SAMSUNG LED LED LED LED. Spare parts for household appliances, repair shop, buying in St. Petersburg. After that, I measured the necessary parameters in the power supply, which was mentioned above

On the site you can familiarize yourself with full list spare parts. Here is some of them:

spare parts from televisions;

spare parts from cooking panels ;

Spare parts from refrigerators;

spare parts from washing machines;

You have the opportunity to purchase goods, both in retail and wholesale in St. Petersburg, for workshops we have a system of discounts.

If you doubt your choice, contact your consultant. A whole team of administrators is ready to advise you by tolding about all the advantages of the selected model. They are thoroughly disassembled in the selection and device of any spare part. By contacting the contact phone - the specialist will clearly answer all your questions.

Electronics repair workshop.

Experts will produce full diagnostics The laptop will find out the cause of the computer breakdown and eliminate it. After repair, your technique will serve for a long time and efficiently. To calm customers - we issue a document that provides a guarantee for all types of repair work.

Our workshop will be glad to welcome new customers. Employees of the Cyber \u200b\u200bWorkshop will provide you with high-quality advice on the phone at any time convenient for you. And repair repair technical devices In a convenient way for you in the shortest possible time. We provide a wide range of services to solve problems with your technique.

Working with us - means save your time and money, and eventually obtain the highest quality result with the warranty officially documented period.

Purchase of equipment in SPb - Turn your boot technique in money!

Without such a backlight, no liquid crystal TV can work normally regardless of its brand. We will tell how to make a repair of LED highlighting the TV at home on the example of a device from LG, and what you will need for this.

How to determine what illuminated is broken? Suppose that the fault of the LCD TV is such: turns on from the remote control, but the screen does not shine (if your TV does not turn on even from the console - read О). When the display is directed light from flashlight (i.e., forced backlighting), the image manifests itself. The verdict - the ice driver or similar backlight does not work, may be due to the fact that the special rules with soldered LEDs are blown. You need to disassemble the TV and visually inspect the details in troubleshooting.

Attention! You can open the TV LCD housing only if you have skills to work with complex devices and a small experience, otherwise it is better not to risk.

Remove the back cover Any TV brand LG is simple, just to do everything neatly and without a rush: we disconnect the stands of the stand and unscrew the mount throughout the perimeter of the product. If the lid is not removed - it means there is a blocking bolt, you should not make an effort, you need to find it and unscrew it.

After removal back cover, Check the output voltage.

If it is normal - check stress Ice backlight Screen itself. The value of its total is 100V, which indicates the presence of a lighting of the LCD TV.

In such TVs, a special LED set with lenses is used, which is installed throughout the screen area to provide clear illumination. To get to them, and repair the LG TV illumination, you must first remove the matrix.

Disassembly of the product

The TV has three main boards - main, t-con and power supply, all of them are clearly visible in the photo.

Removal and disassembly of the matrix With your own hands - the work is very painstaking, one careless movement, and you can buy a new telly, so it is better not to take to repair without experience. Experts identify such highlights when disassembling the matrix:

- it is necessary to prepare place of work and two tables for which laying matrices and scattering films;

- before starting this work, you should thoroughly wash your hands to accidentally not leave the traces of dirty fingers on the filters and the matrix itself - it can harm the image quality afterwards;

- special attention should be paid to decoders - one inaccurate movement can entail a loop break.

Subsequent dismantling is carried out in several stages.

Finding a fault

Now it starts directly repairing the LED TV illumination: for this you need the contour to deduct neatly all latches, remove the frame from the plastic and remove the scattering films to open the LEDs.

W. different models LG TVs will have its own set of backlighting: for LG 32LN541U - these are three rows of 7 LEDs, and for LG 32LB582V - three to 6 pieces.

In all TVs where such a backlight is used, the LEDs are connected in series, so when one of them is bravely, the entire system stops working. If the LED driver is defective, then the voltage is not received by the entire system, and when one of the LEDs burned out, the voltage goes, but all the efforts of the device will light up the system in vain: even give 200 volts, the circuit is open.

As you can see from the photo, the backlight consists of 18 LEDs, when measurements, the voltage without load was 140 V, that is, it accounted for 7.8 V. When we take into account the voltage drop on each bar and the overall load, the output will be like this: in this model are used LEDs on 6 V.

Find a blown LED is not easy: if there is no burning at the place of attachment, then you need to check each element separately.

Replacing LEDs

Replacing the LG TV illumination can cause certain difficulties. Suppose, on the results of the inspection, several faulty LEDs were revealed. It is quite difficult to buy a shift bar - these parts are not supplied to the service centers, you can order them on the manufacturer's website, but it is long and very expensive. So, there is only one way - replace individual diodesAlthough it will not be easy to find them on Radiorenka. Experts assure that you can buy already soldering, but serviceable, after a long search, just that were purchased.

Users should know that all the planks are glued with bilateral Scotcha, Therefore, it is necessary to warm them up with a special soldering hair dryer so that Scotch has departed. For this, the bar is fixed in the holder and heated from the bottom with a hairdryer, tin melted, and the faulty item is removed. It follows exactly the same method so as not to damage the LED.

Important! All lenses at the factory are fixed by the compound, so when they are removed, it is necessary to act very carefully, while each you need to install each other in order to not disturb the initial focus.

Another nuance: LEDs can be cracked, which have a minus playground a bit more than a plus, so you need to trim the contact location to enter the diode. So the deployed LED looks like:

What is damaged a little paint is not trouble. In the same way, the rest of the LEDs are depicting, and lenses stick to superciles. And this is a renovated view of the collected and ready for the further operation of the backlight panel:

As you can see in practice, in the repair of LED backlighting the LG TV matrix there are many specific nuances, and not knowing them, it is impossible to achieve a positive result.

Final work

When the repair of the LED LG TV system was carried out completely, before performing the final assembly, connect the voltage to the straps and checking the glow of all LEDs. If everything is fine, then you collect the TV, performing all operations consistently and with caution, as well as when dismantling.

After completing the backlight brightness, it is better not to remove to a maximum, and limit to 75% - with this mode, the LEDs operate in normal mode and, according to experts, they will serve much longer.

We install the TV to the previous place, turn it on to the network and enjoy the quality: if there are no extraneous spots on the screen on the screen, it means that the repair was performed correctly, in compliance with all the recommendations. And get the maximum of the possibilities from your TV by learning how it is

Most reliable LG TVs 2018

TV LG 22LH450V.

TV LG 49UJ651V.

TV LG OLED55C8.

TV LG 55LJ622V.

TV LG 55UK6100.

One of the most common defects of LED TVs are missing screen illumination.

Visually, this defect looks very simple: "There is no sound - no, but it's not quite so. If you look at the TV screen and additionally shine a flashlight on it, you can see what the action is still on the screen. If so, the defect is most likely failed diode backlight Images. As a rule, if one or two diode burns out, the "brains" of the TV allow you to work the backlight on, but more is already critical and the backlight goes out completely. Some TVs at startup still show the image, and then the screen goes out, and some at once do not show anything. This is caused in different way software setup, as well as the severity of malfunction.

Today we will look at the example of the SAMSUNG UE32F5020AK TV.

Any repair begins with the parsing of the device and each device has its own nuances. In our case, you need to pay attention to the small cap, which must be removed before removing the main cover, because Under it is the connector into which the button control on the TV case is inserted and it must be turned off. After that, we unscrew and remove the main back cover.

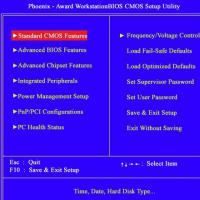

The back lid is removed and we see all the insides of the TV. And this is just Motherboard (Main Board), Power Supply Unit (Power Supply Unit), Speakers, Clay T-con and T-CON SAM (TIME CONTROLLER).

Turn off the loops that run from T-CON card to matrix straps.

Next, proceed to the analysis of the "matrix". It is recommended to approach the removal of the main framework very carefully, as it is very well fixed on the latches. And many masters prefer to use the "shovels" to subscribe the frame and its fill, but in this matter there is one nuance and it is necessary to approach him very responsibly. The name of this nuance "Side Matrix Drivers", in Proslezodia "Petals".

Next, proceed to the analysis of the "matrix". It is recommended to approach the removal of the main framework very carefully, as it is very well fixed on the latches. And many masters prefer to use the "shovels" to subscribe the frame and its fill, but in this matter there is one nuance and it is necessary to approach him very responsibly. The name of this nuance "Side Matrix Drivers", in Proslezodia "Petals".  If you come up with a shovel or any other similar tool, you can hook the petal, or rather the crystal that is on it. As can be seen in the photo, it is located just from the inside of the driver. Unfortunately, if the integrity of the crystal is broken, then a defect will appear in the form of lines and restore the integrity will not be possible. Or you need to change the glass or the matrix assembly or the petal. But the last procedure in the stationary conditions of the service center to implement, unfortunately, is almost impossible. Yes, and the price will be slightly cheaper than the replacement of the matrix assembly (unless of course talk about low-cost TVs).

If you come up with a shovel or any other similar tool, you can hook the petal, or rather the crystal that is on it. As can be seen in the photo, it is located just from the inside of the driver. Unfortunately, if the integrity of the crystal is broken, then a defect will appear in the form of lines and restore the integrity will not be possible. Or you need to change the glass or the matrix assembly or the petal. But the last procedure in the stationary conditions of the service center to implement, unfortunately, is almost impossible. Yes, and the price will be slightly cheaper than the replacement of the matrix assembly (unless of course talk about low-cost TVs).

We removed the frame, did not hooked anything and can continue.

We are convinced that it does not interfere with us, there is no extra objects (tools, instruments), take out the matrix bar, we wear antistatic gloves and remove the glass very carefully. It is impossible to put it anywhere, as the glass is very fragile and it is necessary to maximize the interaction of the glass with something. We lean it to the wall behind the workplace.

Then remove the frame on which glass lay. She is fixed in a circle. Decorate them should not be a problem.

Then remove the frame on which glass lay. She is fixed in a circle. Decorate them should not be a problem.

Remove polarization lists  .

. And so we almost got to diode lines. Remained last pageBut it is fixed by the locks that play two roles. The first role is to hold the main reflector and the second - they do not give to the upper polarization sheets.

And so we almost got to diode lines. Remained last pageBut it is fixed by the locks that play two roles. The first role is to hold the main reflector and the second - they do not give to the upper polarization sheets.

In our TV, it will not be much difficult to remove them. They must be turned and remove. This is done by hand, however, if it does not work with your hand, you can use the tool. The main thing is not to overdo it and do not break them. .

So. Everything is ready for repair. Now you need to identify faulty diodes and replace them.

To identify faulty diodes, we use a special device.

A faulty diode may be either in a short circuit or just burned out. These are two fundamentally different defects, since if the diode burned down and is located, for example, at the very beginning of the line, then with the entire line of all the diodes, except our culprit will light up.  .

.

And if the diode is closed, then the ruler will not burn, because it will not receive feedback To ignite the remaining diodes. In this case, every diode will have to be or nicking separately, or search for working segments. In this photo, the second diode on the left is in a short circuit, and the fourth just burned down.

After finding faulty diodes, removing the rules on which there are those and proceed to replace.

With a faulty diode, we remove the scattering lens and check it again using the instrument.

Make sure that it really does not burn and proceed to his replacement. You can dig and solder both with the help of a soldering iron and with a hair dryer. But in our opinion in easier and better solder with a hair dryer. For this work, we use a soldering station.

We post the bar in such a way that it may be a hairdryer to warm the platform on which the diode is fixed and searched it. Next, we apply a flux and apply a working diode to the site and also sear it back with a hair dryer. It is important not to confuse the polarity of the diode, and it is also recommended to use the same diodes that stand on a specific barbecue, not only by voltage, but also in form. The playground in our case looks like

Very often, televisions with a similar defect come to repair, but after another service, where the absences of suitable diodes are attacked as ababy. Of course, such work does not bring a durable result and it is necessary to redo, and the client pay extra money.

So. The diode is replaced, check again by the device.

.

The next step is the return of the scattering lenses in its place. This is a very serious step, because it depends on it, how the diode will be shining in the composition of the already assembled LCD module.

If the lens attach not exactly in the center, but to move a little to the side, then the dispersion will not be even, and, as a result, on the scattering sheets instead of even light light, the so-called, halisses around the lenses will be visible. And if the lens shifted quite a bit, it is most likely in the image they will not be noticeable or will be, but only on a bright white background, but if they are shifted strongly, then they will be noticeable almost in any picture and any color.

Lenses are replaced. Install the planks in your place, we feed on the TV and check. .

All diodes are lit, the backlight is restored. We start collecting our device back. In the process of collecting, I recommend to turn it on two more times. The first time we put all polarization layers into our places to make sure there are no halo. And also after you put (but do not fix it) glass.

Connected, checked, everything works.

Now the most difficult! The last frame that closes the glass and is the facial frame of our TV. The fact is that the more modern TV, the thinner the framework is used. There are different variations of the framework. Some twisted, others are snapped, but the main essence is one - glass is placed on the frame in the grooves. The grooves are calculated so that the gaps between them and the glass practically does not happen. Thus, if the glass put a little crookedly and missed, and then snap the front frame, the result will be sad. If the glass of the matrix even has a small imperceptible chip, then, alas, the image will be spoiled. Any little damage to the matrix leads to irreversible consequences and watching such TV will already be impossible.

So. TV is assembled, the image appeared. All right.

But on this our repair is not completed. In order for this defect to be repeated, we need to still refine the power supply. The fact is that a high current is supplied to the backlight for a bright glow of diodes, when it is required and, accordingly, the life of the diodes is directly dependent on the current, reduces. We use the practice of reducing current, for the greater life of the diodes. It does not affect the quality of the image, but it affects the increase in the diodes.

In this case, we find a backlight resistor on the power supply. Its parameter is 3.4 Ohm and change it to a larger, or we consistently increase its parameter by another resistor. In our case, we took another resistor per 1.2 ohm and consistently soldered to it.

Now the current is reduced, defective diodes are replaced. The TV is assembled and issued to the owner.

With comparatively inexpensive work and rapid repair date this TV A long time to please the client, and we, in turn, received gratitude and positive feedback.

Hello everyone. In this article I will talk about LED backlighting TV matrix, namely, for what reason the LEDs are burning in the backlight, where they can be bought, and how to prevent them from re-out.

About LED backlighting TV matrix.

The first LCD televisions had a backlight made using fluorescent (CCFL) lamps. This type The backlight worked very well, but the brightness of the glow left much to be desired. Such TVs were inferior as a plasma panel as an image, but won on their dimensions, and weight.

As science does not stand still, instead CCFL lamps LEDs that their bright glow and low current consumption have begun to be used in the development of LCD televisions. Of course, the matrices themselves, too, during this time, have improved much in quality and color, so that the dull glow of CCFL lamps could not fully pass the picture that manufacturers would like to see.

The reasons for the failure of the LED highlighting TVs.

Since I often repair TVs, and on my old site more than once described the repair process, then for myself I can select several basic causes of failure of LED LEDs.

The first reason - This defects the manufacturers themselves. Very often, based on my practice, the manufacturers themselves configure the backlight driver in such a way that there are current on the line of LEDs, more laid, as a result of which the LEDs are overheated, and fail.

The second reason - This is a marriage of the LEDs themselves. It happens that the disassembly matrix finds only one faulty diode. At the same time, the current that goes on the matrix is \u200b\u200bwithin the normal range, and all other LEDs are in excellent condition.

Third reason - Directly related to the first. Some owners love to watch TVs on the maximum brightness (the backlight is on 100%). Since the manufacturers of some TVs specifically overestimate the current that enters the LEDs, viewing in this mode does not pour the life of the TV backlight. I recommend not to increase the backlight level of more than 70%. In this mode, your TV will work much longer.

What LEDs I use to repair LED backlighting TVs and where I buy them.

All LEDs I buy on AliExpress in proven sellers. How to search and replace LEDs on the planks, I will show in subsequent articles, and now I will lay out a list of the most popular LEDs that are used in the repairs of the backlight.

| Photo | Name | Link for purchase |

| LEDs 2 W 6 volts on lg Size 3535 (large playground anode (+)) | ||

|

LEDs 6 volts on lg 1 W Size 7030 | |

|

LEDs 3 volts on LG 0.5 W Size 7020 | |

|

LEDs 3 volts on LG size 3528 (large playground anode (+)) | |

|

LEDs 3 volts on Samsung 1 W Size 3537 | |

|

3 volts LEDs on Samsung Size 7032 | |

|

LEDs 3 volts on samsung 0.5 W Size 5630 | |

|

LEDs 3535 2WAT 6 volts on LG (large cathode (-)) | Glue for lenses and touchscrees. When buying on Chinese sites, do not forget to use Cashback. What cachekkom I use, described in. The best course on the repair of televisions, thanks to which I learned to repair the TVs are located In further articles, I will describe the entire process of replacing LEDs on LED backlight planets. Thank you all for your attention and good luck in repairs and homemade. POST Views: 1 093 |

Hello everyone!

Today we will be repair LCD TV Samsung , more precisely, we will troubleshoot the fault that has arisen in lED backlight This apparatus.

So, in repair entered led. television Samsung, model UE42F5500AK, with lED backlight .

According to the client's words, the TV screen first darkened at the top, and then at all went out. At the same time, all other functions worked properly, i.e. There was sound, channels switched, etc. Also, when you will enjoy a flashlight on the matrix, the image can be seen.

Well, let's start repair LCD TV .

With these symptoms, you can assume two options - or the power supply has failed (no power is powered by lED backlight ), Or the backlight itself failed (LEDs burned out, the passage of power on the tracks in the backlight planets) was disturbed).

In the first case, you need to check the power circuit from secondary winding transformer to the contactor who goes on the backlight itself as well lED Driverconsisting of SLC5012M PWM controller and two keys that are collected on the field N-channel transistors D3N40. Also, in this case, you need to check the power to the PWM controller itself.

In the second case, you will need to remove the matrix to get to lED backlight , and then, using a multimeter, make the necessary measurements to identify the cause of the fault: check the tracks in the backlight plars and, if they are working, check the LEDs of this backlight.

FROM possible reasons We have decided, now proceed to the specific diagnostics of the device.

So, the TV was "opened".

After that, I measured the necessary parameters in the power supply, which was mentioned above.

It turned out that the power supply is in working condition, even the power was powered to the TV backlight (with the apparatus turned on).

Based on this, it was concluded that the backlight of the TV matrix was faulty. To get to it, it was necessary to remove the matrix and diffusers from the hull, which was done.

Next, the tracks were tested, which were good.

After that, I began to check the LEDs, which were 98 pieces (7 planks of 14 LEDs in each).

Checked by a conventional digital multimeter on the "transverse" scale of diodes.

At the placters there were contacts to which the contact probe could be connected to check the LEDs. Connecting the probe multimeter to contacts on the bar, observe the polarity, since these LEDs have a plus and minus. For proper connection and a working LED, the LED will glow. If the connection is correct, and the LED does not shine, then this LED is faulty. Also, if the LED shows short circuit, In this case, the diode is faulty.

In order not to check all the LEDs, you can apply to the planks constant pressure 25 ... 35V. Plank with serviceable LEDs, in this case, will work, i.e. All LEDs will be lit on this bar. The bar on which the LEDs will not be lit, you need to subjected to a more thorough check, measuring each LED separately.

In general, having done the above manipulation of verification lED backlight Two faulty LEDs located on the first and fifth placas were discovered.

So, the reason for the inoperability of the TV was revealed, now it remains to produce replace the backlight , namely, the two failed LEDs.

This is not so simple, since there are no such LEDs on sale (at least with us). In this regard, it was decided to establish LEDs with a donor plank. Donor planks can be found in workshops or service centersIf the dirty master falls. In my case, the dirty master was found.

You can replace the LED in two ways - to fall out defective and serviceable LEDs and instead of the faulty install the serviceable one. To fall such a LED, you need to remove the reflector and soldering hair dryer to warm up the bar from the bottom, on the site of the dropped LED before the moment when the LED will freely "stretch" from its place. It is necessary to do it very carefully that the LED is not paid, as they are very gentle. And to get a diode, you need to use a soldering iron with a thin stress (do not forget about the polarity of LEDs).

Causes of why Flash Player does not work, and troubleshooting

Causes of why Flash Player does not work, and troubleshooting The laptop itself turns off, what to do?

The laptop itself turns off, what to do? HP Pavilion DV6: Characteristics and Reviews

HP Pavilion DV6: Characteristics and Reviews Format representation of a floating point numbers How negative numbers are stored in the computer's memory

Format representation of a floating point numbers How negative numbers are stored in the computer's memory Computer fries and does not turn on what to do?

Computer fries and does not turn on what to do? Why does not work mouse on a laptop or mouse?

Why does not work mouse on a laptop or mouse? How to increase or decrease the scale of the page (font) in classmates?

How to increase or decrease the scale of the page (font) in classmates?