Sound light indicators. Arrower devices - indicators. Video operation indicator

In the umzch, it looks beautiful and stylish, that's just where to find them ... There is a way out - we will make such a meter in which the role of the arrows will perform light-emitting diodes controlled by the microcircuit. LM3916.- This is a special microcircuit for LED level indicators.

Scheme of the Lightway LED Indicator

LEDs are connected via connectors J3 - J12 (only one series of LEDs is shown in the diagram). The indicator circuit will require a two-oarse power supply for proper work. The positive power potential of the LED line should be lower than +25 V and in combination with the voltage of the negative play, should not exceed 36 V. The minimum level of voltage depends on the operating voltage of the LEDs. For example, if the LED is 1.9 V, and we have 7 LEDs for one contact, then the minimum positive voltage will be 7 x 1.9 V + 1.5 V (voltage drop on LM3916) \u003d 14.8 volts. Green LEDs, as a rule, have a slightly higher voltage - 2.2-2.4 in, so that +18 B will be sufficient in most cases.

The LED current is determined by the R1_REF resistor, and with a resistance of 2.2 kΩ there will be 5 mA.

Formula for calculation: ILED \u003d 10 x (1.2 V / R1_REF)

As double operational amplifier At the entrance you can put - TL072, TL082, LM358. The output mode can be installed with a 3-pin jumper JP1. The maximum input voltage for LM3916 has a value of 1.2 V, and using R8-R7 you can adjust the level of the input signal.

Video operation indicator

LED color on your choice. Here are used green LEDs for negative levels, yellow - 0DB I. red For a positive level sound signal. This requires rectangular LEDs. Archive with pictures of printed circuit boards.

Output signal light indicators Currently, they are very popular, especially for using them in the modernization of rare equipment. Many radio amateurs perfectly remember the Soviet power amplifier Radiotehnika U-101 of the Riga Plant of the same name. In the early 80s, the plant began to release a new model, international standard (overall) musical complex "Radiotehnika K-101 Stereo". In general, this combine was a very good complex. But here is the amplifier, or rather the Toli output power indicator built in it was imperfect or there were errors in the design.

Nevertheless, when the device was new, then no complaints caused, but over time, he began to deliver some inconvenience with his non-clear and dull scale of the scale or in general in the control scheme, any element faced. Recently, I also became the owner of such an amplifier. Of course, I did not have a desire to restore the regular indicator, and initially I was already supposed to install in the arrow apparatus. Moreover, I had several pieces of such thing in the reserve, and there was not difficult to find them in my radio broadcasts. But no matter how I began to restore and partial upgrade to establish radiotehnika U-101 output light indicators on K157D1. P\u003e

Initially, he took three millimeter plastic and cut out 3 blanks of rectangular shape from it, and then with the help of dichloroethane, the indicators were glued together with each other. Plastic strips should be adjusted so that they are the same with the indicators in width and did not perform per perimeter. Here in the photo shows the design with a natural size of the window in the front panel of the power amplifier.

In the glass from the standard indicator, the windows made and dressed on new arrogant indicators. The glass is desirable to handle a small small file or a nadfel to the village tightly in its place. Next, glued all this again dichloroethane. Of course you need to do this whole operation very carefully, as it frontal panel And it should look, respectively.

Here is the responsible stage.

On top of the indicators, relative to the window in the glass, there is a small gap. So let him remain there, it will be convenient to place SMD LEDs for the backlight.

Now you need to solder wires to LEDs and put them in that gap, which is between the indicator and glass on a small amount of Super glue.

Cut from the plastic strip and attached it to the side walls. After it is still planted with glue, the design will gain even greater rigidity and will be the basis for installing a control board on it.

On this photo, the standard location for the installation of the indicator. There is also a red connector with wires. It is designed to supply power on the control board. It will certainly be needed in the future.

At this stage, the assembled module must try how it becomes. The fact is that this design is not attached by any screws, but simply presses the front panel to the chassis power amplifier. Therefore, you need to ensure the maximum dense landing. Under the wires coming from LEDs, the round nadfil should make a small cut into the chassis.

Circuit diagram and printed control module

Output power indicators amplifier

Showers The output power indicator is a beautiful and useful thing at the same time. In modern automotive amplifiers, they are used more and more often, even in budget models. But it's not always to look at this beauty, it's not always - it is usually in the trunk, so the benefit of it, to put it mildly, dubious. It is quite another thing if the indicator is on the instrument panel. However, while such a device in the "separate" version is only one - Mcintosh. The dimensions of His 1 DIN, the price is to be softer ... In general, it's time to do this miracle with your own hands, having only a multimeter in except for the soldering iron.All power indicators are connected to the output of the amplifier. You can use both separate indicators for each channel and the overall indicator of the total power of two or more channels. Such an indication is clearer and more convenient than separate through the channels. And if there are five channels or six, how many eyes need? In any case, it is not necessary to install more than two indicators. In the six-channel Mcintosh amplifier only two - one shows the power of the channels from the first to the fourth, the second - fifth and sixth, more powerful.

The following schemes are extremely simplified. The root side of this simplicity is the need to select the elements when setting up. This is quite acquitted with a "piece" manufacture, but these schemes are affordable for mass production.

Arrow indicators The shooter indicators are the most simple. For their manufacture, the minimum of parts and qualifications are required, especially if you use a "branded" measuring device with a beautiful scale. However, in our time, the manufacture of a self-made difficulty scale does not represent - it can be printed on the printer and paste on top of the old. As the basis, the easiest way is to use the arrogant indicators from the magnetointers of old types or small-sized panel measuring instruments of the magnetoelectric system with a current of full deviation 0.25 ... 1 mA. Electromagnetic system devices (for example, automotive voltmeters) and milliammeters with a current of complete deviation of more than 5 mA for our purposes are unsuitable.

Insofar as simple schemes The shooting indicators do not require power, you can connect them to the outputs of the amplifier according to the Mixed Mono scheme, which allows you to slightly reduce the number of parts (Fig. 1).

| Fig.1 |

In fig. 2 shows the scheme of the simplest indicator. If necessary, the number of channels can be increased by adding resistors and diodes, as shown by the dotted line. When using the indicator, together with the magnets amplifier, sequentially with resistors R1, R2, you need to include electrolytic capacitors with a capacity of 47 ... 100 μF ("plus" to a radio tape recorder). You can also use "Mixed Mono" (see Fig. 1), while the capacitors are not required, and the R2VD2 chain can be excluded.

The resistance of the resistor turned on sequentially with the device depends on the total deviation current. An approximate resistance value can be found according to the formula shown in the figure. The exact value should be adjusted when setting up by the desired deviation of the arrow at a given power. The remaining details can be used by any types. The smoothing electrolytic condenser must be designed for work voltage Not below 25 volts when measuring power up to 15 W and not lower than 50 volts - with greater power. Voltage supply is needed because the condenser is used in the chain alternating current. Selecting its container within 1 ... 100 μF, you can adjust the reverse time of the arrows for every taste.

The lack of a scheme is a small dynamic range not exceeding 10 dB. It is enough for a radio tape recorder, but when working with a high power amplifier, the arrow will deviate only at the signal peaks. In this case, it is better to apply the scheme shown in Fig.3.

Its main difference is the dynamic range extender on the VD1 diode and the HL1 LED. As soon as the straightened voltage on the C1 condenser reaches the value of 0.7 V, the diode opens and the further increase in the voltage is slowed down by the R3 resistor. Selecting its resistance within 100 Ohm ... 10 com, you can adjust the "stroke" of the scale in the middle part. The following restriction occurs at the time of the ignition of the LED and the further increase in the voltage is practically terminated. The LED can be used as an overload indicator. The resistance of the inlet resistors is determined by the maximum power of the amplifier and the current of the used LED. The calculated formula is shown in the figure, the exact resistance value should be adjusted by the moment of ignition of the LED at maximum power.

The resistance of the resistor included in series with the instrument can be found on the second formula. The exact value should be adjusted when setting up by the desired deviation of the arrow at the time of the ignition of the LED. The voltage on the Red LED is approximately 1.6 V, on a brighter yellow-orange - about 2.5 V. The remaining parts can be used by any types. The smoothing electrolytic capacitor should be designed for the operating voltage of 6.3 ... 10 V, since the voltage on it is limited by the LED. The indicator is connected in the same way as the previous one.

The dynamic range of such an indicator can be easily reduced to 20 dB, a special control circuit with a logarithmic amplifier is already required to further expand the dynamic range, and such a scheme is already out of the frames of the simplest.

LED Indianizors The design of the LED indicators is somewhat more complicated. Of course, when using a special control microcircuit, it can be simplified to the limit, but there was a small trouble. Most of these chip develops at the output of no more than 10 mA and the brightness of the LEDs under the conditions of the car may be insufficient. In addition, the most common chips with outputs for 5 LEDs, and this is only a "minimum program". Therefore, for our conditions, the scheme on discrete elements is preferable, it can be expanded without much effort.

The simplest indicator on the LEDs (Fig. 4) does not contain active elements and in nutrition therefore does not need. Connection - to a magnetol according to the Mixed Mono scheme or with a separator capacitor, to the amplifier - "Mixed Mono" or directly.

Fig. four

The scheme is extremely simple and does not require establishing. The only procedure is the selection of the resistor R7. The diagram shows the nominal to work with the built-in heater amplifiers. When working with an amplifier with a capacity of 40 ... 50 W Resistance to this resistor should be 270 ... 470 Ohm. Diodes VD1 ... VD7 - any silicon with direct voltage drop of 0.7 ... 1 V and permissible current of at least 300 mA.

LEDs any, but one type and color of the luminescence with a working current of 10 ... 15 mA. Since the LEDs are "feed on" from the output stage of the amplifier, their quantity and operating current can be enlarged in this scheme. Therefore, you have to choose "bright" LEDs or find such a place for the indicator where it will be protected from direct lighting. Another disadvantage simplest design - Small dynamic range.

To improve the work, an indicator is required with the control circuit. In addition to more freedom, in the choice of LEDs, you can create a scale of any type with simple means - from linear to logarithmic, or "stretch" only one site. The diagram of the indicator with a logarithmic scale is shown in Fig. 5. The dotted line shows the optional elements.

Fig. five

LEDs in this scheme are controlled by keys on the transistors VT1 ... VT5. The key trigger thresholds specify VD3 ... VD9 diodes. Selecting their number, you can change the dynamic range and the type of scale. The overall sensitivity of the indicator is determined by the inlet resistors. The figure shows approximate triggering thresholds for two schema options - with single and "dual" diodes. Basically, the measurement range is up to 30 W at a load of 4 ohms, with single diodes - up to 18 W.

The HL1 LED glows constantly, it denotes the beginning of the scale, HL6 is an overload indicator. C4 condenser delays 0.3 ... 0.5 sec. Folding out the LED, which makes it possible to notice even short-term overload. Copy capacitor C3 Determines the reverse time. It, by the way, depends on the number of luminous LEDs - the "column" from the maximum starts to subscribe quickly, and then "slows down." C1, C2 capacitors at the device input are only needed when working with a built-in magnetic amplifier. When working with a "normal" amplifier, they are excluded. The number of signals at the input can be increased by adding chains from the resistor and diode. The number of indication cells can be increased by simple "cloning", the main limitation - "threshold" diodes should be no more than 10 and there should be at least one diode between the bases of neighboring transistors.

LEDs can use any depending on the requirements - from single LEDs to LED assemblies and high-brightness panels. Therefore, the diagram presents the ratings of current-limiting resistors for different working currents. For the rest of the details no special requirements are presented, transistors can be used almost any n-P-N structures With scattering power at a collector at least 150 MW and a twofold reserve for the current collector. The current transmission coefficient of these transistors should be at least 50, and better - more than 100.

This scheme can be somewhat simplified, while new properties appear as a side effect, very useful for our purposes (Fig. 6).

Fig. 6.

Unlike the previous scheme, where transistor cells were turned on in parallel, the sequential inclusion of the "Stage" is used here. The threshold elements are the transistors themselves and they open in turn - "bottom-up". But in this case the trigger threshold depends on the supply voltage. The figure shows exemplary indicator trigger thresholds at a power supply of 11 V (left border of rectangles) and 15 V (right border). It can be seen that with increasing supply voltage, the limit of the maximum power indication is mostly shifted. In the case of using the amplifier, the power of which depends on the battery voltage (and such a lot), similar to "auto-calibration" can benefit.

However, this fee for this is the increased load on transistors. Through the bottom according to the transistor scheme, the current of all LEDs flows, so when using indicators with a current of more than 10 mA, transistors will also be required to be appropriate. "Cloning" of cells even more increases the non-uniformity of the scale. Therefore, 6-7 cells are the limit. The purpose of the remaining elements and the requirements for them are the same as in the previous scheme.

Lightly upgrading this scheme, we obtain other properties (Fig. 7). In this scheme, in contrast to the previously considered, there is no glowing "line". Only one LED is glowing at each time, imitating the movement of the arrow on the scale. Therefore, low-power transistors can be applied to the energy consumption of minimal and in this scheme. The rest of the scheme does not differ from those discussed earlier.

The threshold diodes VD1 ... VD6 are designed to reliably disconnect non-working LEDs, so if there is a weak illumination of unnecessary segments, it is necessary to use diodes with a large direct voltage or turn on two diode sequentially. The "cloning" of the cells reduces the brightness of the upper luminescence according to the segment scheme, to remove this instead of the R9 resistor, you need to enter the current generator. And we agreed - do not complicate. Therefore, in this case, 8 cells are maximum.

Fig. 7.

Food Indicators that consume a current of less than 150 ... 200 mA It is quite possible to feed from the Remote of the head device. The voltage there is 0.5 ... 1 to less than in the on-board network, but this will not affect the device. If the current consumed by the indicator is greater, you will have to use a low-power relay (RES-55, RES-10) or collect electronic relay According to Scheme Fig.8.

And if it came about food, it would be nice to supply the audio system with its own voltmeter. Even if it is in the regular equipment of the car, when the ignition is turned off, it does not work. In addition, the voltage is measured in some unknown point. In domestic cars, it affects decisively all - from the included "turn signals" to the blinking light bulb of the handbrake. For our purposes, it is better to measure the voltage on the terminals of the battery or on the buffer condenser - where it is more convenient.

A simple arrow voltmeter is not suitable - it has a linear scale, and all that below 10-11 volts we are not interested. The decent head unit is blocked or "freezes" if the voltage in the onboard network is lowered to these limits. Therefore, the scale must be stretched so that it resembles the scale of the usual automotive voltmeter on the instrument panel. By the way, the "ordinary car" can be used for this purpose, but not worth it. It consumes a decent current from the onboard network (several tens of milliampers), why and is included through the ignition lock. And we need a voltmeter working constantly or at least regardless of ignition. The scheme of such a voltmeter is shown in Fig. nine.

Stabilization stabilization stabilization voltage of about 10.5 ... 11 V provides a "stretching" scale, a voltmeter resistor is calibrated to a maximum deviation at maximum voltage in the onboard network (14.5-16 V). The scale will have to build by points using an adjustable power supply and a reference voltmeter. If accurate values \u200b\u200bare not required, it can be limited only to the definition of the borders of the "green" and "red" sector. Current consumed is determined by the current of the deflection of the indicator (less than a milliamper), so the voltmeter can be done in an untouched - the clock consumes much more.

For LED power indicator, the power will be more suitable next scheme (Fig.10).

The principle of its action is the same as the previous one. While the voltage in the on-board network is normal, the transistor is open and shunt the LED. As soon as the voltage decreases to stabilization stabilization stabilization, the transistor closes and the LED will flash, signaling about the problem. For better notice, you can use the "flashing" LED with a built-in control circuit. The trigger threshold is determined by Stabitron, so it will have to be selected for the accurate tuning. In contrast to the previous one, this scheme consumes a larger current determined by the R2 resistor. Although he is small (about 10 mA), it is better to feed it from the release of Remote, taking into account the loss of tension on it.

Design When debugging structures, you can use trimming resistors, but you should not transfer them to the finished scheme - reliability may suffer, especially when using small-sized potentiometers open type. It is better to measure the mounted resistance to the digital device and to have a constant resistor of the desired nominal value.

Arrow indicators contain a minimum of parts, so they can be assembled by mounting, gluing the parts to the body of the instrument. The scale can be printed on a color printer (in prehistoric times I had to draw her ink and paint).

LED scales and scoreboard are convenient in operation, but allow you to get only a "line" or "column". If you need a scale of a broken or curvilinear form, it will have to be performed from single LEDs. They need to be glued into the front (carrier) indicator panel, close the printed scale with holes on top of it, and on top of it - a thin plexiglass. To fix the LEDs, you can use a dense landing or glue.

For LED indicators, it is better to use installation on the board - a lot of parts. It makes sense to make a full-fledged printed circuit board for the sake of experience, therefore it is easier to use for the installation of details of the industrial manufacturing board. It is placed on it, and the connections are made by a thin mounting wire. In the extreme case, you can place parts on a sheet of fine textolite or cardboard, climbing outlets on the opposite direction and connect them according to the diagram using both the findings and the mounting wire. The circuit board can be combined into one with the LED panel. Finished scheme After tuning, rinse from the remnants of the flux to the alcohol mixture (take care of the plastic parts of the indicator!) And to cover varnish to protect against oxidation. If you wish, you can even pour everything in the "Cube" from epoxy resin ...

And finally. The indicator is not a power meter, but only a pointer. Therefore, it must be treated with caution, although the scale can be calibrated.

Published in the magazine "Master 12 Volt" number 32 (April 2001) I propose for a repetition principal scheme Sound light indicator. The scheme is performed on the Soviet chip K157D1. The device is made for a two-channel power amplifier.Meals are single-polar - 9 volts, and performed on simple stabilizer The voltage made on the 78L09 chip - it is shown in the diagram.

The device connects to the output of the power amplifier, although its sensitivity is quite sufficient and to remove the sound from linear input.

The device setting is performed by variable resistors of 30K and C7 and C8 condensers. The position of the arrow is removed by variable resistors at maximum power, and condensers - the reverse time time of the arrows.

This arrow indicator is assembled on pCBwhich is fixed on the housing of the indicator heads.

The indicator heads were taken from the old Soviet tape recorder. Almost any beautiful shooters with a current of complete deviation of 50-200 mk will fit here. If desired, how fashionable it is now, you can make a blue or green lED backlight Scale. Article author: M. Peleh

I remember a carefree childhood - visiting a classmate listening to music. Amplifier "Radio engineering-001-stereo", indicators gently pegs in tact of music ... Then it was the limit of dreams. Both blaspheme seemed when the father of a classmate (a man was fond of radio amateur) replaced the regular shooting indicators on a luminescent gadko-green. And the amplifier lost part of the charm, and no longer wanted to listen ...

I want a shooter!

And many years have passed. And so I slowly (sometimes it seems that too slowly) collect an amplifier on the lamps. And everyone has long been clear that the level indicator on the amplifier is a bun. Especially now, when the channels in the source almost never differ in terms of the level, and the concept of "stereo balance" has sunk in the summer. And nevertheless - I want a shooter "show meter" to the front panel, and that's it! Ascetic design, with yellow illumination.Since the indicator-show meter is not an important part of the amplifier (no effect on speed and stability), then its construction has been done on the sounding unit. The head of the indicator itself was chosen and purchased for a long time:

I managed to find dual, with a yellowish panel. The backlight from the manufacturer was made by a coaxial incandescent bulgarization by 12 volts. Which was successfully replaced by 4 yellow LEDs. But it happened later.

In the meantime, it was necessary to think about how micro-versions connect to the output of the amplifier? And it is necessary to connect through a special logarithmic amplifier, since the dynamic sound range is much larger than the range of the micronometra operation. Theoretically, everyone knows who came across homemade arrow indicators.

Deadanium of antiquity deep ... K157Da1

In the USSR, a special chip was released for this - K157D1.. The microcircuit has no analogues abroad. Connection diagram is simple, even on the datashet and you need a bipolar meal (inconvenient). But the microcircuit is successfully working and from single-polar nutrition. Moreover, the use of transistors instead of diodes in the scheme allows you to expand the range of shown values \u200b\u200bof up to 40 dB:

Different variations of this scheme in the network Pond Pond. Well, what to say ... she did not go with me.

The first copy is safely burned out of the wrong feed. During the month, I got two more things, but it was already too late, I switched to another scheme (on LM324), kindly provided to me Alexd.. For the sake of interest, then I still turned on the fee with Da1. I did not like it, the smooth movement was not observed. The modification of the scheme was made in close cooperation with Alexey, for which again "Danke Sean"!

Numero Due - LM324

Then there was a mentioned version on LM324. But I did not work for me as I want. The talk of the arrows, it must be selected by the depth of the OS. Yes, and in fact, the food is necessary a bipolar, maybe everything is due to an incorrectly organized midpoint. No, Lena was born before me. And together with laziness, we gave birth that:

Century xxi, attyny13

It's easy and tasteful: straighten and smoothing the signal, then apply it to the microcontroller ADC. We proceed programmatically and with the help of the built-in PWM Issue for a load (resistor). Processing includes practically only natural logarithming (Attyny13 directly as designed for such simple tasks, well, so that the firmware can be baked on an ambulance hand).

And then the most interesting thing starts for me. The function of natural logarithm is in the library mathematical functions For ATMEL controllers and is in the Math.h file. But it just does not climb into this controller - memory is not enough. It is not possible to solve the task in the forehead, we begin to smell it (forehead). The use of a more powerful controller was not considered - not interesting. There is also enough memory, and it is convenient, and inexpensive, and the dimensions are not big. The first thing that occurred to is to replace this feature similar, but easier. And the shape of her to leisure the coefficients. Remember the reverse function schedule. Not "yes well!", I remember! If the lower right square is shifted up with respect to the X axis, and slightly pull out the coefficients, then it is quite possible to fit under the desired form. Here it is, the formula that replaces the logarithm: Y \u003d -8196 / (X + 28) +284. Certain the horror of the controller, doomed to calculate these values \u200b\u200bthousands of times per second on the whims of the owner who wished to remember the "golden childhood"?

But unpleasant emotions were guaranteed and the owner of the controller. There were few short integer values \u200b\u200bfor processing results, and the input and output should be exactly the same. For me, the transfer of data presentation formats in the controllers of one to another has always been difficult. Wrinkles on the forehead multiplied.

Born the second option - Clean everything in advance, and the controller will simply leave the data from the array that correspond to the input values \u200b\u200band throw them out. We prepare the values \u200b\u200bset by the array - the compilation error. The dimension of the array is too large for this controller. And do a few arrays and climb into them depending on the input value of the ADC is not kosher. Thought about Binin Newton, but were rejected because of non-constructiveness.

Here in the memory of the phrase of the lecturer at the highest mathematics from the university surfaced: "With the help of cubic spline approximation, you can describe any function" Well, we do not need cubic, and the linear spline will fully go! Thus, I understated a little in OO Calc, and wrote a system of equations, a fairly precisely repeating graph of a logarithmic function using straight lines:

if (n\u003e \u003d 141) x \u003d 2 * n + 2020; ELSE if (n\u003e \u003d 66) x \u003d 5 * n + 1600; ELSE if (n\u003e \u003d 38) x \u003d 9 * n + 1330; ELSE if (n\u003e \u003d 21) x \u003d 15 * n + 1110; ELSE if (n\u003e \u003d 5) x \u003d 40 * n + 600; ELSE if (n\u003e 0) x \u003d 160 * n + 50; if (n \u003d\u003d 0) x \u003d 0;

Everything is deliberately multiplied by 10 so that the discarded "tails" were smaller. I then share it in the program before the output to the indicators.

But graphics:

I am sure that many of you such a decision will come to mind immediately and seems obvious. Nevertheless, I am sure that someone is entering for someone and later come in handy. At least, as a tool in its arsenal will not be superfluous.

Video

Results and notes according to the scheme

The indicator-shown meter has earned perfectly from the first inclusion. A few firmware were filled. The most simple turned out to be the most successful.According to the scheme: CONDENSERS C1 and C2 during the setup process were replaced by 10.0 μF - they provide smoothness. Strip resistors at the input reduce the maximum signal up to 5 volts. Theoretically, it would be necessary to put a stabilion with a resistor, but lazy ... Well, you already know who of us was born before: Laughing: I loaded the amplifier to the maximum signal from my point of view (so that the equivalents at the exit ran), and brought the resistors to 5 Volt. I am enough. Then he filed 1 kHz input from the generator and synchronized the channels, slightly reducing the readings of one of the microammeters. R4 and R5 depend on the total current deviation of microammeters, the diagram is indicated for 50 μA, I have such.

The scheme can be tuning.Tinki remained free 2 legs. No one prevents the LEDs to adjust the LEDs to indicate the overload, sometime it was fashionable. Not mine - I do not like, when something on the amplifier blinks, therefore did not do. Implementation of the elementary: at a certain level, we light the LED and keep the burning N Miliseconds. Level and n are chosen to taste like salt and pepper. Do not forget only that one of the free legs is RESET. And therefore, do the experiments on one channel, for if you put the appropriate fusion during the firmware, the reset will become just a port, and the controller will fail after that.

Files

And files: Project in CVAVR, firmware, scheme in the alloy.We do not bring the seal, it is without necessary: \u200b\u200bthe likelihood that someone will have such a micro ammeter and will need to attach the controller seeks to zero. Yes, and looking at the scheme, you can imagine what simple fee

▼ 🕗 24/09/12 ⚖️ 55,23 Kb ⇣ 431 Hello, reader! My name is Igor, I'm 45, I am a Siberian and an avid email. I invented, created and contain this wonderful site since 2006.

For more than 10 years, our magazine exists only to my funds.

Good! Halyava ended. You want files and useful articles - help me!

Magnetometry in the simplest version The ferrozond consists of a ferromagnetic core and two coils on it

Magnetometry in the simplest version The ferrozond consists of a ferromagnetic core and two coils on it Effective job search course search

Effective job search course search The main characteristics and parameters of the photodiode

The main characteristics and parameters of the photodiode How to edit PDF (five applications to change PDF files) How to delete individual pages from PDF

How to edit PDF (five applications to change PDF files) How to delete individual pages from PDF Why the fired program window is long unfolded?

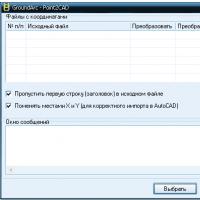

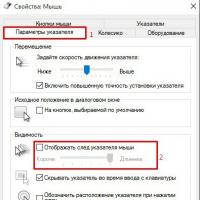

Why the fired program window is long unfolded? DXF2TXT - export and translation of the text from AutoCAD to display a dwg traffic point in TXT

DXF2TXT - export and translation of the text from AutoCAD to display a dwg traffic point in TXT What to do if the mouse cursor disappears

What to do if the mouse cursor disappears