Powerful amplifier "Lanzar". Audio and sound Lanzar quiescent current not set

Frankly speaking, well, they did not expect that this scheme would cause so many difficulties when repeating it, and the thread on the Soldering Iron forum would cross the 100-page threshold. So we decided to put an end to this topic. Of course, when preparing materials, the material from this branch will be used, since it is simply not realistic to foresee some things - they are too paradoxical.

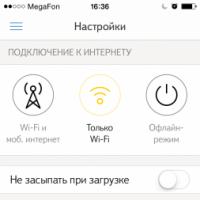

The Lanzar power amplifier has two basic circuits - the first is completely on bipolar transistors (Fig. 1), the second using field ones in the penultimate stage (Fig. 2). Figure 3 shows a diagram of the same amplifier, but made in the MC-8 simulator. The positional numbers of the elements practically coincide, so you can watch any of the diagrams.

Figure 1 Lanzar power amplifier circuit completely on bipolar transistors.

INCREASE

Figure 2 Lanzar power amplifier circuit using field-effect transistors in the penultimate stage.

INCREASE

Figure 3 Schematic of the LANZAR power amplifier from the MC-8 simulator. INCREASE

|

LIST OF ELEMENTS INSTALLED IN THE AMPLIFIER LANZAR |

|

|

FOR BIPOLAR VERSION |

FOR VARIANT WITH FIELDS |

| C3, C2 = 2 x 22µ0 C4 = 1 x 470p C6, C7 = 2 x 470µ0 x 25V C5, C8 = 2 x 0µ33 C11, C9 = 2 x 47µ0 C12, C13, C18 = 3 x 47p C15, C17, C1, C10 = 4 x 1µ0 C21 = 1 x 0µ15 C19, C20 = 2 x 470µ0 x 100V C14, C16 = 2 x 220µ0 x 100V R1 = 1 x 27k VD1, VD2 = 2 x 15V VT2, VT4 = 2 x 2N5401 |

C3, C2 = 2 x 22µ0 C4 = 1 x 470p C6, C7 = 2 x 470µ0 x 25V C5, C8 = 2 x 0µ33 C11, C10 = 2 x 47µ0 C12, C13, C18 = 3 x 47p C15, C17, C1, C9 = 4 x 1µ0 C21 = 1 x 0µ15 C19, C20 = 2 x 470µ0 x 100V C14, C16 = 2 x 220µ0 x 100V R1 = 1 x 27k VD1, VD2 = 2 x 15V VT8 = 1 x IRF640 |

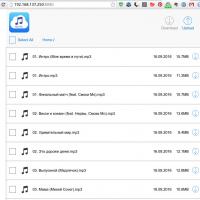

The drawing of a printed circuit board in the LAY format has two types - one developed by us and is used for assembling and selling power amplifier boards, as well as an alternative version developed by one of the participants in the SOLDERING IRON forum. The boards are quite different. Figure 4 shows a sketch of our power amplifier board, Figure 5 - an alternative.

Figure 5 Sketch of the printed circuit board of the LANZAR power amplifier. DOWNLOAD

Figure 6 Sketch of an alternative PCB for the LANZAR power amplifier. DOWNLOAD

ATTENTION! THE BOARD HAS AN ERROR - CHECK!

The parameters of the power amplifier are summarized in the table:

|

PARAMETER |

power amplifier schematic diagram of Lanzar power amplifier description of operation recommendations for assembly and adjustment | |||||||||||||||||||||||||||||||||||||||||||||||||

|

ON LOAD |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 Ohm |

||||||||||||||||||||||||||||||||||||||||||||||||||

| Maximum supply voltage, ± V | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Maximum output power, W with distortions up to 1% and supply voltage: |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

| ± 30V | ||||||||||||||||||||||||||||||||||||||||||||||||||

| ± 35V | ||||||||||||||||||||||||||||||||||||||||||||||||||

| ± 40V | ||||||||||||||||||||||||||||||||||||||||||||||||||

| ± 45V | ||||||||||||||||||||||||||||||||||||||||||||||||||

| ± 55V | ||||||||||||||||||||||||||||||||||||||||||||||||||

| ± 65V |

240 |

For example, let's take the supply voltage equal to ± 60 V. If the installation is done correctly and there are no defective parts, then we get the voltage map shown in Figure 7. The currents flowing through the elements of the power amplifier are shown in Figure 8. The power dissipation of each element is shown in Figure 9 (about 990 mW is dissipated on transistors VT5, VT6, therefore the TO-126 package requires a heat sink).

A few words about details and installation:

The question was raised about the advisability of using ceramic resistors in the emitter circuits of terminal transistors. You can also use MLT-2, two each, connected in parallel with a nominal value of 0.47 ... 0.68 Ohm. However, the distortions introduced by ceramic resistors are too small, but the fact that they are discontinuous - when overloaded, they are interrupted, i.e. their resistance becomes infinite, which quite often leads to the rescue of terminal transistors in critical situations.

Before installing the power transistors, as well as in case of suspicion of their breakdown, the power transistors are checked by a tester. The limit on the tester is set for diode testing (Figure 13).

Is it worth picking up transistors by coffee. gain? There are quite a few disputes on this topic and the idea of selecting elements has been going on since the deep seventies, when the quality of the element base left much to be desired. Today, the manufacturer guarantees the spread of parameters between transistors of the same batch of no more than 2%, which in itself speaks of good quality elements. In addition, given that the terminal transistors 2SA1943 - 2SC5200 have firmly established themselves in sound engineering, the manufacturer began to release paired transistors, i.e. transistors of both forward and reverse conductivity already have the same parameters, i.e. the difference is not more than 2% (Fig. 14). Unfortunately, such pairs are not always found on sale, nevertheless, several times we have bought "twins". However, even with a parsing of coffee. gain between forward and reverse conduction transistors, it is only necessary to ensure that the transistors of the same structure are of the same batch, since they are connected in parallel and the spread in h21 can cause an overload of one of the transistors (for which this parameter is higher) and, as a consequence, overheating and exit from building. Well, the spread between transistors for positive and negative half-waves is fully compensated by negative feedback.

The same applies to differential cascade transistors - if they are of the same batch, i.e. bought at the same time in one place, then the chance that the difference in parameters will be more than 5% is VERY small. Personally, we like the FAIRCHALD transistors 2N5551 - 2N5401 more, but the STs sound quite decent too.

Pass-through capacitors C1-C3, C9-C11 have a not quite typical inclusion, in comparison with factory analogs of amplifiers. This is due to the fact that with such a connection, a rather large capacitor is not obtained, but the use of a 1 μF film capacitor compensates for the not entirely correct operation of electrolytes at high frequencies. In other words, this implementation made it possible to obtain a more pleasant amplifier sound, compared to one electrolyte or one film capacitor.

Replacing the resistors with diodes VD3 and VD4, we get the voltages shown in Figure 17. As you can see from the figure, the amplitude of the ripple on the collectors of the terminal transistors has hardly changed, but the supply voltage of the voltage amplifier has acquired a completely different form. First of all, the amplitude decreased from 1.5 V to 1 V, and also at the moment when the peak of the signal passes, the supply voltage of the VN sags only to half the amplitude, i.e. by about 0.5 V, while when using a resistor, the voltage at the peak of the signal sags 1.2 V. In other words, by simply replacing the resistors with diodes, it was possible to reduce the power ripple in the voltage amplifier by more than 2 times.

Despite the fact that on the simulator, the optimal constant voltage was obtained only with R1 equal to 8.2 kOhm, in real amplifiers, this nominal value is 15 kOhm ... 27 kOhm, depending on which manufacturer the transistors of the VT1-VT4 differential cascade are used.

In other words, a decrease in THD by replacing field-effect transistors leads to a "shortage" of about 30 W, and a decrease in the THD level by about 2 times, so it is up to everyone to decide what to set. Well, now a few words about the most common mistakes when assembling an amplifier yourself.

The next popular mistake is installation of transistors "upside down", i.e. when the collector and emitter are confused in places. In this case, constant tension is also observed, the absence of any signs of life. True, the reverse switching on of the differential cascade transistors can lead to their failure, but then how lucky. An inverted voltage map is shown in Figure 21.

Often transistors 2N5551 and 2N5401 are confused in places, and they can also confuse the emitter with the collector. Figure 22 shows the voltage map of the amplifier with the "correct" installation of the transistors tangled in places, and in Figure 23 - the transistors are not only reversed, but also inverted.

If the transistors are confused in places, and the emitter-collector are soldered correctly, then a small constant voltage is observed at the output of the amplifier, the quiescent current of the window transistors is regulated, but the sound is either completely absent, or at the level "it seems to be playing". Before mounting the transistors soldered in this way on the board, they should be checked for operability. If the transistors are interchanged, and even the emitter-collector are interchanged, then the situation is already quite critical, since in this version for the differential cascade transistors the polarity of the applied voltage is correct, but the operating modes are violated. In this version, there is a strong heating of the terminal transistors (the current flowing through them is 2-4 A), a small constant voltage at the output and a barely audible sound.

Sometimes the transistors of the last stage of the voltage amplifier are confused in places. In this case, there is a small constant voltage at the output of the amplifier, the sound, if there is, is very weak and with huge distortions, the quiescent current is regulated only upward. An amplifier voltage map with this error is shown in Figure 25.

The penultimate stage and terminal transistors in the amplifier are rarely confused in places, so this option will not be considered.

Figure 27 shows a voltage map in a situation when the terminals are out of order and have the lowest possible resistance, i.e. short-circuited. This variant of the malfunction drives the amplifier into VERY harsh conditions and further burning of the amplifier is limited only by the power source, since the current consumed at this moment can exceed 40 A. in the place where the short circuit to the power bus actually occurred. However, it is this situation that belongs to the easiest diagnostics - it is enough to check the resistance of the transitions between themselves with a multimeter before turning on the amplifier, without even soldering them from the amplifier. The measurement limit set on the multimeter is DIODE CHECK or AUDIBLE RING. As a rule, burnt-out transistors show resistance between junctions in the range from 3 to 10 ohms.

The amplifier will behave in the same way in the event of a breakdown of the penultimate stage - when the leads are burned off, only one half-wave of the sinusoid will be reproduced, with a short circuit of the transitions - huge consumption and heating.

If the transistor in the last stage of the VT5 voltage amplifier fails and its transitions are closed, then with the connected load, the output will have a rather large constant voltage and a direct current flowing through the load, of the order of 2-4 A. If the load is disconnected, then the output voltage the amplifier will be almost equal to the positive power rail (Figure 29).

Finally, it remains only to offer a few oscillograms at the most focal points of the amplifier:

It remains only to explain about the power supply. First of all, the power of a network transformer for a power amplifier of 300 W should be at least 220-250 W and this will be enough to reproduce even very tough compositions. In other words, if you have a transformer from a tube color TV, then this is an IDEAL TRANSFORMER for one amplifier channel that allows you to easily reproduce musical compositions with a power of up to 300-320 watts. Finally, it remains to add that not everyone needs a power of 200-300 W, therefore printed circuit board was redesigned for one pair of terminal transistors. This file was made by one of the visitors to the forum site "SOLDERING" in the program SPRINT-LAYOUT-5 (DOWNLOAD THE BOARD). Details about this program can be found. | ||||||||||||||||||||||||||||||||||||||||||||||||

POWER AMPLIFIER LANZAR OVERVIEW

To be honest, I was very surprised by the growing popularity of the expression SOUND AMPLIFIER. As far as my worldview permits, only one object can appear under the sound amplifier - a horn. Here he really amplifies the sound for more than a dozen years. Moreover, a horn can amplify sound in both directions.

As you can see from the photo, the horn has nothing to do with electronics, nevertheless, the search queries POWER AMPLIFIER are increasingly being replaced by SOUND AMPLIFIER, and the full name of this device AF POWER AMPLIFIER is entered only 29 times a month against 67,000 requests SOUND AMPLIFIER.

It's really interesting what this is connected with ... But it was a prologue, and now the fairy tale itself itself:

The schematic diagram of the LANZAR power amplifier is shown in Figure 1. This is an almost typical symmetrical circuit, which made it possible to seriously reduce nonlinear distortion to a very low level.

This scheme has been known for a long time, back in the eighties Bolotnikov and Ataev presented a similar scheme based on the domestic element base in the book "Practical schemes for high-quality sound reproduction". However, work with this circuitry did not begin with this amplifier.

It all started with the PPI 4240 car amplifier circuit which was successfully repeated:

Schematic diagram of the PPI 4240 car amplifier

Then there was an article "Opening the amplifier -2" by Iron Shikhman (the article was unfortunately removed from the author's site). It dealt with the circuitry of the Lanzar RK1200C car amplifier, where the same symmetrical circuitry was used as the amplifier.

It is clear that it is better to see once than hear a hundred times, therefore, delving into my hundred years of recorded discs, I found the original article and cite it as a quote:

WE OPEN THE AMPLIFIER - 2

A.I.Shikhatov 2002

A new approach to the design of amplifiers involves the creation of a line of devices using similar circuitry solutions, common units and styling. This allows, on the one hand, to reduce the cost of design and manufacture, on the other hand, expands the choice of equipment when creating an audio system.

Lanzar's new line of RACK amplifiers is inspired by rack-mountable studio equipment. The front panel with dimensions of 12.2x2.3 inches (310x60mm) contains controls, and the rear panel contains all connectors. This arrangement not only improves the appearance of the system, but also simplifies the work - the cables do not interfere. On the front panel, you can mount the included mounting brackets and carrying handles, then the unit takes on a studio look. The ring illumination of the sensitivity control only enhances the similarity.

Radiators are located on the side surface of the amplifier, which allows you to rack up multiple devices without disturbing their cooling. This is an undoubted convenience when creating deployed audio systems. However, when installing in a closed rack, you need to worry about air circulation - install supply and exhaust fans, temperature sensors. In a word, professional equipment requires a professional approach in everything.

The line includes six two-channel and two four-channel amplifiers, differing only in output power and body length.

The block diagram of the crossover of the Lanzar RK series amplifiers is shown in Figure 1. The detailed diagram is not given, since there is nothing original in it, and this node does not determine the main characteristics of the amplifier. The same or similar structure is used in most modern mid-range amplifiers. The feature set and performance has been optimized for many factors:

On the one hand, the crossover capabilities should allow building standard audio system options (front plus subwoofer) without additional components. On the other hand, to introduce full set functions in the built-in crossover do not make much sense: This will significantly increase the cost, but in many cases it will remain unclaimed. It is more convenient to perform complex tasks on external crossovers and equalizers, and turn off the built-in ones.

The design uses dual KIA4558S operational amplifiers. These are low-noise, low intrinsic distortion amplifiers designed with "sonic" applications in mind. As a result, they are widely used in pre-amplification stages and crossover.

The first stage is a linear amplifier with variable gain. It matches the output voltage of the signal source with the sensitivity of the power amplifier, since the gain of all other stages is equal to unity.

The next stage is the bass boost control. In amplifiers of this series, it allows you to increase the signal level at a frequency of 50 Hz by 18 dB. In the products of other companies, the rise is usually less (6-12 dB), and the tuning frequency can be in the region of 35-60 Hz. By the way, such a regulator requires a good headroom of the amplifier: an increase in gain by 3 dB corresponds to doubling the power, by 6 dB - to quadrupling, and so on.

This is reminiscent of the legend about the inventor of chess, who asked the rajah for one grain for the first cell of the board, and for each subsequent cell - twice as many grains as for the previous one. The frivolous Rajah could not fulfill his promise: there was no such amount of grains on the whole Earth ... We are in a more advantageous position: an increase in the level by 18 dB will increase the signal power "only" by 64 times. In our case, 300 W is available, but not every amplifier can boast of such a margin.

Further, the signal can be fed directly to the power amplifier, or the required frequency band can be selected with filters. The crossover section consists of two independent filters. The low-pass filter is tunable in the 40-120 Hz range and is designed to work exclusively with a subwoofer. The HPF tuning range is noticeably wider: from 150 Hz to 1.5 kHz. As such, it can be used to work with a wideband front or for the MF-HF band in a system with channel-by-channel amplification. The limits of adjustment, by the way, were chosen for a reason: in the range from 120 to 150 Hz, a "hole" is obtained, in which the acoustic resonance of the cabin can be hidden. It is also noteworthy that the bass booster is not disabled in any of the modes. The use of this stage simultaneously with the high-pass filter allows you to adjust the frequency response in the resonance region of the cabin no worse than with an equalizer.

The last cascade is with a secret. Its task is to invert the signal in one of the channels. This will allow using the amplifier in a bridge connection without additional devices.

Structurally, the crossover is made on a separate printed circuit board, which is connected to the amplifier board using a connector. This solution allows for the entire line of amplifiers to use only two crossover options: two-channel and four-channel. The latter, by the way, is just a "doubled" version of the two-channel and its sections are completely independent. The main difference is the changed PCB layout.

Amplifier

The Lanzar power amplifier is made according to a typical scheme for modern designs, shown in Figure 2. With minor variations, it can be found in most amplifiers of the middle and lower price category. The only difference is in the types of parts used, the number of output transistors and the supply voltage. The diagram of the amplifier's right channel is shown. The left channel layout is exactly the same, only part numbers start with 1 instead of 2.

A filter R242-R243-C241 is installed at the amplifier input, which eliminates radio frequency interference from the power supply. Capacitor C240 does not allow DC input to the power amplifier. These circuits do not affect the frequency response of the amplifier in the audio frequency range.

To avoid clicks at the moments of switching on and off, the input of the amplifier is closed to the common wire with a transistor switch (this node is discussed below, together with the power supply). Resistor R11A excludes the possibility of self-excitation of the amplifier when the input is closed.

The amplifier circuit is fully balanced from input to output. A double differential stage (Q201-Q204) at the input and a stage on transistors Q205, Q206 provide voltage amplification, the remaining stages provide current amplification. A stage on the Q207 transistor stabilizes the quiescent current of the amplifier. To eliminate its "asymmetry" at high frequencies, it is shunted with a mylar capacitor C253.

The driver stage on transistors Q208, Q209, as befits a preliminary stage, operates in class A. A "floating" load is connected to its output - resistor R263, from which the signal is taken to excite the transistors of the output stage.

The output stage uses two pairs of transistors, which made it possible to remove from it 300 W of nominal power and up to 600 W of peak power. Resistors in the base and emitter circuits eliminate the consequences of technological variation in the characteristics of transistors. In addition, resistors in the emitter circuit serve as current sensors for the overload protection system. It is made on the Q230 transistor and controls the current of each of the four transistors of the output stage. When the current through a separate transistor increases to 6 A or the current of the entire output stage to 20 A, the transistor opens, issuing a command to the blocking circuit of the supply voltage converter.

The gain is set by the negative feedback circuit R280-R258-C250 and is equal to 16. Correction capacitors C251, C252, C280 ensure the stability of the amplifier covered by the OOS. The R249, C249 circuit included at the output compensates for the increase in load impedance at ultrasonic frequencies and also prevents self-excitation. In the audio circuits of the amplifier, only two electrolytic non-polar capacitors are used: C240 at the input and C250 in the OOS circuit. Due to their large capacity, it is extremely difficult to replace them with other types of capacitors.

Power supply Power supply high power made on field-effect transistors. A special feature of the power supply is the separate output stages of the converter for powering the power amplifiers of the left and right channels. This structure is typical for amplifiers increased power and allows you to reduce crosstalk between channels. A separate LC filter in the power supply circuit is provided for each converter (Figure 3). Diodes D501, D501A protect the amplifier from erroneous switching in the wrong polarity.

Each converter uses three pairs of field-effect transistors and a transformer wound on a ferrite ring. The output voltage of the converters is rectified by diode assemblies D511, D512, D514, D515 and smoothed by filtering capacitors with a capacity of 3300 uF. The output voltage of the converter is not stabilized, therefore the power of the amplifier depends on the voltage of the on-board network. From the negative voltages of the right and positive voltages of the left channel, the parametric stabilizers generate voltages of +15 and -15 volts to power the crossover and differential stages of power amplifiers.

The master oscillator uses a KIA494 (TL494) microcircuit. Transistors Q503, Q504 power up the output of the microcircuit and accelerate the closing of the key transistors of the output stage. The supply voltage is constantly applied to the master oscillator, the switching on is controlled directly from the Remote circuit of the signal source. This solution simplifies the design, but in the off state the amplifier consumes a negligible quiescent current (several milliamps).

The protection device is made on a KIA358S microcircuit containing two comparators. The supply voltage is applied to it directly from the Remote circuit of the signal source. Resistors R518-R519-R520 and a temperature sensor form a bridge, the signal from which is fed to one of the comparators. The signal from the overload sensor is fed to the other comparator through the driver on the Q501 transistor.

When the amplifier overheats, a high voltage level appears at pin 2 of the microcircuit, the same level occurs at pin 8 when the amplifier is overloaded. In any of the emergency cases, the signals from the output of the comparators through the diode OR circuit (D505, D506, R603) block the work of the master oscillator at pin 16. The operation is restored after the causes of the overload or the amplifier cooling below the temperature sensor response threshold are eliminated.

The overload indicator is originally made: the LED is switched on between the +15 V voltage source and the on-board network voltage. During normal operation, voltage is applied to the LED in reverse polarity and is not illuminated. When the converter is blocked, the +15 V voltage disappears, the overload indicator LED turns on between the on-board voltage source and the common wire in the forward direction and starts to glow.

On transistors Q504, Q93, Q94, a device for blocking the input of the power amplifier is made for the duration of transient processes when turning on and off. When the amplifier is turned on, the capacitor C514 is slowly charged, the transistor Q504 is in the open state at this time. The signal from the collector of this transistor opens the keys Q94, Q95. After charging the capacitor, the Q504 transistor closes, and the -15 V voltage from the power supply output reliably blocks the keys. When the amplifier is turned off, the Q504 transistor instantly opens through the diode D509, the capacitor quickly discharges and the process repeats in the reverse order.

Design

The amplifier is mounted on two printed circuit boards. One of them contains an amplifier and a voltage converter, the other contains crossover elements and indicators for switching on and overload (not shown in the diagrams). The boards are made of high-quality fiberglass with a protective coating of the tracks and are mounted in a case made of an aluminum U-section. Powerful transistors of the amplifier and power supply are pressed against the side shelves of the case by means of overlays. Profiled radiators are attached to the outside to the sidewalls. Front and rear panel amplifiers are made of anodized aluminum profile. The whole structure is fastened with self-tapping screws with hexagon heads. That, in fact, is all - the rest can be seen in the photographs.

As you can see from the article, the original LANZAR amplifier itself is not bad enough, but I wanted better ...

I went to the forums, of course, to Vegalab, but I didn't find much support - only one person responded. Perhaps it's for the best - there are not a bunch of co-authors. Well, in general, this appeal can be considered the birthday of Lanzar - at the time of writing the comment, the board had already been etched and sealed almost completely.

So Lanzar is ten years old ...

After several months of experiments, the first version of this amplifier, called "LANZAR", was born, although of course it would be fair to call it "PIPIAI" - it all started with him. However, the word LANZAR sounds much nicer to the ear.

If someone SUDDENLY considers the name to be an attempt to play on the brand name, then I dare to assure him that nothing of the kind was in my thoughts and the amplifier could get absolutely any name. However, he became LANZROM in honor of the LANZAR company, since it is this car equipment that falls into that small list that is personally respected by the team that worked on fine-tuning this amplifier.

A wide range of supply voltages makes it possible to build an amplifier with a power from 50 to 350 W, and at powers up to 300 W at the UMZCH box. nonlinear distortion does not exceed 0.08% in the entire audio range, which allows the amplifier to be classified as Hi-Fi.

The figure shows the appearance of the amplifier.

The amplifier circuit is fully balanced from input to output. A double differential stage (VT1-VT4) at the input and a cascade on transistors VT5, VT6 provide voltage amplification, the remaining stages provide current amplification. The VT7 transistor stage stabilizes the quiescent current of the amplifier. To eliminate its "unbalance" at high frequencies, it is shunted by a capacitor C12.

The driver stage on transistors VT8, VT9, as befits a preliminary stage, operates in class A. A "floating" load is connected to its output - a resistor R21, from which a signal is taken to excite the transistors of the output stage. The output stage uses two pairs of transistors, which made it possible to remove up to 300 W of nominal power from it. Resistors in the base and emitter circuits eliminate the consequences of the technological variation in the characteristics of transistors, which made it possible to abandon the selection of transistors in terms of parameters.

We remind you that when using transistors of the same batch, the spread in parameters between the transistors does not exceed 2% - this is the manufacturer's data. In reality, it is extremely rare for parameters to go beyond the three percent zone. The amplifier uses only "one party" terminal transistors, which, together with the balancing resistors, made it possible to maximally align the operating modes of the transistors with each other. However, if the amplifier is made for oneself, a loved one, then it will not be useless to assemble the test stand given at the end of THIS ARTICLE.

Regarding the circuitry, it remains only to add that such a circuitry solution gives one more advantage - complete symmetry eliminates transients in the final stage (!), I.e. at the moment of switching on, there are no overshoots at the output of the amplifier, which are characteristic of most discrete amplifiers.

Figure 1 - schematic diagram of the amplifier LANZAR. INCREASE .

Figure 2 - external view of the amplifier LANZAR V1.

Figure 3- external view of the amplifier LANZAR MINI

Schematic diagram of a powerful pop power amplifier 200 W 300 W 400 W high quality transistor amplifier Hi-Fi UMZCH

Power amplifier specifications:

390

As you can see from the characteristics - the Lanzar amplifier is very versatile and can be successfully used in any power amplifiers where good characteristics UMZCH and high output power.

You can, of course, praise this amplifier for quite a long time, however, it is not modest to engage in self-praise. Therefore, we decided to look at the reviews of those who heard how it works. I didn't have to search for a long time - this amplifier has been discussed for a long time on the Soldering Iron forum, so see for yourself: There were, of course, negative ones, but the first from an incorrectly assembled amplifier, the second from an unfinished version on a domestic configuration ... The audio frequency power amplifier UM LANZAR based on powerful bipolar transistors will allow you to assemble a very high quality amplifier audio frequency. Power supply ± 70 V - 3.3 kOhm ... 3.9 kOhm Of course, ALL resistors are 1 W, zener diodes at 15V, preferably 1.3 W By heating VT5, V6 - in this case, you can increase the radiators on them or increase their emitter resistors from 10 to 20 ohms. About the capacitors of the power supply filter of the LANZAR amplifier: |

Since this amplifier is quite popular and quite often questions about its self-production the following articles were written:

Transistor amplifiers. Circuitry basics

Transistor amplifiers. Building a balanced amplifier

Tuning Lanzar and changing circuitry

Adjustment of the power amplifier LANZAR

Increasing the reliability of power amplifiers using the example of a LANZAR amplifier

The penultimate article rather intensively uses the results of parameter measurements using the MICROCAP-8 simulator. How to use this program is described in detail in a trilogy of articles:

AMPovichok. CHILDREN'S

AMPovichok. YOUTHFUL

AMPovichok. ADULT

BUY TRANSISTORS FOR AMPLIFIER LANZAR |

|

And finally, I would like to give the impression of one of the fans this scheme who assembled this amplifier on his own:

The amplifier sounds very good, the high damping factor introduces a very different level of bass reproduction, and the high slew rate does an excellent job of reproducing even the smallest sounds in the high and midrange ranges.

You can talk a lot about the delights of sound, but the main advantage of this amplifier is that it does not add any color to the sound - it is neutral in this regard, and only repeats and amplifies the signal from the sound source.

Many who heard the sound of this amplifier (assembled according to this scheme) gave the highest praise for its sound, as a home amplifier for high-quality speakers, and its endurance in * close to military * conditions gives the chance to use it professionally for sounding various outdoor events , as well as in the halls.

For a simple comparison, I will give an example that will be most relevant among radio amateurs, as well as among those already * experienced in good sound *

in the musical phonogram Gregorian-Moment of Peace, the monks' choir sounds so realistic that it seems as if the sound goes right through, and the female vocals sound as if the singer is standing right in front of the listener.

When using time-tested speakers such as 35ac012 and the like, the speakers get a new breath and even at maximum volume they sound just as clearly.

For example, for lovers of loud music, when listening to the music track Korn ft. Skrillex - Get Up

The speakers were able to play all the difficult moments with confidence and without noticeable distortion.

As opposed to this amplifier, an amplifier was taken on the TDA7294, which already at a power of less than 70 watts per channel was able to overload 35ac012 so that it was clearly audible how the woofer coil beats against the core, which is fraught with speaker breakdown and, as a result, losses.

What can not be said about the * LANZAR * amplifier - even with a power of about 150W supplied to these speakers, the speakers continued to work perfectly, and the woofer was so well controlled that no extraneous sounds it just wasn't.

In the musical composition Evanescence - What You Want

The scene is so elaborate that you can even hear the beat of the drumsticks against each other And in the composition Evanescence - Lithium Official Music Video

The skip part is replaced by an electric guitar, so the hair on your head just starts to move, because there is simply no * tightness * of the sound, and fast transitions are perceived as if Formula 1 hurts in front of you, one moment and YOU are immersed in a new world. Not for the vocal, which throughout the entire composition brings generalization to these transitions, giving harmony.

In Nightwish - Nemo

Percussion sounds like gunshots, clearly and without a frame, and the thunderclaps at the beginning of the composition just make you look around.

Armin van Buuren ft. Sharon den Adel - In and Out of Love

We again plunge into the world of sounds that permeate us through and through, giving a sense of presence (and this without any equalizers and additional enhancements of the stereo base)

Johnny Cash Hurt

We again plunge into the world of harmonious sound, and the vocals and guitar sound so clearly that even the increasing tempo of the performance is perceived as if we are sitting behind the wheel of a powerful car and press the gas pedal to the floor, while not letting go but pressing harder.

With a good sound source and good acoustics, the amplifier does not * bother * at all * even at the highest volume.

Once a friend was visiting me and I wanted to listen to him what this amplifier is capable of, he turned the track in the AAC Eagles - Hotel California format at full volume, while instruments began to fall from the table, the chest felt as if well delivered punches of a boxer , the glass rang in the wall, and it was quite comfortable for us to listen to music, while the room was 14.5m2 with a 2.4m ceiling.

We put ed_solo-age_of_dub, the glass in two doors cracked, the sound was felt with the whole body, but the head did not hurt.

The board on the basis of which the video was made in the LAY-5 format.

If you assemble two LANZAR amps, can you turn them on with a bridge?

You can, of course, but first, a little lyrics:

For a typical amplifier, the output power depends on the supply voltage and load resistance. Since we know the load resistance, and we already have power supplies, it remains to be seen how many pairs of output transistors to take.

Theoretically, the total output power of the alternating voltage is the sum of the power given by the output stage, which consists of two transistors - one n-p-n, the second p-n-p, therefore each transistor is loaded at half the total power. For a sweet couple 2SA1943 and 2SC5200, the thermal power is 150 W, therefore, based on the above conclusion, 300 W can be removed from one pair of outputs.

But only practice shows that in this mode the crystal simply does not have time to give off heat to the radiator and thermal breakdown is guaranteed, because the transistors must be insulated, and the insulating gaskets, no matter how thin they are, still increase the thermal resistance, and the surface of the radiator is unlikely who polishes to micron precision ...

So for normal operation, for normal reliability, quite a few have adopted several different formulas for calculating the required number of output transistors - the output power of the amplifier should not exceed the thermal power of one transistor, and not the total power of a pair. In other words - if each transistor of the output stage can dissipate 150 W, then the output power of the amplifier should not exceed 150 W, if there are two pairs of output transistors, then the output power should not exceed 300 W, if three - 450, if four - 600.

Well, now the question is - if a typical amplifier can deliver 300W and we turn on two such amplifiers with a bridge, then what will happen?

That's right, the output power will approximately double, but the thermal power dissipated by transistors will increase 4 times ...

So it turns out that to build a bridge circuit, you will need not 2 pairs of outputs, but 4 on each half of the bridge amplifier.

And immediately we ask ourselves the question - is it necessary to drive 8 pairs of expensive transistors to get 600 W, if you can get by with four pairs simply by increasing the supply voltage?

Well, there, of course, is the master's business ...

Well, several options for PCBs for this amplifier will not be superfluous. There are also author's options, there are taken from the Internet, so it is better to double-check the board - there will be a training for the mind and less problems during the adjustment of the assembled version. Some options have been corrected, so there may be no errors, or maybe something escaped ...

One more question remained uncovered - assembly of the amplifier LANZAR on the domestic element base.

Of course, I understand that crab sticks are not made from crabs, but from fish. So is Lanzar. The fact is that in all attempts to build on domestic transistors the most running ones are used - KT815, KT814, KT816, KT817, KT818, KT819. These transistors and boxes have less amplification and unity gain, so you will not hear the Lanzar sound. But there is always an alternative. At one time, Bolotnikov and Ataev proposed something similar in circuitry, and it was also quite good-sounding:

You can see the details of how much power a power supply is needed for a power amplifier in the video below. The STONECOLD amplifier is taken as an example, but this measurement gives an understanding that the power of the mains transformer can be less than the power of the amplifier by about 30%.

At the end of the article, I would like to note that this amplifier needs a BIPOLAR power supply, since the output voltage is formed from the positive and negative side of the power supply. The diagram of such a power supply is shown below:

About the overall power of the transformer, conclusions can be made by watching the video above, but for the rest of the details I will make a small explanation.

The secondary winding must be wound with a wire, the cross-section of which is calculated for the overall power of the transformer plus a correction for the shape of the core.

For example, we have two channels of 150 W each, therefore, the overall power of the transformer must be at least 2/3 of the power of the amplifier, i.e. with an amplifier power of 300 W, the power of the transformer must be at least 200 W. With a power supply of ± 40 V to a load of 4 Ohms, the amplifier just develops about 160 W per channel, therefore the current flowing through the wire has a value of 200 W / 40 V = 5 A.

If the transformer has an W-shaped core, then the tension in the wire should not exceed 2.5 A per square mm of cross-section - this way the heating of the wire is less, and the voltage drop is less. If the core is toroidal, then the tension can be increased to 3 ... 3.5 A per 1 square mm of wire cross-section.

Based on the above, for our example, the secondary must be wound with two wires and the beginning of one winding is connected to the ends of the second winding (the connection point is marked in red). The wire diameter is D = 2 x √S / π.

With a tension of 2.5 A, we get a diameter of 1.6 mm, with a tension of 3.5 A, we get a diameter of 1.3 mm.

Diode bridge VD1-VD4 not only must calmly withstand the resulting current of 5 A, it must withstand the current that occurs at the moment of switching on, when it is necessary to charge the capacitors of the power filter C3 and C4, and the higher the voltage, the higher the capacitance, the higher the value of this starting current. Therefore, the diodes must be at least 15 Amperes for our example, and in the case of an increase in the supply voltage and the use of amplifiers with two pairs of transistors in the final stage, diodes of 30-40 amperes or a soft start system are needed.

The capacitance of capacitors C3 and C4 based on the Soviet circuitry is 1000 μF for every 50 W of amplifier power. For our example, the total output power is 300 W, this is 6 times 50 W, therefore the capacitance of the power filter capacitors should be 6000 μF per shoulder. But 6000 is not a typical value, so we round up to the typical value and get 6800 uF.

Frankly speaking, such capacitors do not come across often, so we put 3 2200 uF capacitors in each arm and get 6600 uF, which is quite acceptable. The question can be solved somewhat easier - use one 10,000 uF capacitor

Photo sent by Alexander (Allroy), Novorossiysk

On occasion I got the "modernized" power amplifier "Oda-UM102S". The modernization was carried out by an unknown master so severely that only good "meaty" radiators survived. So I decided to adapt my new project to them, which smoothly flowed out due to the desire to try out a new idea in hardware.

Historical reference

Historical reference

Since 1986, the "Oda 102 Stereo" stereo radio complex has been produced by the Murom plant "RIP". The complex provided reception of mono and stereo broadcasts in the VHF range, recording of mono and stereo programs, followed by playback. The complex consisted of 5 functionally complete units: VHF tuner "Oda-102S", cassette tape recorder-set-top box "Oda-302S", power amplifier "Oda UM-102S", pre-amplifier"Oda UP-102S" and 2 acoustic systems "15AS-213".

Fragment is excluded. Our magazine exists on donations from readers. The full version of this article is available only

How to make L1 I, but if someone is annoyed by this option, then the coil can be wound on a 2-watt 10-33 Ohm resistor with a wire with a diameter of 0.8 mm in one layer.

VT5, VT6 are equipped with small heatsinks, which are a 10 × 20 mm aluminum plate.

--

Thank you for the attention!

Igor Kotov, editor-in-chief of the magazine "Datagor"

Thank you for the attention!

Andrey Zelenin,

Kyrgyzstan, Bishkek

Lanzar is a high-quality Hi-Fi class AB transistor amplifier with high output power. In the course of the article, I will explain in as much detail the assembly process and configuration of the specified amplifier in the language of a novice radio amateur. But before we start talking about him, let's look at the amplifier parameters plate.

| PARAMETER | power amplifier schematic diagram of Lanzar power amplifier description of operation recommendations for assembly and adjustment | ||

| ON LOAD |

|||

| 2 Ohm |

|||

| Maximum supply voltage, ± V | |||

| Maximum output power, W with distortions up to 1% and supply voltage: | |||

| ± 30V | |||

| ± 35V | |||

| ± 40V | |||

| ± 45V | |||

| ± 55V | |||

| ± 65V | 240 | One of the important parameters is nonlinear distortion, at 2/3 of the maximum power it is 0.04%, at a maximum power of 0.08-0.1% - almost and allows this amplifier to be classified as a Hi-Fi rather high level. Lanzar is a symmetrical amplifier and is built entirely on complementary switches, the schematic has been known since the 70s. The maximum output power of an amplifier with 2 pairs of output switches for a load of 4 ohms with a bipolar power supply of 60 volts is 390 watts under a sinusoidal signal of 1 kHz. Some strongly disagree with this statement, I personally never tried to remove the maximum power, the maximum managed to get 360 watts with a stable 4 Ohm load during the tests, but I think it is quite possible to remove the indicated power, of course, the distortions will be quite large and normal the work of the amplifier when trying to remove the specified power for a long time. Amplifier power is carried out from an unstabilized bipolar source, the amplifier efficiency is 65-70% at best, all the rest of the power is dissipated in the form of unnecessary heat on the output transistors. The assembly of the amplifier begins with the manufacture of the printed circuit board, after etching and drilling the holes for the components, it is imperative to tin all the tracks on the board, additionally it would not hurt to strengthen the power supply tracks with an extra layer of tin. We do the assembly with the installation of small components - resistors, then low-power transistors and capacitors. At the end, we install the largest components - the final stage transistors and electrolytes. Pay attention to the variable resistor that regulates the quiescent current of the output stage, in the diagram it is designated X1 - 3.3kΩ. Some versions have a 1 kΩ resistor. This resistor is highly recommended to use a multiturn resistor, for the most accurate setting of the quiescent current. In this case, the resistor initially, before installation, must be screwed in the larger direction (to the maximum resistance). Let's take a look at the list of required components for assembling the specified circuit.

The costs of components are not small, it will cost around $ 40, taking into account all the subtleties, of course, without a power supply. If you want to use a network transformer to power such a monster, most likely you will have to fork out another $ 20-30, because taking into account the amplifier's efficiency, you will need a network transformer with a power of 400-500 watts. The amplifier consists of from several main nodes, in theory, the same schematic lin is known to our grandfathers. The sound initially enters the double differential stage, in fact, this is where the initial sound is formed. All, all subsequent stages are voltage and current amplifiers. The output stage is a simple current amplifier, in our case, two pairs of powerful switches 2SC5200 / 2SA1943 with a dissipation power of 150 watts are involved. The pre-output stage is a voltage amplifier, and the previous helmet, built on VT5 / VT6 keys, is a current amplifier. In general, the stages that are current amplifiers should overheat quite a lot and need cooling. Transistor BD139 (full analogue of KT315G) is a regulating transistor for the quiescent current of the output stage. Resistor R18 (47Ω) plays an important role in the circuit. The audio signal for exciting the transistors of the output stage is removed from this resistor. The amplifier circuit itself is push-pull, which means that the output (and everything else) transistors open at a certain half-wave of the sine, amplifying only the lower or upper half-cycle. Power supply of diffcascades in any self-respecting amplifier, it is supplied stabilized, or it is stabilized directly on the amplifier board, as in the case of the Lanzar. In the circuit, you can see two Zener diodes with a stabilization voltage of 15 Volts. These zener diodes can be taken with a power of 1-1.5 watts, you can take any (including domestic) Before assembly, carefully check all components for proper operation, even if the latter are completely new. Particular attention should be paid to transistors and powerful resistors that are in the power supply circuit of transistors. The rating of emitter resistors 5 watts 0.33 Ohm can deviate from 0.22 to 0.47 Ohm, I do not advise anymore, just increase the heating on the resistor. After the end of the amplifier Before starting, I advise you to check the installation several times, the location of the components, the bloopers from the installation side. If you are sure that you did not overdo it with the ratings, all the keys and capacitors are soldered correctly, you can move on. VT5 / VT6 - we install it on the heat sink, because of their mode of operation, there is a fairly strong overheating. At the same time, in the case of using a common heat sink for the indicated keys, do not forget to insulate them with mica gaskets and plastic washers, the same is the case for other transistors (except for low-power keys of differential stages. After installation, we take a multimeter and set it to the diode dialing mode. We put one of the shuops on the heat sink, with the second, we touch the terminals of all keys in turn, checking the closure of the keys with the heat sink, if everything is correct, then there should be no short circuits. Resistors R3 / R4 - play a very important role. They are designed to limit the supply of differential stages and are selected based on the supply voltage.

These resistors must be taken with a power of 1-2 watts. Then we carefully connect the power buses and start the amplifier, initially we close the input wire to the midpoint of the power supply (to ground). After starting, we wait a minute, then turn off the amplifier. we check the components for heat dissipation. Initially I advise run the amplifier through a bipolar network power supply unit of 30 volts (in the shoulder) while through a series-connected incandescent lamp of 40-100 watts. At the moment of connecting to the 220 Volt network, the lamp should briefly light up and go out, if it glows all the time, then disconnect and check everything that after the transformer the rectifier unit, capacitors, amplifier) Well, if everything is fine, then we disconnect the amplifier input from the ground and start the amplifier again, not forgetting to connect the dynamic head. If everything is ok, then there should be a small click from the acoustics. Further, without turning off the amplifier, we touch the input wire with our finger, the head should roar, if everything is so, then congratulations! the amplifier is working! But that doesn't mean that everything is ready and you can enjoy, everything is just beginning! Then we connect the audio signal and start the amplifier at about 40% of the maximum volume, those who do not regret the acoustics can turn it on to the maximum. It is advisable to start with modern music, not classics and enjoy 15 minutes. As soon as the heat sink is warm, we begin the second stage - setting the quiescent current of the output stage. For this, the diagram provides a 3.3kOhm variable switch, which was mentioned earlier. Setting the quiescent current according to the photo After adjusting the quiescent current, we proceed to the next part - measuring the output power of our amplifier, but this step is not necessary. Take off output power it is necessary under a sinusoidal signal of 1 kHz into a load of 4 ohms. A resistor immersed in water or resistor assembly with a resistance of 4 ohms must be used as a constant load. The resistor should have a power of 10-30 watts, preferably with as little inductance as possible. At this, the assembly and tuning process has come to its logical end. Printed circuit board viz our lanzar in the attachment, you can download and safely collect, it has been checked repeatedly (more precisely, more than 10 times). It remains only to decide - where you will use the amplifier, at home or in the car. In the case of the latter, most likely you will need a powerful voltage converter, which we have repeatedly talked about on the pages of the site. | |

Last summer, a car audio complex was created, but a year has passed since then and it's time for a change. To begin with, I will explain the essence of the idea. It was conceived to assemble an amplifying device for Hi-Fi discharge for work in a car. The requirements for the amplifier were as follows: a powerful channel of 250-350 watts for powering the subwoofer, two channels for powering the rear acoustics, and 8 channels for powering low-power front heads, but all the selected amplifiers had to be Hi-Fi. To implement such a large-scale project, I needed finances, nerves and a lot of time that I had.

Subwoofer amplifier

Rear speaker amplifier

Front speaker amplifier

PRINTED CIRCUIT BOARD

I did not think about the board for a long time, all the boards of individual blocks were available, it was only necessary to transfer all the templates to the foil-clad fiberglass and etch. PCB and schematic files can be found here. The templates were applied to the general board after a short calculation. For this process, I used the well-known LUT method, each template was ironed for 90 seconds, it must be ironed carefully so that the toner firmly adheres to the foil surface of the PCB and does not peel off when the paper is removed.

Next, let the PCB cool for 5-10 minutes, then carefully remove the paper. First, you need to put the board in a vessel with water and wait a couple of minutes, then carefully remove the paper. I did not find any etching reagents in the town, so I had to go for an alternative. An alternative solution consists of three main components - hydrogen peroxide, citric acid and sodium chloride ... On my board, in general, 12 bottles of hydrogen peroxide were spent (3% hydrogen peroxide solution, each bottle of 100 mg) - purchased at the pharmacy 12 packs of citric acid (pack - 40 mg) - purchased at the grocery store 9 teaspoons of table salt - stolen from the kitchen of his own home. All components are mixed until the salt and citric acid are completely dissolved.

Due to the large size of the board, difficulties arose with the vessel in which the etching was planned. Here, too, I decided to go for an alternative. A plastic bag was purchased in the store, which I placed in a box from some kind of player, the board fits perfectly into such a "vessel". He poured the solution and put the whole thing in the sun. The whole etching process lasted no more than an hour. Quite a violent reaction, so you need to carry out in clean air. Next, you need to wipe off the toner. To do this, use clean (or not so) rags and acetone. The finished board must be thoroughly washed with warm water, then dried with a hairdryer.

Another problem is the disposal of the solution, I acted in a barbaric way, pouring all the solution into the sewer, when you do the same, make sure that no one sees, otherwise ecologists will rush in, in my case this problem did not arise, since I myself am an ecologist (lol) ... Then you need to start drilling holes, and here there are a lot of them. He drilled half of the holes with a 3-kg drill, then a mini-drill with all the amenities was bought specifically for this venture at an ebay auction. In the process of drilling, I used 0.8mm drills for small components (resistors, capacitors, microcircuits, etc.), 1mm drills for larger ones (output transistors of amplifiers, power diodes) and 5mm drills for the outputs of the windings of pulse transformers.

The already drilled board needs to be tinned. To do this, you need a soldering iron for a hundred watts, pine rosin, and of course tin. I advise you to wear a mask during this process, the smoke from rosin is not toxic, but a whole cloud of smoke forms here, it is quite difficult to breathe under such conditions. The glossy tin layer gives the PCB a beautiful appearance and keeps the copper tracks from oxidizing. Only after the completion of this process we have a completely finished printed circuit board, and now we can proceed with the installation ...

We will start assembling PCB parts for our home amplifier from a power source, more precisely two sources, since two power supplies are required. Of course, we do not use power transformers on iron, but switching power supplies.

INVERTER 1

This inverter is only intended to power the subwoofer amplifier in a Lanzar circuit. Output voltage +/- 65 Volts. The inverter does not have output voltage stabilization, but despite this, it did not observe serious voltage surges. The inverter was built according to the classic push-pull scheme using a PWM controller on a microcircuit TL494... The transformer was wound on two rings of 3000NM brand (Eugene, thanks for helping out and sending rings from the other end of the world), the dimensions of the rings are 45 * 28 * 8. If possible, then use ferrite grade 2000NM, with it there are less losses in the transformer. I didn't glue the rings, I just wrapped them with transparent tape. I did not round off the edges of the ring, just before winding the core wrapped with a strip of fiberglass in two layers. Fiberglass is not afraid of overheating and provides a fairly good insulation of the windings, although in such industrial-type inverters they never isolate the windings from each other, since the voltage is not so high.

The winding was done with two completely identical tires, each of the tires consists of 12 strands of wire with a diameter of 0.7 mm. Before winding, we take the control wire, they will find out how long the bus is needed. The control wire can be any, of any cross-section (for convenience, choose a diameter of 0.3-1 mm), So, we take the control wire and wind 5 turns on the ring, stretching the turns evenly throughout the ring. Now we unwind the winding by measuring the length, let's say the length of the wire is 20 cm, therefore, to wind the main winding, the wire must be taken with a margin of 5-7 cm, i.e. 25-27 cm, of course, the length is not accurate and gave only as an example. Now let's move on. Since our primary (power) winding consists of two completely similar arms, we need 24 cores of 0.7 mm wire of the same length. Next, you need to assemble tires from 12 cores, twist the ends of the cores and proceed to the winding process.

Different sources cite different winding technologies, this method differs in that it allows you to get the most equivalent windings. We do the winding with two tires at once, it is advisable to use a tourniquet for convenience, but I wound it without it. As carefully as possible, we wind 5 turns around the entire ring, as a result we get 4 taps. For the durability of the turns, we insulate the winding, test insulation can be any - scotch tape, electrical tape, threads, etc., as long as the winding holds, if you are sure of the correct winding, then you can put the final insulation (in my case, again fiberglass). Now you need to phase the windings by connecting the beginning of the first half-winding (shoulder) to the end of the second, or vice versa, the beginning of the second, to the end of the first. The places where the windings are joined is a tap from the middle, a power plus 12 Volts is supplied to it according to the scheme. The secondary winding is wound and phased according to the same principle as the primary. The winding consists of 2x24 turns, wound with two tires. Each busbar consists of 5 cores of 0.7 mm wire.

Diode rectifier is assembled from 4 series diodes KD213A... These are pulse diodes with a reverse voltage of up to 200 Volts, they feel great at frequencies of 50-80 kHz (although they can operate at frequencies up to 100 kHz), and the maximum allowable current of 10 Amperes is what you need. V additional cooling diodes do not need, although heat may be generated during operation.

The chokes in the output circuit are ready-made, from computer power supplies. Chokes are wound on a ferrite core (length 1.5-2 cm, diameter 6 mm). The winding contains 5-6 turns, wound with a wire of 2-2.5 mm, for convenience, you can wind it with several strands of a thinner wire. I took smoothing electrolytes with a voltage of 100 Volts 1000 μF, they work with a large margin. As a result, there are 4 such capacitors on the inverter board in the shoulder, two more similar ones are on the board amplifier Lanzar, i.e. the total capacity of the filters in the arm is 5000 uF. Before and after the chokes there are film capacitors with a voltage of 100 Volts, their capacity is not particularly critical and can be in the region of 0.1-1 μF.

STARTING THE FIRST PSU INVERTER

Before starting the inverter, we carefully check the correct installation. Low-power transistors BC556 / 557 can be replaced with a domestic analogue of KT3107, BC546 for KT3102 or any others with similar parameters. Field switches during operation without an output load should not heat up, and with a load, the heating of the arms should be uniform. The last stage is heat dissipation. Field effect transistors in my case, they are reinforced with a heat sink from computer unit power supply, through mica gaskets and insulating washers.

The scheme implements a remote control (REM), i.e. the main, power plus and minus are always connected to the amplifier, and in order for the circuit to start up, a plus is applied to the REM point, the BC546 transistor opens and power is supplied to the generator and the operating cycle of the inverter begins. Plus, the remote can be supplied from the car radio, or you can adapt a small toggle switch in the car, which can be used to turn the amplifier on and off.

If you have problems ...

Problem. It so happens that the first time they are turned on, field workers fail.

Cause and elimination ... Incorrectly phased primary winding or defective transistors. If you are sure of the correct installation and the health of all components, then most likely the primary winding of the transformer is incorrectly phased. To do this, we turn off the secondary circuit, that is, the load that is connected to the secondary winding and start the transformer again (often, problems can arise on the secondary circuits), if everything is the same, then we check the transistors for serviceability, they will most likely be "killed", replace and we phase the transformer correctly.

Problem. When turned on, one of the pairs of transistors overheats, the second pair is cold.

Cause and elimination ... First, we check the presence of rectangular pulses at 9 and 10 pins of the microcircuit, if everything is ok, then we check the elimination of diodes and low-power transistors, such a problem arises for two reasons - incorrect connection of low-power transistors of the driver or unequal arms of the primary winding.

INVERTER 2

The circuit and printed circuit board of the second inverter is completely similar to the first. Output voltage for supplying channels OM is 2x55 Volts (+/- 55V). The secondary winding this time is wound with 6 cores of 0.8 mm wire and consists of 2x28 Turns, wound using the same technology as in the case of the first inverter.

Make sure that the primary and secondary windings are always wound IN THE SAME DIRECTION!

Another secondary block is designed to power the amplifier unit on LM1875 microcircuits. The winding consists of 2x8 turns, wound with 4 cores of 0.8 mm wire. After assembling the inverter, we carefully check the installation for errors, if there are none, then we take up the multimeter and check the secondary circuits for short circuits.

FIRST START-UP

The first start-up of the inverter should be done from a laboratory power supply unit with short-circuit protection, while at the time of start-up, the protection may work erroneously if the unit is low-power, in my case a converted power supply unit with a current of 3.5 A was used. The idle current of the inverter is 170-280 mA, depending on the correct calculation of the transformer, the operating frequency of the generator and the type of field switches, the snubber resistor plays a significant role, in my case I had to play a little with it in order to reduce the consumption of the circuit.

During idle, there should be no heat generation on the keys, if there is, then there is a problem with the installation or a non-working component. Before starting, flush the board from fluxes, for this you can use acetone or solvent. And now we proceed to the actual UMZCH unit itself ...

After successfully launching the power supply, we turn to the most interesting part of the design - the audio power amplifier unit. Including a low-pass filter for a subwoofer and a stabilization module.

LANZAR SUBWOOFER AMPLIFIER

What can I say about one of the most repeatable power amplifier circuits - the Lanzar circuit was developed back in the 70s of the last century. On a modern high-precision rudimentary base, Lanzar just sounded even better. In theory, the circuit is excellent for wideband acoustics, distortion at half the volume only 0.04%- full-fledged Hi-fi.

The output stage of the amplifier is built on a pair 2SA1943 and 2SC5200, all stages are assembled on complementary pairs as close in parameters as possible, the amplifier is built entirely on a symmetrical basis. The amplifier has a rated output power of 230-280 watts, but much more can be removed by increasing the input supply voltage. The values of the limiting resistors of the differential stages are selected based on the input voltage. Below is a table.

Power supply ± 70 V - 3.3 kOhm ... 3.9 kOhm

Power supply ± 60 V - 2.7 kOhm ... 3.3 kOhm

Power supply ± 50 V - 2.2 kOhm ... 2.7 kOhm

Power supply ± 40 V - 1.5 kOhm ... 2.2 kOhm

Power supply ± 30 V - 1.0 kOhm ... 1.5 kOhm

These resistors are selected with a power of 1-2 watts, during operation, heat generation may be observed on them.

The regulating transistor was replaced with a domestic one KT815, at that moment there was no other at hand. It is designed to regulate the quiescent current of the output stages, does not overheat during operation, but is attached to a common heat sink with the output stage transistors.

It is advisable to start the circuit for the first time from the mains power supply, in series with the mains winding of the transformer, connect an incandescent lamp of 100-150 watts, if there are problems, then burn a minimum of parts. In general, the Lanzar circuit is not critical to installation and components, I tried it even with a wide range of components used, using domestic radio components - the circuit shows high parameters even in this case. The Lanzar circuit diagram has two main versions - on bipolar transistors and using field switches in the penultimate stage, in my case first version.

The second pre-exit stage works in a clean classroom " A", therefore, during operation, the transistors overheat. The transistors of this stage must be installed on a heat sink, preferably a common one, do not forget about the insulation - mica plates and insulating washers for screws.

A properly assembled circuit starts up without any problems. We do the first launch with EARTH-SHORTED ENTRANCE , i.e. the input of the amplifier is connected to the midpoint from the power supply. If nothing explodes after launch, you can disconnect the input from the ground. Then we connect the load - the speaker and turn on the amplifier. In order to make sure that the amplifier is working, just touch the bare input wire. If a kind of roar appears in the head, then the amplifier is working! Then you can strengthen all the power parts on the heat sinks and apply an audio signal to the amplifier input. After 15-20 minutes of operation at 30-50% of the maximum volume, you need to adjust the quiescent current. The photo shows everything in detail; it is advisable to use a digital multimeter as a voltage indicator.

Amplifier output power measurement

How to set the quiescent current

LPF AND STABILIZATION BLOCK

The low-pass filter and adder is built on two microcircuits. It is designed for smooth adjustment of phase, volume and frequency. The adder is designed to add the signals of both channels to obtain a more powerful signal. In high-power industrial auto-amplifiers, just this principle of filtering and summing the signal is used, but the adder can, if desired, be excluded from the circuit and only a low-pass filter can be dispensed with. The filter cuts off all frequencies, leaving only a limit in the range of 35-150 Hz.

Phase adjustment allows the subwoofer to match the speaker systems, in some cases it is also excluded. This unit is powered by a stabilized +/- 15 Volt bipolar voltage source. Power can be provided using an additional secondary winding, or a bipolar voltage regulator can be used to lower the voltage from the main winding. For this, a bipolar stabilizer is assembled. Initially, the voltage is reduced by zener diodes, then amplified by bipolar transistors and fed to linear voltage regulators of the 7815 and 7915 types. A stable voltage is formed at the output of the stabilizer. bipolar nutrition, which feeds the adder unit and the low-pass filter.

Stabilizers and transistors can get warm, but this is quite normal, if desired, they can be attached to heat sinks, but in my case there is active cooling by a cooler, so heat sinks were not useful, besides, heat dissipation is within normal limits, since the low-pass filter itself consumes very little.

BREAKING THE MICROSCIRCUITS

Slap in the face of mikruham is not the simplest, but high-quality bass power amplifier. The amplifier is capable of developing a maximum output power of 130 watts and operates over a fairly wide input voltage range. The output stage of the amplifier is built on a pair 2sa1943 2sc5200 and works in the mode AB... This version, which was developed by the author this year, is below its main parameters.

Supply voltage range = +/- 20V ... +/- 60V

Nominal supply voltage (100W, 4 Ohm) = +/- 36V

Nominal supply voltage (100W, 8 Ohm) = +/- 48V

With power, everything is clear, but what about the distortion?

THD + N (at Pout<=60Вт, 20кГц) <= 0,0009%

THD + N (at maximum output power, 1kHz) = 0.003%

THD + N (at maximum output power, 20kHz) = 0.008%

The parts used in this module are trimmer resistors, low and medium power transistors:

HERE VIDEO

Not bad at all, almost hi-end! In fact, if you focus only on SOI, then this amplifier is a full-fledged HI-END, but for the high-end this is not enough, so it was attributed to the old and good category hi-fi. Although the amplifier develops only 100 watts, it is an order of magnitude more complicated than similar schemes, but the assembly itself will not be difficult if all the components are present. I do not advise rejecting the nominal values of the scheme - my experience confirms this.

Low-power transistors may overheat during operation, but you should not worry - this is their normal mode of operation. The output stage, as already mentioned, works in class AB, therefore, a huge amount of heat will be released, which must be removed. In my case, they are reinforced with a common heat sink, which is more than enough, but just in case, there is also active cooling.

After assembly, the first run of the circuit is waiting for us. To do this, I advise you to read the launch and configuration of Lanzar again - everything is done in exactly the same way. The first launch is done with the input shorted to the ground, if everything is OK, then we open the input and give a sound signal. By that time, all the power components must be reinforced with a heat sink, otherwise, while admiring the music, you may not notice how the keys of the output stage smoke - each of them costs a lot.

We finally made our home audio system amplifier sound decent, tested its performance, and evaluated the sound quality of the main channel. It's time to add a protection module against accidental circuits to it, so that all work does not go to the forest, due to inevitable accidents during its operation. We will also collect the rest of the low-power ULF channels to connect the rear speakers.

PROTECTION OF AS UMZCH

Initially conceived to use a protection circuit against BRIG , but then reading reviews about triac protection I wanted to try it. The protection blocks were made at the very end, then it was tight with finances, and the triacs and other components of the circuit turned out to be quite expensive for us, so we returned to relay protection.

As a result, three protection units were assembled, one of them for the subwoofer amplifier, and the other two for the OM channels.

You can find a large number of protection block schemes on the network, but I have tried this scheme many times. In the presence of a constant voltage at the output (above the permissible), the protection instantly triggers, saving the dynamic head. After power is applied, the relay closes, and when the circuit is triggered, it should open. The protection turns on the head with a slight delay - this, in turn, is an additional insurance and the click after turning on is almost inaudible.

The components of the protection unit may deviate from the specified, the main transistor can be replaced with our KT815G, used high voltage transistors MJE13003- I have them in bulk, in addition, they are quite powerful and do not overheat during operation, so they do not need a heat sink. Low-power transistors can be replaced by S9014, 9018, 9012, even on KT315, the best option is 2N5551... Relay for 7-10 Amperes, you can pick up any relay for 12 or 24 Volts, in my case 12 Volts.

Protection blocks for OM channels are installed near the transformer of the second inverter, the whole thing works quite clearly, at maximum volume the protection can work (falsely) extremely rarely.

LOW POWER AMPLIFIERS

It took a long time to decide which amplifier to use for low-power speaker systems. As a cheap option, I first decided to use microcircuits TDA2030, then I thought that 18 watts per channel was not enough and switched to TDA2050- a powerful analogue of 32 watts. Then, comparing the sound of the main options, the choice fell on your favorite microcircuit - LM1875, 24 watts and the sound quality is 2-3 orders of magnitude better than that of the first two microcircuits.

I dug in the network for a long time, but I could not find a printed circuit board for my needs. Sitting at the computer for several hours, a version was created for a five-channel amplifier on microcircuits LM1875 , the board turned out to be quite compact; the board also has a block of rectifiers and filters. This block was fully assembled in 2 hours - all components were in stock by then.

VIDEO AMPLIFIER

The sound quality of these microcircuits is at a very high level, in the end the discharge Hi-fi, the power output is decent - 24 watts of sine, but in my case the power is increased by increasing the supply voltage to 24 volts, in which case you can get about 30 watts of output power. On the main board of the amplifier, I had a place for a 4-channel amplifier on TDA2030 , but somehow I didn't like it ...

The board for LM is attached to the main ULF board through posts in the form of tubes and bolts. Power for this unit is taken from the second inverter, a separate winding is provided. The rectifier and filter capacitors are located directly on the amplifier board. As rectifier diodes are already traditional KD213A... I did not use chokes to smooth out RF interference, and there is no need to use them, since they are often not installed even in fairly branded car amplifiers. As a heat sink, I used a set of duralumin blanks 200x40x10 mm.

A cooler is also mounted on the board, which simultaneously removes warm air from this unit and blows off the heat sinks of the inverters. We have completely sorted out the electronics of the audio complex - we are moving on to mechanics and plumbing ...

The basis of any radio amateur design is a beautiful comfortable case, especially since it should look decent in a device that takes its rightful place in the living room or in your office.

BODY AND MOUNTING

I suffered with the body for a particularly long time, until one day a stranger came to me. In his hands was a device that looked like an old power amplifier. The man introduced himself and began a conversation. It turned out that he knew me perfectly and brought a little thing he did not need to exchange for an uninterruptible power supply. The uninterruptible power supply did not give him, but persuaded him to sell the device for 400 rubles. Without thinking twice, he agreed. The device is a compressor from the company TESLA , was in quite working condition, but from it I only needed a case, which was just suitable for the amplifying complex.

VIDEO - DIY AMPLIFIER

The transformers were fixed to the board with the help of a particularly strong "moment" glue, additionally pressed them to the board with metal washers (with a rubber gasket so as not to pinch the windings), which had to be painted black so as not to catch the eye. Washers are bolted with 40 mm long and 4 mm diameter bolts.