Charger for Lipo. Charger for lithium polymer (lipo) batteries. What is afraid lipo.

Assessment of the characteristics of a charger is difficult without understanding how the exemplary charge should act. li-ion batterybut. Therefore, before proceeding directly to the schemes, let's remember the theory a little.

What are lithium batteries

Depending on what material is made of a positive electrode lithium batteryThere are several varieties of them:

- with cobeda of cobaltat lithium;

- with cathode based on lithium iron phosphate;

- based on nickel-cobalt aluminum;

- based on nickel-cobalt-manganese.

All these batteries have their own characteristics, but since for a wide consumer, these nuances have no fundamental importance, in this article they will not be considered.

All Li-Ion batteries are also produced in various sizes and form factors. They can be both in a housing design (for example, 18650 popular today) and in laminated or prismatic design (gel polymer batteries). The latter are hermetically sealed packages made of special films in which electrodes and electrode mass are located.

The most common sizes of Li-Ion batteries are shown in the table below (they all have a rated voltage of 3.7 volts):

| Designation | Size | Similar sizes |

|---|---|---|

| Xxyy0., Where XX - indication of the diameter in mm, Yy - value of length in mm, 0 - reflects the execution in the form of a cylinder |

10180 | 2/5 AAA |

| 10220 | 1/2 AAA (Ø corresponds to AAA, but half of the length) | |

| 10280 | ||

| 10430 | AAA | |

| 10440 | AAA | |

| 14250 | 1/2 AA | |

| 14270 | Ø AA, length CR2 | |

| 14430 | Ø 14 mm (like AA), but length is less | |

| 14500 | AA | |

| 14670 | ||

| 15266, 15270 | CR2. | |

| 16340 | CR123. | |

| 17500 | 150s / 300s. | |

| 17670 | 2xCr123 (or 168S / 600S) | |

| 18350 | ||

| 18490 | ||

| 18500 | 2xcr123 (or 150a / 300p) | |

| 18650 | 2xcr123 (or 168a / 600p) | |

| 18700 | ||

| 22650 | ||

| 25500 | ||

| 26500 | FROM | |

| 26650 | ||

| 32650 | ||

| 33600 | D. | |

| 42120 |

Internal electrochemical processes proceed equally and do not depend on the form factor and the execution of the AKB, so everything that has been said is equally applied to all lithium batteries.

How to charge lithium-ion batteries

Most right way The charge of lithium batteries is charged in two stages. This method uses Sony in all its chargers. Despite the more complex charge controller, it provides a more complete charge of Li-Ion batteries, without reducing their service life.

Here we are talking About the two-stage charge profile of lithium batteries, shortcutly called CC / CV (Constant Current, Constant Voltage). There are still options with hypertices and speed currents, but in this article they are not considered. Read more about charging pulse current you can read.

So, consider both stages of charge.

1. At the first stage A constant charge current must be provided. The value of the current is 0.2-0.5c. For an accelerated charge, an increase in current is allowed to 0.5-1.0 ° C (where C is the battery capacity).

For example, for a battery with a capacity of 3000 m / h, the rated charge current at the first stage is 600-1500 mA, and the current charge current may lie within 1.5-3A.

To ensure permanent charging current of a given value, the charger diagram (memory) should be able to raise the voltage on the battery terminals. In fact, at the first stage, it works as a classic current stabilizer.

Important: If you plan batteries with an integrated protection board (PCB), then when designing a memory circuit, you must make sure that the idling stroke voltage will never be able to exceed 6-7 volts. Otherwise, the protection board may fail.

At a time when the voltage on the battery rises to the value of 4.2 volts, the battery drops approximately 70-80% of its capacitance (the specific value of the capacity will depend on the charge current: with an accelerated charge it will be slightly smaller, at a nominal one - a little more). This moment is the end of the first stage of the charge and serves as a signal to move to the second (and last) stage.

2. The second stage of charge - This is the battery charge constant tensionBut gradually declining (falling) current.

At this stage, the voltage 4.15-4.25 voltage maintains on the battery and controls the current value.

As the tank set, the charging current will decrease. As soon as its value decreases to 0.05-0.01С, the charge process is considered to be completed.

An important nuance of the proper charger is its full shutdown From the battery after the end of charging. This is due to the fact that for lithium batteries is extremely undesirable to their long-term detection under increased voltage, which usually provides memory (i.e. 4.18-4.24 volts). This leads to accelerated degradation of the chemical composition of the battery and, as a result, reducing its capacity. Under long finding is meant tens of hours or more.

During the second stage of charge, the battery has time to score more than about 0.1-0.15 of its capacitance. The overall charge of the battery thus reaches 90-95%, which is an excellent indicator.

We looked at the two main stages of charge. However, the coverage of the charge of lithium batteries would be incomplete if another charge stage was not mentioned - so-called. Prepare.

Preliminary Charge Stage (Prepare) - This stage is used only for deeply discharged batteries (below 2.5 V) to output them to normal operational mode.

At this stage, the charge is ensured dC reduced values \u200b\u200buntil the voltage on the battery reaches 2.8 V.

The preliminary stage is necessary to prevent intimidation and depressurization (or even an explosion with fire) damaged batteries having, for example, internal short circuit between the electrodes. If through such a battery immediately skip a high charge current, it will inevitably lead to healing it, and then how lucky.

Another benefit of the prerequisite is preliminary battery warming, which is relevant when charging at low temperatures. ambient (In the unheated room in the cold season).

Intelligent charging should be able to control the voltage on the battery during the preliminary charge stage and, in case the voltage for a long time Does not rise, make an output of the battery malfunction.

All stages of charge lithium-ion battery (including the prerequisite stage) are schematically depicted on this schedule:

Excess of the nominal charging voltage by 0.15V can reduce battery life twice. A decrease in the charge voltage by 0.1 volts reduces the capacity of the charged battery by about 10%, but significantly extends its service life. The voltage of the fully charged battery after removing it from the charger is 4.1-4.15 volts.

Summarize the above, we denote the basic theses:

1. What is the current to charge the Li-Ion battery (for example, 18650 or any other)?

The current will depend on how quickly you would like to charge it and can lie in the range from 0.2c to 1C.

For example, for a battery size of 18650 with a capacity of 3400 mA / h, the minimum charge current is 680 mA, and the maximum - 3400 mA.

2. How much time needs to be charged, for example, the same rechargeable batteries 18650?

The charge time directly depends on the charge current and is calculated by the formula:

T \u003d C / I ZA.

For example, the charge time of our accumulator with a capacity of 3400 mA / h current in 1a will be about 3.5 hours.

3. How to charge a lithium-polymer battery correctly?

Any lithium batteries charge the same. It does not matter, lithium-polymer he or lithium-ion. For us, consumers, there is no difference.

What is the protection board?

Protection board (or PCB - POWER CONTROL Board) is designed to protect against short circuit, reloading and redevelopment of lithium battery. As a rule, overheating protection is also built into the protection modules.

In order to comply with safety, the use of lithium batteries in household appliances is prohibited if the protection fee is not built into them. Therefore, in all batteries from cell phones there is always a PCB fee. Output terminals of the battery are placed right on the board:

These boards use a six-legged charge controller on a specialized microme (JW01, JW11, K091, G2J, G3J, S8210, S8261, NE57600, etc. Analogs). The task of this controller is to disconnect the battery from the load when the battery is fully discharged and shutting down the battery from charging upon reaching 4.25V.

Here, for example, a BP-6M battery protection circuit, which supplied old Nokiev phone phones:

If we talk about 18650, they can be released as a protection fee so without it. The protection module is located in the area of \u200b\u200bthe minus battery terminal.

The board increases the battery length by 2-3 mm.

Batteries without a PCB module are usually included in batteries completed with their own protection schemes.

Any battery with protection is easily turning into a battery without protection, just just jump it.

To date maximum capacity The accumulator 18650 is 3400 mA / h. Batteries with protection necessarily have a corresponding designation on the housing ("Protected").

Do not confuse PCB fee with PCM module (PCM - Power Charge Module). If the first serve only the targets for protecting the battery, then the second are designed to control the charge process - limit the charge current at a given level, control the temperature and, in general, ensure the entire process. The PCM board is what we call the charge controller.

I hope now there are no questions left, how to charge a 18650 battery or any other lithium? Then go to a small selection ready-made schemessubsidiary solutions of chargers (those most charge controllers).

Battery Li-Ion Charge Schemes

All schemes are suitable for charging any lithium battery, it remains only to determine the charging current and an element base.

LM317.

Scheme of a simple charger based on the LM317 chip with charge indicator:

The simplest scheme, the entire setting is reduced to the installation of the output voltage of 4.2 volts using the R8 stroke resistor (without a connected battery!) And the charge current installation by selecting resistors R4, R6. The power of the resistor R1 is at least 1 watt.

As soon as the LED goes out, the charge process can be finished (the charging current to zero will never decrease). It is not recommended to keep the battery in this charging for a long time after it is fully charged.

The LM317 microcircuit is widely used in various voltage and current stabilizers (depending on the inclusion circuit). Sold on every corner and stands at all a penny (you can take 10 pcs. Total for only 55 rubles).

LM317 happens in different buildings:

Purpose of conclusions (Cocolevka):

Analogues of the LM317 chip are: GL317, SG31, SG317, UC317T, ECG1900, LM31MDT, SP900, KR142EN12, KR1157EN1 (last two - domestic production).

Charging current can be increased to 3A if instead of LM317 take LM350. She, however, will be more expensive - 11 rubles / pcs.

The printed circuit board and the collection scheme are shown below:

The old Soviet transistor Kt361 can be replaced by a similar p-N-P transistor (for example, CT3107, CT3108 or Bourgeois 2N5086, 2SA733, BC308A). It can be removed at all if the charge indicator is not needed.

Lack of scheme: supply voltage must be within 8-12V. This is due to the fact that for normal operation of the LM317 chip, the difference between the battery voltage and the supply voltage should be at least 4.25 volts. Thus, the USB port will not be powered.

MAX1555 or MAX1551

MAX1551 / MAX1555 - specialized chargers for Li + batteries that can work from USB or from a separate power adapter (for example, a charger from the phone).

The only difference between these chips - max1555 gives a signal for the charge indicator, and MAX1551 is the signal that power is enabled. Those. 1555 In most cases, it is still preferable, so 1551 is already difficult to find on sale.

The only difference between these chips - max1555 gives a signal for the charge indicator, and MAX1551 is the signal that power is enabled. Those. 1555 In most cases, it is still preferable, so 1551 is already difficult to find on sale.

Detailed description of these chips from the manufacturer.

The maximum input voltage from the DC adapter is 7 V, when powered by USB - 6 V. When a supply voltage is reduced to 3.52 V, the chip is disconnected and the charge stops.

The microcircuit itself detects at what input is the supply voltage and connects to it. If the power goes according to the USB bus, the maximum charge current is limited to 100 mA - it allows you to push the charger to the USB port of any computer without fear of burning the southern bridge.

When powered from a separate power supply, the typical value of the charging current is 280 mA.

In the microcircuits are built-in overheating protection. But even in this case, the scheme continues to operate, reducing the charge current by 17 mA per degree above 110 ° C.

There is a pre-charge function (see above): until the voltage on the battery is below 3V, the chip limits the charge current at 40 mA.

The microcircuit has 5 conclusions. Here is a typical inclusion scheme:

If there is a guarantee that at the output of your adapter, the voltage must not be able to exceed 7 volts, then you can do without a 7805 stabilizer.

USB charging option can be collected, for example, on such.

The chip does not need external diodes, nor in external transistors. In general, of course, gorgeous microhi! Only they are small too, to solder uncomfortable. And still cost ().

LP2951.

The LP2951 stabilizer is made by National Semiconductors (). It provides the implementation of the built-in current limit function and allows you to form a stable level of charge voltage level of a lithium-ion battery at the output scheme.

The value of the charge voltage is 4.08 - 4.26 volts and is set to the R3 resistor when the battery is disconnected. Voltage is very accurate.

The charge current is 150 - 300mA, this value is limited by the internal circuits of the LP2951 chip (depends on the manufacturer).

Diode apply with low reverse current. For example, it can be any of the 1N400X series, which will be able to purchase. The diode is used as blocking, to prevent the return current from the battery in the LP2951 chip when the input voltage is disconnected.

This charging gives a rather low charging current, so that any battery 18650 can charge all night.

The chip can be bought both in the DIP-housing and in the SOIC housing (cost of about 10 rubles for the face).

MCP73831

The chip allows you to create the right chargers, besides it is cheaper than the promoted MAX1555.

Typical inclusion scheme taken from:

An important advantage of the scheme is the absence of low-level powerful resistors that limit the charge current. Here the current is set by the resistor connected to the 5th conclusion of the chip. Its resistance must lie in the range of 2-10 com.

Charging assembly looks like this:

The microcircuit in the process of work is well heated so much, but it does not seem to her. Performs your function.

Here is another option pCB from sMD LED and micro-USB connector:

LTC4054 (STC4054)

Highly simple scheme, excellent option! Allows you to charge up to 800 mA (see). True, it has a property very much, but in this case the built-in overheating protection reduces the current.

You can easily simplify the scheme by throwing out one or even both LEDs with a transistor. Then she will look like this (you see, it's easier to nowhere: a pair of resistors and one Conder):

One of the printed circuit board options is available by software. The board is calculated under the elements of the size of 0805.

I \u003d 1000 / R. Immediately a large current is not worth it, first look at how much the microcircuit will be warm. I took the resistor for my goals at 2.7 com, while the charge current turned out about 360 mA.

The radiator to this chip is unlikely to be able to adapt, and not the fact that it will be effective due to the high thermal resistance of the transition of the crystal-housing. The manufacturer recommends making the heat sink "through the conclusions" - to make as thick paths as possible and leave the foil under the chip body. And in general, the more "earth" foil will be left, the better.

By the way, most of the heat is given through the 3rd leg, so you can make this track very wide and thick (pour it with an overpressure of solder).

The LTC4054 chip body may have LTH7 or Ltady marking.

LTH7 from Ltady is distinguished by the fact that the first can raise a strongly sitting battery (on which the voltage is less than 2.9 volts), and the second - no (you need to split separately).

The chip came out very successful, so it has a bunch of analogues: STC4054, MCP73831, TB4054, QX4054, TP4054, SGM4054, ACE4054, LP4054, U4054, BL4054, WPM4054, IT4504, Y1880, PT6102, PT6181, VS6102, HX6001, LC6000, LN5060, CX9058, EC49016, CYT5026, Q7051. Before using any of the analogues, check on datasheets.

TP4056.

The microcircuit is made in the SOP-8 case (see), has a metal heat generator on a belly, which allows you to more effectively remove heat. Allows you to charge the battery to 1a (depends on the current resistor).

The connection scheme requires the minimum of attachments:

The scheme implements the classic charge process - first the charge of a constant current, then a constant voltage and a falling current. Everything is scientifically. If you disassemble charging in steps, you can select several stages:

- Control of the voltage of the connected battery (this happens constantly).

- Prerequisite phase (if the battery is discharged below 2.9 V). 1/10 charge from the R PROG programmed by the resistor (100ma at R Prog \u003d 1.2 com) to 2.9 V.

- Charging with the maximum current of a constant value (1000mA at R Prog \u003d 1.2 com);

- When it is reached on the battery 4.2 V, the battery voltage is fixed at this level. The smooth decrease in the charging current begins.

- When the current 1/10 is reached from the R PROG programmed by the resistor (100ma at R Prog \u003d 1.2kom), the charger is turned off.

- After the charging is completed, the controller continues to monitor the battery voltage (see clause 1). Current consumed by a monitoring scheme 2-3 μA. After the voltage drop to 4.0V, the charging is turned on again. And so in a circle.

Charge current (in amperes) is calculated by the formula I \u003d 1200 / R Prog. The maximum permissible is 1000 mA.

The real charge charge with a battery 18650 by 3400 mA / h is shown in the graph:

The advantage of the chip is that the charge current is given by only one resistor. Most powerful low-level resistors are required. Plus there is an indicator of the charge process, as well as an indication of the end of charging. With an unscheduled battery, the indicator blinks with a frequency once a few seconds.

The supply voltage of the diagram must lie within 4.5 ... 8 volts. The closer to 4.5V, the better (so the chip is heated less).

The first foot is used to connect the temperature sensor built into the lithium-ion battery (usually this average battery output. cell phone). If the voltage output is below 45% or above 80% of the supply voltage, the charging is suspended. If you do not need control control, just put this leg to the ground.

Attention! This scheme has one significant disadvantage: the lack of a battery reversal protection scheme. In this case, the controller is guaranteed to focus due to exceeding the maximum current. At the same time, the supply voltage of the circuit directly falls on the battery, which is very dangerous.

Printing is simple, it is done per hour on the knee. If the time is tolerate, you can order ready-made modules. Some manufacturers finished modules Add protection against current overload and overloading (, for example, you can choose which card you need - with or without protection, and with what connector).

You can also find ready-made boards with an derived contact for the temperature sensor. Or even a charging module with several TP4056 chicircles for increasing the charging current and with a stir protection (example).

LTC1734.

Also a very simple scheme. The charge current is set by the R PROG resistor (for example, if you put a resistor by 3 kΩ, the current will be 500 mA).

Chips usually have labeling on the housing: ltrg (they can often be found in old phones from Samsung).

The transistor is suitable at all any P-N-PThe main thing is that it is designed for a given charging current.

The charge indicator on the specified scheme is not, but in LTC1734 it is said that the output "4" (PROG) has two functions - the current installation and control of the battery charge. The example shows a scheme with charge end control using the LT1716 comparator.

The LT1716 comparator in this case can be replaced by cheap LM358.

TL431 + transistor

Probably it is difficult to come up with a scheme from more affordable components. It is the most difficult thing here is to find the TL431 reference voltage source. But they are so common that they are found almost everywhere (rarely, as a source of nutrition costs without this chip).

Well, the TIP41 transistor can be replaced with any other with a suitable collector current. Even old Soviet CT819, CT805 (or less powerful KT815, KT817) are suitable.

The scheme setting is reduced to the output voltage setting (without battery !!!) using a stroke resistor at 4.2 volts. Resistor R1 sets the maximum charging current value.

This scheme fully implements a two-step process of charge lithium batteries - first charging a direct current, then the transition to the voltage stabilization phase and the smooth decrease in the current almost to zero. The only drawback is the poor repeatability of the circuit (the caprication in the setting and demanding to the components used).

MCP73812.

There is one more undeservedly deprived of the microcircuit from Microchip - MCP73812 (see). At its base it turns out very a budget option Charging (and inexpensive!). All body kit is just one resistor!

By the way, the chip is performed in a package convenient for soldering - SOT23-5.

The only minus is greatly heated and there is no charge indication. She is still somehow working very well if you have a low-power supply source (which gives stress drawdown).

In general, if the charge indication is not important for you, and the current of 500 mA suits you, then the MSR73812 is a very good option.

NCP1835

A fully integrated solution is proposed - NCP1835B, providing high stability of the charging voltage (4.2 ± 0.05 V).

Perhaps the only disadvantage of this chip is its too miniature size (DFN-10 case, size 3x3 mm). Not everyone can provide high-quality soldering of such miniature elements.

From indisputable benefits I would like to note the following:

- The minimum number of body parts.

- The possibility of charging a fully discharged battery (overhead of the current of 30mA);

- Determining the end of charging.

- Programmable charging current - up to 1000 mA.

- Indication of charge and errors (able to detect unloadable batteries and signal it).

- Protection against a long charge (changing the capacitor capacitor with T, you can set the maximum charge time from 6.6 to 784 minutes).

The cost of the chip is not so kopeck, but not so big (~ $ 1) to abandon its use. If you are friends with a soldering iron, I would recommend to stop your choice on this option.

More detailed description located in .

Is it possible to charge a lithium-ion battery without a controller?

Yes, you can. However, this will require tight control of the charging current and voltage.

In general, to charge the battery, for example, our 18650 will not work at all without a charger. All the same, it is necessary to somehow limit the maximum charge current, so at least the most primitive memory, but still it will be necessary.

The simplest charger for any lithium battery is a resistor enabled sequentially with the battery:

The resistance and power of the scattering of the resistor depend on the power supply voltage to be used for charging.

Let's calculate the resistor for the power supply of 5 volts. We will charge the 18650 battery, with a capacity of 2400 mA / h.

So at the very beginning of charging drop voltage on the resistor will be:

U r \u003d 5 - 2.8 \u003d 2.2 volts

Suppose our 5-volt power supply is calculated for maximum current 1a. The biggest current scheme will consume at the very beginning of the charge, when the voltage on the battery is minimal and is 2.7-2.8 volts.

ATTENTION: These calculations are not taken into account the likelihood that the battery can be very deeply discharged and the voltage on it can be much lower, right up to zero.

Thus, the resistance of the resistor necessary to limit the current at the very beginning of the charge at the level of 1 amp should be:

R \u003d u / i \u003d 2.2 / 1 \u003d 2.2 ohms

Resistor dispersion capacity:

P r \u003d i 2 r \u003d 1 * 1 * 2.2 \u003d 2.2 W

At the very end of the battery charge, when the voltage on it approaches 4.2 V, the charge current will be:

I \u003d (U IP - 4.2) / R \u003d (5 - 4.2) / 2.2 \u003d 0.3 A

Those., As we see, all values \u200b\u200bdo not go beyond permissible for this battery: the initial current does not exceed the maximum allowable charge current for a given battery (2.4 a), and the final current exceeds the current at which the battery is already stopped recruiting the container ( 0.24 a).

The most important drawback of such charging is to constantly monitor the voltage on the battery. And manually disable the charge as soon as the voltage reaches 4.2 volts. The fact is that lithium batteries are very poorly carrying even short-term overvoltage - the electrode masses begin to degrade rapidly, which inevitably leads to loss of tank. At the same time, all prerequisites for overheating and depressurization are created.

If the protection fee is built into your battery, about which it was slightly higher, then everything is simplified. Upon reaching a certain battery voltage, the board itself turns it off from the charger. However, this method of charging has the essential minuses that we told in.

Protection embedded in the battery will not allow it to recharge under any circumstances. All you have to do is to control the charge current so that it does not exceed the permissible values \u200b\u200bfor this battery (the protection fees do not know how to limit the charge current, unfortunately).

Charging with the Laboratory Power Supply

If your disposal has a power supply with protection (restriction) by current, then you are saved! Such a power source is already a full-fledged charger that implements the correct charge profile, which we wrote above (CC / CV).

All you need to do for charging Li-Ion - It is 4.2 volts on the power supply 4.2 volt and set the desired current limit. And you can connect the battery.

All you need to do for charging Li-Ion - It is 4.2 volts on the power supply 4.2 volt and set the desired current limit. And you can connect the battery.

First, when the battery is still discharged, laboratory block Power will work in current protection mode (i.e., it will stabilize the output current at a given level). Then, when the tension on the bank rises to the 4.2V installed, the power supply will switch to the voltage stabilization mode, and the current will start falling.

When the current falls to 0.05-0.1c, the battery can be fully charged.

As you can see, laboratory BP is a practically perfect charger! The only thing he does not know how to do automatically, is to decide on complete charge Battery and disconnect. But this is a trifle, which is not even worth paying attention.

How to charge lithium batteries?

And if we are talking about a disposable battery that is not intended for recharging, the correct (and the only right) answer to this question is in any way.

The fact is that any lithium battery (for example, the common CR2032 in the form of a flat tablet) is characterized by the presence of an internal passivating layer, which is covered with a lithium anode. This layer prevents the chemical reaction of an anode with an electrolyte. A third-party feed destroys the above protective layer, leading to a damage of the battery.

By the way, if we talk about an unloadable CR2032 battery, that is, the LIR2032 very similar to it is already a full battery. Its can be charged. Only she does not voltage 3, but 3.6V.

About the same way to charge lithium batteries (whether there is a phone battery, 18650 or any other Li-Ion battery) was discussed at the beginning of the article.

@@ idea to collect anything with your own hands for the model store is not alien, you can even say the relatives. But when it comes to electronics, it is often ordinary (especially a beginner) modelist lowers / raises his hands from seemingly hopeless position of sensitive cash costs. These fears are no exception and for those who think to go to lipo batteries.

@@ Charger per an acceptable price Does not guarantee safe charging. On the expensive charger immediately somehow sorry for money. Moreover, when you read in forums about professional "smart" chargers, which also do not always agree with the user requirements.

@@ and for a beginner model of thought about the budget often widespread over the reasonable conclusion that " free cheese There is only a mousetrap. "For this reason, as well as the desire to burn your fingers with a soldering iron, pushed me to the development of your own, moderately" smart "charger.

@@ searches on the Internet ready-made schemes showed that they are quite a lot. However, finding a simple, moderately smart, failed. But then I finally decided: collect yourself. Scriming the information on charging Lipo, began for iron. I don't have any special knowledge in electronics, so it's not to develop the scheme from scratch. As a basis was taken by "Note Applicane" from AVR.

@@ Now you need to decide with the capabilities of the charger. Free-time is extremely small, so immediately limited the function of the charger. Plus simple mat. Calculations summed up to the following:

Microcontroller attiny26.

The choice of this controller was not accidental. He had a fast Shim-125Khz, which simplified the scheme. Well, resources are a decidant in a bail - to implement the task. Oh yeah ... and price.

Power 10-12 volts (for recharging in the field)

At first hesitated, and where to take more than 12 volts required for charge 3 cans. So far I have not found in my honeystone 12-\u003e 24 volts converter for the car. The scheme turned out to be so simple that in principle can be repeated and himself. Spere it by 14 volts.

Power - maximum 1.5A - 1-3 Lipo banks (12.6 volts)

Other batteries were not even plans ...

Brains should figure out when stopping the charge and so as not to output the battery (temperature control, time, voltage and current)

Accounting Balancer when charging

I thought first to integrate into the charger, but then I decided to make a separate project - because the motto was: "Be easier!"

Visual control over all that is happening (to know what is happening there in the box).

@@ collected a diagram on the layout. Posted by a test program, connected a resistor ... In general, the work went. 2KB of free memory under the program began to decrease rapidly, which indicated the light at the end of the tunnel.

"" "" Immediately encountered a problem - adjustment of the charge current is not anywhere - jumps within 30%. Many times rewrote the code that is responsible for control and holding the charge current at a given level - it really helped anything. It came ... The problem is not in the program. I remembered the oscilloscope ... So I have pulsations on the shunt resistor under 2 volts by a scope. Something is wrong with the scheme. Pick up the coil and the inclusion frequency - not very helped. But increased the output capacitor from 470mp to 2200mf - everything fell into place. Conclusion: Somewhere in the Atmelian Applicane Note Error. I climbed on the forums - so it is. Well, perhaps it was the biggest problem.

@@ one more problem, but already smaller - it is a measurement measurement. Initially, it seemed to me that this is one of the simplest tasks. The fact is that the thermistor does not change its values \u200b\u200blinearly, but logarithmically. It looks like this:

"" "" This chart and took time, as in the datashet to the resistor there was little information regarding the resistance \u003d temperature. And I needed to get values \u200b\u200bfor each degree. I had to use Excel. So, if someone wishes exact temperature readings for its resistor (which is completely meaningless, since the battery does not die if it will be 42 instead of 40 degrees) can count himself. Next, we make the table of the values \u200b\u200bof the ADC according to the formulas:

@@ V \u003d 5 * (RT / (RT + 1000))where RT - resistance of the resistor at a certain temperature taken from the graph.

@@ ADC \u003d (1024 * V / VREF) / 4where Vref. - Stress on the foot of the 19 microcontroller. There must be 3.7 volts.@@ The resulting ADC value and write to the table in the NTC.INC file. So we do for all temperature values \u200b\u200bfrom 5 to 50 degrees in one degree increments. More special problems are not foreseen, you can draw the seal. I did it in WinQCAD, but in general it is a matter of taste.

@@ I got this option:

"" "" Picture Figure: Facial Side Download Archive (5 KB), Back Side Download Archive (2 KB). As can be seen from the figure, the analog land is separated from the main land and is connected by a resistor of 0 ohms.

"" "" As can be seen from the figure, the analog land is separated from the main land and is connected by a resistor of 0 ohms. The location of the elements on the board is Takovo:

@@ Since the entire manufacturing process is assumed for home conditions, respectively, the fee is also simple. Although she is bilateral, but as seen the second side does not need precision positioning from the first. And holes minimal.

@@ drawing board can be transferred any affordable way (Iron, photoresist, etc.).

Then cerebrusim, drilling holes and conduits through holes imitate metallization of holes. Here is the board and ready - you can attack the rest of the garden.

@@ But before the supay resistors R5, R6, R7, R8, R4, R9 Read the following section.

@@ the configuration process comes down to the following:

1. It is necessary to measure the accurate resistance of the resistors R5 and R6 in parallels;

2. Check the resistance of resistors R7, R8, R4, R9;

INT (ConstVref / 80 * ((resistorpos / resistorgnd) * 128 + 128)), where constvref \u003d 3700 (voltage with TL431 in millivolts), resistorpos \u003d resistance of resistors R7 and R8 in Omah, ResistorGnd \u003d resistance resistors R4 and R9 in Oma ;

4. Using all the same values, we calculate the CONSTIMUL coefficient by the formula:

Constimul \u003d int (ConstVref / ResistorGnd / (Resistorpos + ResistorGnd) * Resistorsht) * 8)

Where plus to the already said resistorsht \u003d resistance resistors R5 and R6 in parallels multiplied by 100 (for example, two resistors in 1 ohm \u003d 0.5 Ohm * 100 \u003d 50);

5. We substitute the obtained coefficients in the Lipocherger.asm file, in the lines:

.equ Constvmul \u003d 22229

.equ constimul \u003d 2416

6. Complete in AvrStudio and fill in the processor;

7. Now on the finished and working board, the variable resistor R14 exhibit a voltage of 3.7 volts to 17 legs of the processor;

8. If you wish, you can experimentally set the exact speed of the processor through OSCCAL. In my case it is 0xa0.

@@ Next - firmware. Conduct a microcontroller standard method (via SPI). Schemes of programmers and all with this associated is not within the competence of this article. The only remark - when programming a microcontroller, it is necessary to turn off the charge voltage - 14 volts (physically disconnect the wire).

@@ With the right installation and compliance with 8 setup items, the charger will start working immediately. The instructions for using the device will not write any hands do not reach, so if someone ever repeat this scheme and write the instructions - I will be very grateful. Although the use of the charger is just funny - only two buttons. There are no hidden "undocumented" features.

@@ Charger Scheme - Download Archive (24 KB)

@@ firmware, program - download archive (35 kb)airsoft guns

IN lately There have been many questions on Lipo batteries. I decided to write an article about charging, the use and selection of Lipo batteries.

For example, consider the Battery Zippy FlightMax 1000mAh 2S1P 20C

All that goes to the figure 1000 is the name of the manufacturer or trademark.

1000mah - This is the battery capacity.

2s1p - 2S This is the number of batteries in the assembly. Each battery has a voltage of about 3.7 volts, so that the voltage of such a battery is 7.4 volts. 1p is the number of assemblies. That is, if you take 2 identical batteries, connect their tape and solder power wires In parallel (plus with a plus, and minus with a minus), then we will receive a doubling of the tank, is indicated by such a 1000 2S2P battery and is actually equal to the operation of 2000 2S1P. Usually use only single assemblies, so 1P does not say and do not write.

20C.- The maximum discharge current is measured in battery tanks.

To calculate how much Lipo will be able to give the amps when the engine is loaded, you must multiply the container to the amount of C and divide by 1000 (since the capacity is specified in the milliamper / clock). The maximum current of this battery will be 20 amperes. For 2200 20c - 44 amps, 1200 30s \u003d 36 amps and so on.

Charging Lipo batteries

Lipo batteries charge 1C current (unless otherwise indicated on the battery itself, recently appeared with the possibility of charging current 2 and 5C). The standard charging current of the battery under consideration 1 amp. For a battery 2200 - there will be 2.2 amperes and TD.

The computerized charger manufactures battery balancing (aligning the voltage at each battery bank) during charging. Although you can charge 2s batteries and without connecting the balancing cable (white connector in the photo) I strongly recommend connect the balancing connector is always! 3S and large builds charge only with a connected straightening wire! If you do not connect and one of the cans drops more than 4.4 volts, then you will be waiting for an unforgettable firework!

You can protect yourself and charge in the special packages - they are not burnt and specifically designed to reduce harm in the case of ignition Lipo batteries.

We continue the story about charging Lipo batteries.

It is usually quickly poured into the battery about 90% of the tank, and then begins to break the balancing of cans. More charged and approached the limit shunt and charge goes to the remaining banks. That is why it can be charged a couple of 3s batteries as one 6s.

The battery is charging up to 4.2 volts to the jar (usually less than a few milvalt less).

"Storage" mode

On the "smart" charger, you can translate Lipo to storage mode, while the battery will disappear / moved to 3.85V to the bank. Fully charged batteries during storage of more than 2 months (maybe less) die. Verified by personal experience. They say that and completely discharged, but for a longer period.

I have stored batteries in a plastic suitcase. It's comfortable. The familiar stores and wears in the field in the aforementioned packages. Lipo is an ordinary battery and if not to close the contacts and do not pierce it through, it will not bring any trouble when stored and transport.

Operation LIPO.

Drop Lipo's battery lower than 3 volts on the bank is not recommended - can die. You can use sound indicators, but there is a chance that it will be boosted at the most inopportune moment and you will fallinate with the balls from the head to the head, as the last horse! The sound firm is connected to the balancing connector and how it will be stopped - it's time to change or get the secondary.

When the current consumption is consumed, more than the battery can give, Lipo strives to swell and die. So what should be followed by strictly! Use wattmeters to control.

When operating, there is another nuance - our 1000mAh 20c battery. The idea gives 20a. Motors usually allows you to exceed the recommended currents, by 20%, however, I exceeded and 80% 🙂

Actually maximum current speaking batteries are not very good. For example, I have 2200 20s gives current to 44a in just 2-3 minutes, then there is a stress drawdown, although it is obliged to give at least 5 minutes.

So, when choosing a Lipo battery, we look at the macmal current declared for the selected engine and we throw the stock. So for the motor, which eats 8-12a, our 1000mAh 20c is quite suitable, but for 16-18a I would choose or with a greater current, for example, 25-30C or took a greater container, for example 1600 20 ° C.

Lipo models are high-quality products from the field of radio-controlled electronics. Accumulators for them should also correspond to the quality and durability of radio-controlled products.

Charger lIPO device It is considered one of the most common devices in its field of activity. They are distinguished by power, charging speeds, housings and sizes. In sales they are presented in a great variety. There are accumulators for 1.6, 2.2, 2.65, 3.8, 4, 5, and even 6,000 milliam. Make them, mostly in a tough protective case, which makes the device more durable, protecting it from various mechanical damage.

Principle of operation

Lipo-battery is charged with 1C current (if not specified to charge differently on the battery itself. The case is, today, scientific and technological progress does not stand still, and chargers have already begun to appear with the possibility of recharging 2C and 5C- levels ). The basic charging current of this battery becomes from the 1st amp. For example, the battery for 2200 milliammeter requires 2.2 amps of the charge strength. Such is the order of charging will become for other types of chargers of this type.

The computerized charger performs the battery balancing (alignment of the volt load on each bank of the battery) during recharging. Although it is possible to charge using 2S batteries, without the help of the balancing cable, presented in the White Connector in the photo, it is strongly recommended to connect a balancing connector. 3S and more modern charging capabilities, you only need to use with a connected balancing wire. If you do not adhere to this instruction, you may overstry the device and fire in the house, later.

The computerized charger performs the battery balancing (alignment of the volt load on each bank of the battery) during recharging. Although it is possible to charge using 2S batteries, without the help of the balancing cable, presented in the White Connector in the photo, it is strongly recommended to connect a balancing connector. 3S and more modern charging capabilities, you only need to use with a connected balancing wire. If you do not adhere to this instruction, you may overstry the device and fire in the house, later.

Where is it profitable to acquire this type of charger?

Our online store is directly engaged in sales of high-quality radio engineering. We buy radio-controlled models and spare parts for them, exclusively in proven suppliers. We can choose charger for LIPO models highest quality For quite affordable funds.

To charge Lipo large capacity batteries, inexpensive charging balancers are not fully suitable due to a limited charging current, as a result of which the charge of high-capacity batteries (2 ... 5a) is stretched on a very long time. The proposed charger is designed to charge a 2S ... 3S Lipo of high-capacity batteries with their balancing and individual disconnection of cans, on which the voltage reached 4.2 volts.

This scheme is intended for charging 2s and 3s batteries, but if necessary, charge 4S or 5S batteries, it suffices to increase the number of cells. All cells are the same.

The principle of operation of the memory Consider on the example of one cell. The basis is the precision TL431 printridge with an adjustable inclusion threshold. The inclusion threshold is set by the resistive voltage divider at the output of the control electrode of Stabitron. Until the inclusion of Stabille, the entire charge current flows through the battery. Stabilodron through a resistor 1 kΩ is connected in parallel to the battery, and the voltage on the positive bus, as well as on the resistive divider (and on the control electrode of Stabilion) as the battery is charged gradually increases. When the voltage is reached on the battery, 4.2 volts opens a stabilion and from the voltage drop on the resistor 1 com, the CT816 power transistor opens. Charging current now passes through it. The signaling LED lights up. The chain of 4 sequentially connected powerful diodes and the transistor KE transition is a powerful stabilion with a stabilization voltage of about 4.2 volts, which prevents the battery discharge through an open transistor transition. Resistor * 1.5 kΩ pick up in such a way that when it is achieved at an appropriate battery bank +4.2 volt, Stabitron opened and the signal LED lights up.

Improved scheme.

TN36 transformer or similar.

CT816 transistors (collector current 3 A).

Diodes - Powerful DIP226 Dip Code diode with current of at least 2 A.

Powerful wire variable resistor 10 ... ..20 ohms for adjusting the charge current.

Ammeter 1 ... .3 A, to control the charge current.

Each transistor has a small radiator 20 x 40 mm of aluminum 1 mm.

The output voltage coming from the rectifier to the balancing should exceed the voltage of the charged battery. In the rectifier used diode bridge Current 3 A and condenser 2200 μF x 36 volts.

For one bank - voltage from the rectifier should be about 6 volts.

For two cans - voltage from the rectifier should be about 11 volts.

For three cans - voltage from the rectifier should be about 15 volts.

For four cans - voltage from the rectifier should be about 20 volts.

If necessary, you can switch the windings of the transformer.

Cutpacked voltage of a charged 4.2 volt bank.

The charge current for batteries is exhibited by a powerful wire variable resistor 10 ... 20 Ohms in the range of 1 ... 2 A, and for the batteries of a small container in the range of 0.5 A.

I use this charger for two years. I charge accumulators 1.8 ..........3.0 A.

Montup

Negative printed circuit board for three charged cells (3s Lipo). View from the tracks.

Option of structural execution of the memory. Front view. Diodes are burning - the charge is over.

Back view. A axis of the variable is visible wire resistor Current settings.

General view of the inside.

Pricing fee.

Seen - variable resistor, diode bridge, filter condenser.

Especially for skeptics and adherents of microcontrollers I want to say the following.

I do not deny the advantages of microcontrollers before the 80s technologies!

But the circuitry and technology of 80s are available even to novice radio amateurs, which cannot be said about microprocessors. In this article, I just want to show that on ordinary Soviet radio elements, you can, without much effort and material costs for a couple of days, to collect this or that the device you need!

Alexander Degtyarev, Vladikavkaz

Additional article

With a sequential charging method, one of the main requirements that must be ensured, the following is the voltage in any section of the charged lithium battery, when charging, should not exceed a certain value (the magnitude of this threshold depends on the type of lithium element). Ensure this requirement, with a consistent charge, without accepting special measures, it is impossible ... The reason is obvious - individual sections of the battery are not identical, so the achievement of the maximum allowable voltage on each of the sections when charging occurs at different times. There is a situation where we are required to charge, since the voltage on the part of the sections has already reached the maximum allowable threshold. At the same time, some of the sections remain underwent. This is bad mainly because the overall battery capacity is reduced, so we will have to stop the discharge of the battery at the moment when the voltage on the "weak" (underwent) section will reach its minimally allowable threshold.

To prevent the voltage to increase when charging, above a certain threshold, and the balance sheet serves. Its task is quite simple - monitor the voltage on a separate section, and, as soon as the voltage on it, it reaches a certain value when charging, give the command to turn on the power key, which connects the parallel charging section of the ballast resistor. At the same time, if the residual charging current (and it, closer to the end of the charging, is already small enough, due to the small difference in the potentials between the voltage on the charging battery and the voltage at the output of the charger) will be less (or equal) the current flowing through the ballast resistor, That raising the voltage on the charged section is to stop. In this case, charging the rest of the sections, the voltage on which has not yet reached the maximum allowable values \u200b\u200b- continue. The charging process will end in that the balancers of all battery sections will work. The voltage on all sections will be the same, and equal to the threshold to which balancers are configured. Charging current will be zero, since the voltage on the battery and the voltage at the output of the charger will be equal (there is no potential difference - there is no charging current). It will only be a current through ballast resistors. Its value is determined by the magnitude of consistently connected ballast resistors and voltage at the output of the charger.

The voltage control function itself, could easily perform any comparator, equipped with a support voltage ... But we don't have a comparator (more precisely, it is, but it is not convenient for us to use it). We have TL431. But the comparator from her, honestly, no. To compare the voltage with a reference, it knows how very well, but to give a clear, unambiguous command on the power key, it can not. Instead, when approaching the threshold, it smoothly begins to drive the power key into the active (half-open) mode, the key begins to warm much, and, in the end, we do not have a balancer, but a complete nonsense.

That is this problem that did not allow fully used TL431, it was possible to solve the other day. Larkor simply opened (but it had to open it for more than two years) - it was necessary to turn TL431, in the Schmitt trigger. What was done. It turned out the perfect balancer - accurate, thermostable, fairly simple, with a clear team on the power key.

Below - two schemes Balances calculated to control the LIFEPO4 and Li-Ion batteries.

Turn the TL431 to the Schmitt trigger, managed to add to p-N-P scheme Transistor T1 and resistor R5. It works so - the R3 divider, R4 is determined by the threshold of the controlled voltage. At a time when the voltage on the control electrode reaches 2.5 volts, the TL431 opens, the T1 transistor opens. At the same time, the collector's potential increases, and some of this voltage through the R5 resistor enters the TL431 control electrode circuit. At the same time, TL431 is avalanche-like enters the saturation. The scheme acquires a pronounced hysteresis - the switching on occurs at 3.6 volts, and shutdown - at 3.55 volts. At the same time, a control pulse with very steep edges is formed in the proliferation of the power key, and the power key entering the active mode is excluded. In a real scheme, at a current through a balancing resistor equal to 0.365 amps, the voltage drop at the transition of the stock source of the power key is only 5-6 mV. At the same time the key itself, always remains cold. What, in fact, was required. This scheme can be easily configured to control any voltage (divider R3, R4). The value of the maximum balance of balancing is determined by the R7 resistor and the voltage to the battery sections.

Briefly about accuracy. In the actually collected Balancir for five sections for the LIFEPO4 battery, the voltage at balancing was laid in the range of 3.6-3.7 volts (the maximum allowable voltage for LiFePO4 is 3.75 volts). Assembly resistors were used conventional (not precision). In my opinion - a very good result. I believe that it is not a special practical meaning in balancing, no particular practical meaning. But for many, it is rather a question of religion than physics. And they are entitled, and have the opportunity to achieve greater accuracy.

The figure below is a separate balance sheet board, and, for example, the balance sheet board for six sections. Obviously, cloning a single balance sheet board, you can easily make the balance sheet board for any number of sections and any proportions. Here is such a charging and balancing device I use now. I use the power supply described in the article about the inverter with adaptive restriction Current. But you can use any other stabilized power supply, improving its shunt.

Balancer is made in the form of a single board. It connects to the battery balancing connector during charging.

Couple words about components. TL431 and P-N-P bipolar transistor (it will suit almost any) in SOT23 enclosures, you can find on motherboards computers. In the same place, you can find the strength keys with "digital" levels. I used the CHM61A3PAPT (or it is possible - FDD8447L) in the TO-252A enclosures - fit perfectly, although the characteristics are very redundant (for currents up to 1a, you can find something in easier).

IN modern devices Lithium battery controls described above are assigned to a microcontroller. But it is much more complex for repetition of the device, and their use is not always justified. I think it's not bad when there is a choice.

So the balance sheet "live" looks like. For the quality of manufacture, again I apologize - due to time saving, again painted the board with a conventional permanent marker.

Cellular - what it is on the iPad and what's the difference

Cellular - what it is on the iPad and what's the difference Go to digital television: What to do and how to prepare?

Go to digital television: What to do and how to prepare? Social polls work on the Internet

Social polls work on the Internet Savin recorded a video message to the Tyuments

Savin recorded a video message to the Tyuments Menu of Soviet tables What was the name of Thursday in Soviet canteens

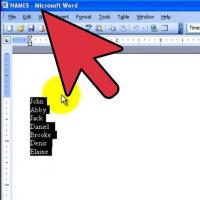

Menu of Soviet tables What was the name of Thursday in Soviet canteens How to make in the "Word" list alphabetically: useful tips

How to make in the "Word" list alphabetically: useful tips How to see classmates who retired from friends?

How to see classmates who retired from friends?