet of the car inverter is formed by a high-frequency generator. The sinusoid can be two types:

- modified sinusoid;

- pure sinusoid, pure sine.

Not every electric device can operate with a modified sinusoid, which has a rectangular shape. In some components, the mode of operation changes, they can heat up and start shabby. Looking like you can get if you dimmize lED lampwhich is not adjustable brightness. Begins crackling and blinking.

Dear DC AC Rapid voltage converters 12V 220V have a clean sine at the output. It is much more expensive, but the electrical appliances work fine with it.

An example of the filling of the converter

Assembly from UPS

So that nothing to invent and not buy finished modules, You can try a computer uninterruptible power supply, abbreviated IPB. They are designed for 300-600W. I have Ippon on 6 sockets, connected 2 monitors, 1 Systems, 1Televisor, 3 surveillance cameras, video surveillance control system. Periodically translate to the operating mode by disconnecting from the network 220 so that the battery is discharged, otherwise the service life is strongly reduced.

Electrician colleagues connected the usual car acid accumulator to the uninterrupted man, worked perfectly for 6 hours, watched football in the country. The UPS is usually embedded in the diagnostic system of the gel battery, which determines its low container. How it will react to the car is unknown, although the main difference is the gel instead of acid.

Filling UPS

Filling UPS

The only problem, uninterrupted can not like races in the automotive network with the engineered engine. For a real radio amateur, this problem is solved. You can only be used with a plugged engine.

Mostly the UPS are designed for short-term work when 220V disappears in the outlet. With long permanent work It is very advisable to put active cooling. Ventilation is useful for the stationary option and for the car inverter.

Like all the devices, it is unpredictable to behave when starting the engine with a connected load. The starter of the car is very leaving the volts, at best she will go to defense as when the battery is out. At worst there will be jumps at the outlet 220V, the sinusoid will distort.

Building from finished blocks

To assemble a stationary or automotive inverter of 12V 220V, you can use ready-made blocks that are sold on the Ebey or the Chinese. It will save time on the manufacture of boards, soldering and final tuning. It is enough to add a housing to them and wire crocodiles.

You can also purchase a radio constructor, which is equipped with all radio components, can only be soldered.

Approximate price for autumn 2016:

- 300W - 400 rub;

- 500W - 700 rub;

- 1000W - 1500rub;

- 2000W - 1700rub;

- 3000W - 2500 rub.

Search on Aliexpress Select a request in the search bar "Inverter 220 DIY". Reduction "DIY" means for the "assembly with their own hands."

500W fee, yield to 160, 220, 380 volts

500W fee, yield to 160, 220, 380 volts

Radio constructures

The radio constructor is cheaper than the finished fee. The most complex elements can be already on the board. After assembly, it practically does not require configuration for which the oscilloscope is necessary. The variation of the parameters of the radio components and the nominal nominations are not bad. Sometimes there is a spare part in the bag, suddenly inexperienced the leg will tear up.

Schemes of powerful converters

The powerful inverter is mainly used to connect building power to the construction of cottages or phasendes. A low-power voltage converter by 500W from a powerful to 5000 - 10000 watts is characterized by the number of transformers and power transistors at the output. Therefore, the complexity of manufacture and the price is almost the same, transistors are inexpensive. Power is optimally 3000W, you can connect a drill, a grinder and another tool.

I will show several inverters schemes from 12, 24, 36 to 220V. Such to put in a passenger car are not recommended, you can randomly install the electrician. DC AC converter circuit equipment 12 to 220 simple, specifying generator and power part. The generator is made on popular TL494 or analogs.

A large number of raising schemes from 12V 220V for manufacture with your own hands can be found by reference

http://cxema.my1.ru/publ/istochniki_pitanija/preprezozovateli_naprjazhenija/101-4

There are only about 140 schemes there, half of them increase converters from 12, 24 to 220V. Power from 50 to 5000W.

After the assembly, the entire scheme is required using an oscilloscope, it is desirable to have experience with high-voltage schemes.

To build a powerful inverter, 2500 watts will require 16 transistors and 4 suitable transformer. The cost of the product will be a considerable, comparable with the cost of a similar radio constructor. The advantage of such costs will be pure sine at the exit.

Many radio amateurs are both motorists and love to relax with friends in nature, and I don't want to refuse the benefits of civilization. Therefore, they collect with their own hands the voltage converter 12 220 of which is considered in the figures below. In this article, I will tell and show the various options for the inverter designs, which are used to obtain a 220 volt network voltage from car battery.

The device is built on a two-stroke inverter on two powerful field transistors. Any N-channels will be suitable for this design. field transistors With a current of 40 amps and more, I applied inexpensive IRFZ44 / 46/48 transistors, but if you need a high power better use more powerful field transistors.

The transformer wakes on the ferrite ring or an E50 armored core, and you can also at any other. The primary winding should be coated by two vehicle with a cross section of 0.8 mm - 15 turns. If you use the armor core with two sections on the frame, the primary winding is dulling in one of the sections, and the secondary consists of 110-120 turns of the copper wire 0.3-0.4 mm. At the output of the transformer, we obtain an alternating voltage in the range of 190-260 volts, rectangular pulses.

Voltage converter 12 220 of which was described, can feed various loads, the power of which is not more than 100 watts

Output pulse shape - rectangular

The transformer in the diagram with two primary windings by 7 volts (each shoulder) and a 220 volt network winding. Almost any transformers are suitable from uninterrupted, but with a capacity of 300 watts. The diameter of the wire of the primary winding of 2.5 mm.

The IRFZ44 transistors in their absence can be easily replaced with IRFZ40,46,48 and even more powerful - IRF3205, IRL3705. Transistors in the TIP41 multivibrator scheme (KT819) can be replaced with domestic CT805, KT815, KT817, etc.

Attention, the scheme does not have protection at the output and input from short circuit or overload, the keys will overheat or burned.

Two design options pCB And the photo of the finished converter can be downloaded on the link above.

This converter is quite powerful and it can be applied to power the soldering iron, grinder, microwaves and other devices. But do not forget that its operating frequency is not 50 hertz.

The primary transformer winding is winding up with 7-veins immediately, with a wire with a diameter of 0.6 mm and contains 10 turns with a tap from the middle stretched across the Ferrite Ring. After the winding, the winding is insulating and begin to wind up the rising, the same wire, but already 80 turns.

Power transistors are preferably installed on heat sinks. If you collect a circuit of the converter correctly, it should earn immediately and the settings do not require.

As in the previous design, the heart of the scheme is TL494.

This is the finished two-stroke device. pulse converterFull of the domestic analog it is 1114EU4. At the output of the circuit, highly efficient rectifier diodes and a C-filter were applied.

In the converter, I applied a ferrite W-shaped core from a TPI TV transformer. All native windings were opened, because I got up to the secondary winding of 84 turns with a wire of 0.6 in enamel isolation, then a layer of isolation and move to the primary winding: 4 turns of an oblique from 8 reasons 0.6, after winding winding were called And they are divided by half, it turned out 2 windings of 4 turns in 4 wires, the beginning of one connected with the end of another, because I made a removal from the middle, and at the end I won the feedback winding with five turns of the wire of PAL 0.3.

Voltage converter 12 220 The scheme that we considered includes in its composition choke. It can be made with your own hands wound on a ferrite ring from a computer unit with a diameter of 10mm and 20 turns with a wire of PAL 2.

There is also a drawing of a circuit board of a voltage converter 12 220 volts:

And a few pictures of the received converter 12-220 volts:

Again, I liked TL494 in a pair with Mosfetas (this modern type of field transistors), the transformer this time I borrowed from the old computer unit of the power supply. When laying the board, I took into account the conclusions of it, so at its accommodation, be alert.

For the manufacture of the housing, I used a 0.25L jar from under the soda, so successfully squealed after the flight from Vladivostok, we cut the top ring from Vladivostok, and cut the middle of it, in it on the epoxy, glue from a fiberglass with holes for a switch and a connector.

To give a rigging bank, cut out a strip of a width with our housing out of a plastic bottle, and squeezed it with epoxy glue placed in a jar, after drying the jacket of the bank became quite rigid and with insulated walls, the bottom of the banks left clean, for better thermal contact with the transistor radiator.

At the end of the assembly, the wires soldered to the lid, I secured it with a thermoclaim, this will allow, if there is a need to disassemble the voltage converter, simply heating the lid with a hairdryer.

The converter design is designed to convert 12 volt voltage from a battery in 220 volts of variable with a frequency of 50 Hz. The idea of \u200b\u200bthe scheme is borrowed from 1989.

The radio amateur design contains the specifying generator calculated on the frequency of 100 Hz on the K561TM2 trigger, the frequency divider by 2 on the same chip, but on the second trigger and the power amplifier on the transistors loaded by the transformer.

Transistors considering output power The voltage converter should be installed on radiators with a large cooling area.

The transformer can be rewinded from the old network transformer TS-180. Network winding can be used as secondary, and then winding Ia and IB are wound.

The voltage converter assembled from the working components does not require establishing, with the exception of the selection of C7 condenser when the load is connected.

If the drawing of the printed circuit board is required, click on the PP pattern.

The signals from the microcontroller PIC16F628A through the resistance of 470 ohms control the power transistors, forcing them alternately open. In the source chains of field tropsistors are connected half-winding of the transformer power 500-1000 WA. On its secondary windings should be 10 volts. If you take a wire with a cross section of 3 mm.kv, then the output power will be about 500 W.

The whole design is obtained very compact, so you can use a batch fee, without etching tracks. Archive with microcontroller firmware Catch the green link just above

The circuit of the converter 12-220 is made on the generator that creates symmetric pulses, the following anti-phase and output block implemented on the field keys, which are connected to a raising transformer. On the elements of DD1.1 and DD1.2, a multivibrator generates the pulses with a frequency of 100 Hz is assembled according to the classic scheme.

To form symmetric pulses going in antiphase, the diagram uses the CD4013 chipger D-trigger. He divides on two all impulses falling on his entrance. If we have a signal going to an input with a frequency of 100 Hz, then at the output of the trigger will be only 50Hz.

Since the field transistors have an isolated shutter, the active resistance between their channel and the shutter seeks an infinitely large value. To protect the outputs of the trigger from overload in the circuit, there are two buffer elements DD1.3 and DD1.4, through which pulses follow the field transistors.

In the flow of the transistors, an increases transformer enabled. To protect against self-induction of self-induction in the drains of them are connected to Stabilians increased power. Suppression of RF interference is carried out by filter on R4, C3.

L1 choke winding is made with your own hands on a ferrite ring with a diameter of 28mm. It is wrapped with a wire with a PAL-2 0.6 mm with one layer. The transformer is the most common network for 220 volts, but the capacity is not lower than 100W and having two secondary windings on 9V each.

To increase the efficiency of the voltage converter and prevent strong overheating, field transistors with low resistance are used in the output cascade of the inverter.

On DD1.1 - DD1.3, C1, R1, a rectangular pulse generator was made with a frequency of pulses of 200 Hz. The pulses are then enrolled on the frequency divider built on the elements DD2.1 - DD2.2. Therefore, at the output of the divider 6 output DD2.1, the frequency is reduced to 100 Hz, and already 8 output DD2.2. It is 50 Hz.

Signal with 8 output DD1 and C 6 output DD2 follows VD1 and VD2 diodes. To complete the opening of field transistors, it is necessary to increase the amplitude of the signal, which passes from VD1 and VD2 diodes, for this in the voltage converter diagram VT1 and VT2 are applied. Through VT3 and VT4, field output transistors are controlled. If there were no errors in the process of assembling the inverter, it starts to work immediately after power supply. The only thing is that it is recommended to make it pick up the rating of resistance R1 so that the output was the usual 50 Hz. VT5 and VT6. When a low level appears at Q1 (or Q2) output, the transistors VT1 and VT3 (or VT2 and VT4) will open, and the shutter containers begin to discharge, and the transistors VT5 and VT6 are closed.

Actually the converter is assembled according to the classic two-stroke scheme.

If the voltage at the converter output exceeds the set value, the R12 resistor voltage will be higher than 2.5 V, and therefore the current via the DA3 stabilizer will increase dramatically and the high-level signal at the DA1 chip input will appear.

Its Outputs Q1 and Q2 will switch to zero state and field transistors VT5 and VT6 will close, causing a decrease in the output voltage.

The voltage converter circuit also added a current protection unit based on the K1 relay. If the current flowing through the winding will be higher than the set value, the contacts of Hercon K1.1 will work. At the entrance of the FC chip DA1 will be high level And its outputs will switch to a low level state, causing the closing of VT5 and VT6 transistors and a sharp decrease in current consumed.

After that, DA1 will remain in the locked state. To start the converter, the voltage drop in the input input will be required, which can be achieved either by power outage or short-term closure of C1 containers. To do this, you can enter the button without fixing, the contacts of which solder parallel to the condenser.

Because the output voltage is meander, the C8 capacitor is intended for its smoothing. The HL1 LED is necessary to indicate the presence of the output voltage.

The T1 transformer is made of TS-180, it can be found in the power blocks of old kinescopic TVs. All of its secondary windings are removed, and the mains on the voltage is 220 V. It serves as an output winding of the converter. Semobype 1.1 and I.2 are made from the wires of the PEV-2 1.8 to 35 turns. The beginning of one winding is connected with the end of another.

The relay is homemade. Its winding consists of 1-2 turns of an isolated wire, designed for current up to 20 ... 30 A. Wires on the housing of the Herron with closing contacts.

The selection of the resistor R3, you can set the desired frequency of the output voltage, and the R12 resistor - amplitude from 215 ... 220 V.

Circuits of simple voltage converters based on car generators are built using transistors.

In generators with self-excitation (auto beams) for excitation electric oscillations Typically used positive feedback. There are also autogenerators on active elements with negative dynamic resistance, but they are practically not used as converters.

Single-sketched voltage converters

Most simple scheme The single-circuit voltage converter based on the autogenerator is shown in Fig. 1. This type of generators received the name of the block generators. Phase shift To ensure the conditions for the occurrence of oscillations in it is ensured by a certain turning on the windings.

Fig. 1. Scheme of a voltage converter with transformer feedback.

Analogue of the transistor 2N3055 - KT819GM. The block generator allows you to get short pulses with high duty. In the form, these impulses are approaching rectangular.

The capacitance of the oscillatory contours of the blocking gene-raster is usually small and due to the intersensive tanks and the installation capacity. The limiting frequency of the generation of the Blank generator is hundreds of kHz. The disadvantage of this type of generators is the pronounced dependence of the generation frequency of the supply voltage.

Resistive divider in the transistor transistor base circuit (Fig. 1) is designed to create an initial displacement. Several modified variant of the transformer feedback converter is shown in Fig. 2.

Fig. 2. Scheme of the main (intermediate) block of the source of high voltage voltage based on the autogenerator transducer.

The autogenerator operates at a frequency of about 30 kHz. At the output of the converter, an amplitude voltage is formed to 1 kV (determined by the number of turns of the transformer increases).

The T1 transformer is made on a dielectric frame inserting in armor core B26 from ferrite M2000NM1 (M1500HM1). Primary winding contains 6 turns; Secondary winding - 20 turns of the wire PELSHO with a diameter of 0.18 mm (0.12 ... 0.23 mm).

The increase in the winding to achieve the output voltage of the value of 700 ... 800 B has about 1800 turns of the wire of the PAL with a diameter of 0.1 mm. After every 400 turns, the dielectric gasket from condenser paper is stacked, the layers are impregnated with condenser or transformer oil. The conclusions of the coil are poured with paraffin.

This converter can be used as an intermediate for powering subsequent formation steps. high voltage (for example with electrical arresters or thyristors).

The following voltage converter (USA) is also made on a single transistor (Fig. 3). Stabilization of the bias voltage of the base is carried out by three successively included diodes VD1 - VD3 (direct displacement).

Fig. 3. Scheme of a voltage converter with transformer feedback.

The collector transition of the VT1 transistor is protected by a C2 capacitor, in addition, a chain from the VD4 diode and Zebabitron VD5 is connected parallel to the collector winding of the transformer T1.

The generator generates pulses, shaped close to rectangular. The generation frequency is 10 kHz and determines the value of the capacitor capacitor of the SZ. Analogue of the transistor 2N3700 - CT630A.

Two-stroke voltage converters

The diagram of the two-stroke transformer voltage converter is shown in Fig. 4. Analogue of the transistor 2N3055 - CT819GM. A high-voltage transformer transformer (Fig. 4) can be made using a ferrite unlocked round or rectangular core, as well as based on a television line transformer.

When using a round-shaped ferrite core with a diameter of 8 mm, the number of high-voltage winding turns depending on the required value of the output voltage can reach 8000 turns of the wire with a diameter of 0.15 ... 0.25 mm. Collector windings contain 14 turns of the wire with a diameter of 0.5 ... 0.8 mm.

Fig. 4. Scheme of a two-stroke transformer with transformer feedback.

Fig. 5. Options for a high-voltage converter circuit with transformer feedback.

Feedback windings (basic windings) contain 6 turns of the same wire. When connecting windings, their phasing should be observed. Output voltage of the converter - up to 8 square meters.

As transistors of the converter, transistors of domestic production can be used, for example, KT819 and them like.

The variant of the diagram of a similar voltage converter is shown in Fig. 5. The main difference lies in the circuits of the displacement of the transistors.

The number of turns of the primary (collector) winding - 2x5 turns with a diameter of 1.29 mm, secondary - 2x2 turns with a diameter of 0.64 mm. The output voltage of the converter is entirely determined by the number of turns of the rising winding and can reach 10 ... 30 square meters.

The voltage converter A. Chaplygin does not contain resistors (Fig. 6). It feeds from the battery with a voltage of 5 6 and is able to give to the load to 1 A at a voltage of 12 V.

Fig. 6. Scheme of a simple high efficiency voltage converter with a battery from 5 V.

The rectifier diodes serve transistors of the autogenerator. The device is capable of working and under reduced to 1 in the supply voltage.

For low-power transformations of the converter, you can use CT208 type transistors, CT209, KT501 and others. The maximum load current should not exceed the maximum current of the transistor base.

Diodes VD1 and VD2 are not required, however, it is possible to obtain an additional voltage of 4.2 in negative polarity. The efficiency of the device is about 85%. The T1 transformer is made on the K18X8X5 2000HM1 ring. Winding I and II have 6, III and IV - 10 turns of the wire of the PAL-2 0.5.

Converter according to the inductive three-dimensional scheme

The voltage converter (Fig. 7) is made according to the inductive three-dimensional scheme and is designed to measure high-resistance and allows you to obtain a non-stabilized voltage 120 ... 150 V.

Current converter Current about 3 ... 5 mA With a supply voltage of 4.5 V. The transformer for this device can be created based on the BTK-70 television transformer.

Fig. 7. Scheme of the voltage converter according to the inductive three-shock scheme.

Its secondary winding is removed, the low-voltage winding of the converter is winding - 90 turns (two layers of 45 turns) of the wires of the PEV-1 0.19 ... 0.23 mm. The discharge from the 70th turn from the bottom according to the scheme. Resistor R1 - the value of 12 ... 51 com.

1.5 V / -9 voltage converter in

Fig. 8. Voltage converter diagram 1.5 V / -9 V.

The converter (Fig. 8) is a uniform relaxation generator with a capacitive positive feedback (C2, SZ). The collector chain of the transistor VT2 includes an increase in autotransformer T1.

The converter uses the reverse inclusion of the rectifier diode VD1, i.e. for open transistor VT2 The voltage of the autotransformer is applied to the autotransformer winding, and the voltage pulse appears at the autotransformer output. However, the VD1 diode included in the opposite direction at this time is closed, and the load is disconnected from the converter.

At the moment of the pause, when the transistor closes, the polarity of the voltage on the windings of T1 changes to the opposite, the Diode VD1 opens, and the straightened voltage is applied to the load.

With subsequent cycles, when the VT2 transistor is locked, filter capacitors (C4, C5) are discharged through the load, ensuring the flow direct current. The inductance of the raising winding of the autotransformer T1 at the same time plays the role of the smoothing filter throttle.

To eliminate the velocity of the vehicles of the vehicles of the vehicle transformer, the VT2 transistor is used to magnify the autotransformer core due to the inclusion in parallel to its winding of C2 and SZ capacitors, which are simultaneously the feedback voltage divider.

When the VT2 transistor closes, C2 capacitors and SZ during the pause are discharged through part of the transformer winding, the magnetizing core T1 discharge current.

The generation frequency depends on the voltage based on the transistor ѵT1. The stabilization of the output voltage is carried out due to negative feedback (OOS) on constant voltage by R2.

When the output voltage decreases, the frequency of generated pulses is increasing at the same time of their duration. As a result, the frequency of recharging the C4 and C5 filter capacitor is increasing and the voltage drop on the load is compensated. With an increase in the output voltage, the generation frequency, on the contrary, decreases.

So, after charge of the cumulative capacitor C5, the generation frequency falls in tens of times. There are only rare impulses that compensate for the discharge of capacitors in rest mode. This method of stabilization made it possible to reduce the converter rest current up to 0.5 mA.

Transistors ѵT1 and ѵT2 should have a greater gain of the gain to increase the cost-effectiveness. The winding of the autotransformer is wound on the Ferrite ring K10x6x2 from the 2000 NMM material and has 300 turns of the wire PAL-0.08 with a tap from the 50th turn (counting from the "grounded" output). The VD1 diode must be high-frequency and have a small reverse current. The establishment of the converter is reduced to the setting of the output voltage equal to -9 in the selection of the resistor R2.

PWM voltage converter

In fig. 9 shows a diagram of a stabilized voltage converter with pulse control. The converter retains performance with a decrease in the battery voltage from 9 .... 12 to 3V. Such a converter is most suitable for battery power equipment.

KPD stabilizer - at least 70%. Stabilization is saved with a decrease in the power supply voltage below the output stabilized voltage of the converter, which can not provide a traditional voltage stabilizer. The principle of stabilization used in this voltage converter.

Fig. 9. Scheme of the stabilized voltage converter with PWM control.

When the current converter is turned on through the resistor R1, the transistor ѵT1 opens the collector current of which, flowing through the winding of the II transformer T1, opens the powerful transistor ѵT2. The transistor ѵT2 enters the saturation mode, and the current through the winding of the I transformer is linearly increasing.

In the transformer there is an accumulation of energy. After some time, the transistor ѵT2 goes into active mode, in the windings of the transformer there is an emf of self-induction, the polarity of which is opposite to the voltage applied to them (the transformer magnetic curtain is not saturated).

The transistor ѵt2 is avalanche-like closed and EMF self-induction of winding I through the VD2 diode charges the capacitor SZ. Capacitor C2 contributes to a clearer closing of the transistor. Next, the process is repeated.

After some time, the voltage on the SZ condenser increases so much that the VD1 stabilitron opens, and the transistor current current is decreased, while the base current is reduced, which means the collector current of the transistor ѵT2.

Since the energy accumulated in the transformer is determined by the collector current of the transistor ѵT2, the further increase in the voltage on the SZ condenser stops. The capacitor is discharged through the load. Thus, at the output of the converter supported constant pressure. The output voltage sets the VD1 stabilitron. The transformation frequency varies within 20 ... 140 kHz.

Voltage converter 3-12V / + 15V, -15V

The voltage converter, the diagram of which is shown in Fig. 10, it is distinguished by the fact that in it the load circuit is galvanically unleashed from the control circuit. This allows you to get several secondary stable stresses. The use of an integrating link in the feedback circuit makes it possible to improve the stabilization of the secondary voltage.

Fig. 10. Scheme of the stabilized voltage converter with a bipolar output 15 + 15V.

The frequency of the conversion decreases almost linearly with a decrease in the supply voltage. This circumstance strengthens feedback In the converter and increases the stability of the secondary voltage.

The stress on the smoothing capacitors of secondary circuits depends on the energy of the pulses obtained from the transformer. The presence of the resistor R2 makes the voltage on the cumulative capacitor C3 dependent and on the frequency of the pulse followed, and the degree of dependence (steepness) is determined by the resistance of this resistor.

Thus, the r2 trimming resistor can be set up the desired dependence of voltage change. secondary windings From changing supply voltage. Field transistor ѵT2 - current stabilizer. The efficiency of the converter can reach 70 ... 90%.

The instability of the output voltage at a supply voltage of 4 ... 12 to no more than 0.5%, and when the ambient temperature change from -40 to + 50 ° C is not more than 1.5%. Maximum load power - 2 W.

When the converter is established, the R1 and R2 resistors are set to the minimum resistance position and the Equivalents of the RH loads are connected. The input of the device is supplied to the supply voltage 12 V and using a resistor R1 on the load of RN. Voltage 15 V. Next, the supply voltage is reduced to 4V and the R2 resistor achieves the output voltage also 15 V. Repeating this process several times, achieve a stable output voltage.

Winding I and II and a transformer magnetic core in both options transducers are the same. Winding wound on armored magnetic circuit B26 from ferrite 1500NM. The winding I contains 8 turns of the wire of the PAL 0.8, and II - 6 turns of the wire of the PAL 0.33 (each of the windings III and IV consists of 15 turns of the wire of the PAL 0.33 mm).

Low-sized network voltage converter

The scheme of a simple small-sized network voltage converter made from the available elements is shown in Fig. 11. At the base of the device, a regular block generator on the VT1 transistor (CT604, CT605A, KT940).

Fig. 11. Scheme of a downgrade voltage converter based on a block generator.

The T1 transformer is wound on the B22 armored core from ferrite M2000nn. The windings of ІА and _b contain 150 + 120 turns of the wire PELSHO 0.1 mm. Winding II has 40 turns of the wire of the PAL 0.27 mm III - 11 turns of the PELSHO wire 0.1 mm. Initially, the winding of the iA is wound, then - II, after - LB winding, and finally winding III.

The power source is not afraid of a short circuit or a break in the load, however, it has a large voltage ripple ratio, low efficiency, a small output power (up to 1 W) and a significant level of electromagnetic interference. You can feed the converter from a DC source 120 6. In this case, the resistors R1 and R2 (as well as the Diode VD1) should be excluded from the circuit.

Low-current voltage converter by 440V

The low-current voltage converter for powering a gas-discharge meter of Geiger Muller can be assembled according to the scheme in Fig. 12. The converter is a transistor block generator with an additional increases winding. Pulses with this winding charge Condenser SZ through rectifier diodes VD2, VD3 to voltage 440 V.

Condenser SZ must be either saliva or ceramic, on work voltage Not lower than 500 V. The duration of the pulse of the block generator is approximately 10 μs. The frequency of pulses (tens of Hz) depends on the time constant of the chain R1, C2.

Fig. 12. Scheme of a low-voltage voltage converter for powering a gas-discharge meter of Geiger Muller.

The T1 transformer magnetic circuit breeding is made of two cooled Ferrite rings to K16x10x4.5 3000nm and isolate its layer of lacketcloth, teflon or fluoroplast.

At the beginning, the winding III - 420 turns of the PEV-2 wire 0.07, filling the magnetic curtain of the magnetic circuit, was wound. Over the winding III impose a layer of insulation. Winding I (8 turns) and II (3 turns) are wound with any wire over this layer, they should also be easily distributed over the ring.

You should pay attention to the correct phasing of the windings, it must be completed before the first inclusion. With the resistance of the load of the order of units, the converter consumes current 0.4 ... 1.0 mA.

Voltage converter to power photo flash

Voltage converter (Fig. 13) is designed to power the photo flash. The T1 transformer is made on the magnetic line of two folded permalloic rings K40X28X6. The winding circuit of the transistor VT1 has 16 turns of PEV-2 0.6 mm; Its basic chain is 12 turns of the same wire. The rising winding contains 400 turns of PEV-2 0.2.

Fig. 13. Voltage converter circuit for photo flash.

The HL1 neon lamp is used from the starter of the daylight lamp. The output voltage of the converter smoothly rises on the photographes condenser to 200 in 50 seconds. The device consumes current to 0.6 A.

PN-70 voltage converter

To power the lamp flashes, the PN-70 voltage converter is intended, which is the basis of the device described below (Fig. 14). Usually the energy of the transducer batteries is spent with minimal efficiency.

Regardless of the frequency of flashes of light, the generator works continuously, spending a large number of Energy and discharge batteries.

Fig. 14. Scheme of the modified voltage converter Mon-70.

Translate the operation of the converter into the waiting mode was managed by O. Packovik, which turned on the resistive divider R5, R6 at the converter output and filed a signal from it through the VD1 stabitron on electronic keyMade on transistors VT1 - ѵTZ according to the Darlington scheme.

Once the voltage on the capacitor of the photo message (on the diagram is not shown) reaches the nominal value determined by the R6 resistor value, the VD1 stabilitron breaks, and the transistor key will turn off the power battery (9 V) from the converter.

When the voltage at the output of the converter drops as a result of the self-discharge or discharge of the capacitor on the flash lamp, the VD1 stabilitron will stop conducting the current, the key turns on and, respectively, the converter. The transistor ѵT1 must be installed on a copper radiator with dimensions 50x22x0.5 mm.

In this article you can get acquainted with the detailed step by step instructions For the manufacture of an AC inverter by 220 V 50Hz from a car battery to 12 V. Such a device is able to produce power from 150 to 300W.

Scheme this device Sufficient enough.

This scheme works on the principle of PUSH-PULL converters. The heart of the device will serve the CD-4047 board working as a specifying generator, and also controls the field transistors that work in the key mode. Only one transistor can be opened, if two transistors are open at one time, a closure will occur, as a result of which the transistors are burned, it can also occur in case of incorrect control.

The CD-4047 fee is not designed for high-precision field transistors, but it copes with this task perfectly. Also, the device also requires a transformer from an old UPS to 250 or 300W with a primary winding and an average plus connection point from the power supply.

The transformer has a sufficiently large number of secondary windings, you will need to measure all the taps using a voltmeter and find a 220V network winding. The wires you need will produce the largest electrical resistance of approximately 17 ohms, you can delete unnecessary gag.

Before starting to solder, it is advisable to double-check again. It is recommended to choose transistors from one batch and the same characteristics, the condenser of the frequently specifying chain to have a small leak and a narrow tolerance. Such characteristics are determined by the tester for transistors.

Since the CD-4047 fee there are no analogues, it is necessary to purchase it precisely, but the field transistors if necessary can be changed to N-channels with a voltage from 60V and a current at least 35a. Suitable from the IRFZ series.

Also, the scheme can work using bipolar transistors at the output, but it should be noted that the power of the device will become much smaller, if compared with the scheme on which the bevels are used.

Restricted gate resistors must have a resistance of 10-100 ohms, but it is preferable to use resistors at 22-47 ohms of which is 250 MW.

A often specifying chain is assembled exclusively from the elements specified in the diagram, which has accurate settings by 50Hz.

If you bring the device correctly, it will work from the first seconds, but when you first start it is important to progress. To do this, instead of the fuse (watch the circuit), you need to install a resistor of which is 5-10 ohms or a light bulb for 12V, in order to avoid explosion of transistors if errors were made.

If the device works stable, then the transformer will make a sound, but the keys will not be warm. If everything works correctly, the resistor (light bulb) must be removed, and the power is supplied through the fuse.

In the middle inverter consumes energy during idle robot from 150 to 300 mA depending on which power supply and type of transformer.

Then you need to measure the output voltage, at the output should be about 210-260V, it is considered a normal indicator, since the inverter does not have stabilization. Next, you need to check the device, under the load connecting the light bulb 60 watts and give to work 10-15 seconds, the keys during this time are slightly warm up, since they do not have heat sinks. The keys must be basically evenly, in the case of non-uniform heating, you need to search where errors are made.

We supply the inverter with the Remote Control function

The main advantage wire should be connected to the middle point of the transformer, but that the device starts to work, you need to connect a low-current plus to the board. This will start a pulse generator.

A couple of proposals about the installation. Everything is installed in the power supply housing for computers, transistors should be installed on separate radiators.

If a common heat sink is installed, be sure to insulate the case of the transistors from the radiator. The cooler is connected to the bus on 12V.

One of the essential drawbacks of this inverter is the lack of protection against closure and if it occurs, then all transistors burned. In order to prevent this, you will definitely need to install the fuse on 1A.

To start the inverter, use no high power button through which plus will be fed. Transformer power tires should be fixed directly to transistor radiators.

If you connect the energy meter to the output of the converter, then it can see that the outgoing frequency and voltage within the permissible one. If you have the value more or less than 50 Hz, it must be configured using a multi-turn variable resistor, it is installed on the board.

Magnetometry in the simplest version The ferrozond consists of a ferromagnetic core and two coils on it

Magnetometry in the simplest version The ferrozond consists of a ferromagnetic core and two coils on it Effective job search course search

Effective job search course search The main characteristics and parameters of the photodiode

The main characteristics and parameters of the photodiode How to edit PDF (five applications to change PDF files) How to delete individual pages from PDF

How to edit PDF (five applications to change PDF files) How to delete individual pages from PDF Why the fired program window is long unfolded?

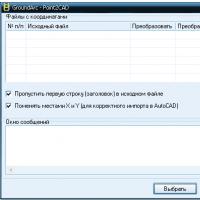

Why the fired program window is long unfolded? DXF2TXT - export and translation of the text from AutoCAD to display a dwg traffic point in TXT

DXF2TXT - export and translation of the text from AutoCAD to display a dwg traffic point in TXT What to do if the mouse cursor disappears

What to do if the mouse cursor disappears