Driver in LED lamps. Drivers for LEDs: what it is for what they need. What are the main characteristics of the LED - drivers

Recently, consumers are increasingly interested in LED lighting. The popularity of LED lamps is quite substantiated - the new technology of lighting does not allocate ultraviolet studies, economical, and the life of such lamps is more than 10 years. In addition, with LED elements in domestic and office interiors, it's easy to create original light textures on the street.

If you decide to purchase such devices for your home or office, then you should know that they are very demanding to the parameters of the power grid. For optimal lighting operation, you will need a LED driver. Since the construction market is filled with devices of both different quality and pricing policies, before purchasing lED devices And the power supply to them, it will not be superfluous with the main advice that specialists give in this matter.

To begin with, consider what such a device is needed as a driver.

What is the purpose of the drivers?

The driver (power supply) is a device that performs the functions of the current stabilization flowing through the LED circuit, and is responsible for the device you purchased to work out the number of hours. When selecting a power unit, it is necessary to begin to thoroughly examine its output characteristics, among which the current, voltage, power, efficiency (efficiency), as well as the degree of it to protect the effect of external factors.

For example, the brightness of the LED depends on the passage characteristics of the current. The digital stress designation reflects the range in which the driver functions with possible voltage jumps. And of course, the higher the efficiency, the more effectively the device will work, and its life will be more.

Where are the LED drivers apply?

The electronic device - the driver - usually eats from the electrical network at 220V, but designed to work and with very low voltage B10, 12 and 24V. The range of working output voltage, in most cases, is from 3B to several dozen volts. For example, you need to connect seven LEDs with voltage 3B. In this case, the driver is required with an output voltage from 9 to 24V, which is designed for 780 mA. Please note that despite the versatility, such a driver will have a small efficiency, if you give it a minimum load.

If you need to install lighting in a car, insert a lamp into a bike head, a motorcycle, one or two small street lamps or a manual flashlight, nutrition from 9 to 36V will be quite enough.

LED - Powerfuls will need to choose if you intend to connect the LED system consisting of three or more devices, on the street, chose it to design your interior, or you have desktop office lamps that work at least 8 hours a day .

How does the driver work?

As we have already told, LED - the driver acts as a source of current. The voltage source creates some voltage at its output, ideally independent of the load.

For example, connect to a voltage of 12 to the resistor 40 Ohm. Through it will go the current of 300mma.

Now we will turn on two resistors at once. The total current will be already 600mA.

The power supply supports the specified current at its output. Voltage can change. Connect the same resistor 40 to the 300mA driver.

The power supply will create a 12V voltage drop on the resistor.

If you connect parallel to two resistors, the current will also be 300mA, and the voltage will fall twice.

What are the main characteristics LED - Drivers?

When selecting the driver, be sure to pay attention to parameters such as output voltage, power consumed power (current).

- the voltage at the outlet depends on the voltage drop on the LED; the number of LEDs; From the method of connection.

- The current at the output of the power supply is determined by the characteristics of the LED and depends on their power and brightness, quantity and color solutions.

Let us dwell on the color characteristics of LED - lamps. From this, the load power depends on the word. For example, the average power consumption of a red LED varies within 740 MW. In green, the average power will be about 1.20 W. Based on this data, you can calculate in advance which power you will need the driver.

P \u003d PLED X N

where PLED is the power of LED, N is the number of connected diodes.

Another important rule. D.la stable work Power supply Power supply must be at least 25%. That is, the following ratio should be performed:

PMAX ≥ (1.2 ... 1.3) XP

where Pmax is the maximum power supply power.

How to connect LED-LED?

Connect LEDs in several ways.

The first method is a consistent introduction. Here you will need a driver with voltage of 12V and a current of 300mA. With this method, the LEDs in the lamp or on the tape are in the same way bright, but if you decide to connect a larger number of LEDs, you will need a driver with a very large voltage.

The second method is a parallel connection. We will fit the power supply to 6B, and the current will be consumed approximately twice as much as with a sequential connection. There is a disadvantage - one chain can shine brighter than the other.

Consecutive-parallel compound - occurs in spotlights and other powerful luminaires, and from constant, and from alternating voltage.

Fourth way - the driver is connected sequentially two. It is the least preferable.

There is also a hybrid option. He combined the dignity from the serial and parallel connection of the LEDs.

Specialists advise the driver to choose before you buy LEDs, and it is also desirable to pre-determine the circuit of their connection. So the power supply will work to work more effectively.

Linear and impulse drivers. What are their principles of work?

Today for LED lamps and tapes produce linear and pulse drivers.

W. linear output The current generator serves that provides voltage stabilization without creating electromagnetic interference. Such drivers are easy to use and not expensive, but the low efficiency limits their scope.

Pulse drivers, on the contrary, have a high efficiency (about 96%), and even compact. The driver with such characteristics is preferable to use for portable lighting devices, which allows you to increase the power supply time. But there is a minus - due to the high level of electromagnetic interference, it is less attractive.

Do you need a LED driver for 220v?

To turn on the 220V network, linear and pulse drivers are available. In this case, if the power supplies have galvanic junction (power transmission or signal between electrical circuits without electrical contact between it), they demonstrate a high efficiency, reliability and safety in operation.

Without electroplating, the power supply will cost you cheaper, but it will not be so reliable, it will take care when connecting due to the danger of impact shock.

When selecting power parameters, experts recommend to stop their choice on LED drivers with a power exceeding the required minimum by 25%. Such a power supply will not give an electronic device and a supply device to quickly fail.

Should I buy Chinese drivers?

Made in China - Today you can meet hundreds of drivers of various characteristics produced in China. What do they imagine? These are mainly devices with a pulse source of current by 350-700mA. The low price and the presence of galvanic junction allow such drivers to be in demand from buyers. But there are disadvantages of the Chinese assembly. Often they do not have the case, the use of cheap elements reduces the driver's reliability, and there is also no protection against overheating and oscillations in the power grid.

Chinese drivers, like many products manufactured in Middle Kingdom, are short-lived. Therefore, if you want to set a high-quality lighting system that will serve you for one year, it is best to buy a transducer for LEDs from a proven manufacturer.

What is the service life of the LED driver?

Drivers, like any electronics, have their own service life. The warranty service life of the LED - driver is 30,000 hours. But do not forget that the operation time of the device will depend on the instability of the network voltage, the level of humidity and temperature drop, the effect on it by external factors.

Incomplete loading driver also reduces the life of the device. For example, if the LED is designed for 200W, and runs on the load 90W, half of its power returns to the electrical network, causing it overload. It provokes frequent power failures and the device can overcome, losing you just a year.

Follow our tips and then you do not have to change the LED devices.

To construct LED lamps, power supplies are constantly required. With a large amount, it is quite possible to establish the driver assembly on your own, but the cost of such drivers is not so low, and the manufacture and soldering of bilateral printed circuit boards with SMD components - the process at home is quite time consuming.

I decided to do the ready driver. I needed an inexpensive driver without a case, preferably with the ability to set up current and dimming.

The scheme redrawn and a little refined

Characteristics without capacitors ~ 0.9V and 8.7% (luminous flux pulsations)

The outlet capacitor is expected to reduce the ripples twice as 0.4V and 4%

But the 10MKF capacitor at the entrance reduces the pulsations of 9 times ~ 0.1V and 1%, however, adding this capacitor significantly reduces PF (power factor)

Both capacitors bring the characteristics of the output ripples to passport ~ 0.05V and 0.6%

So pulsation is defeated using two capacitors from the old power supply.

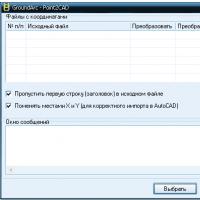

Refinement number 2. Configuring the output current driver

The main purpose of the drivers is to maintain a stable current on LEDs. This driver stably gives 600mA.

Sometimes the driver current wants to change. This is usually made by the selection of a resistor or a capacitor in the feedback circuit. How are these drivers? And why are there three parallel resistor of low resistance R4, R5, R6 installed here?

That's right. They can be set output current. Apparently, all drivers are the same power, but different currents are distinguished by these resistors and output transformer, which gives different stresses.

If you carefully dismantle the resistor at 1.9, we obtain the output current of 430ma, dismantling both resistors 300mA.

You can go and inversely, to take another resistor in parallel, but this driver will produce voltage up to 35V and with a larger current we will get an exception by power, which can lead to the driver output. But 700mA can be squeezed.

So, with the help of the selection of resistors R4, R5 and R6, you can reduce the output current of the driver (or very slightly increase) without changing the number of LEDs in the chain.

Refinement 3. Dimming

On the driver board there are three contacts with the inscription DIMM, which suggests that this driver can control the capacity of LEDs. The same says and datashet on the chip, although typical dimming schemes in them are not given. From the datashet, you can learn information that feeding 7 chips voltage -0.3 - 6B to foot 7, you can get smooth power regulation.

Connecting to DIMM contacts A variable resistor does not lead to anything, in addition, the foot 7 of the driver chip is not connected to anything. So rejection again.

Sweep the resistor on 100K to foot 7 chips

Now feeding a 0-5V voltage between the Earth and resistor we get the current 60-600m

To reduce the minimum dimming current, it is necessary to reduce the resistor. Unfortunately, nothing is written in the datashitis about it, so it will be necessary to select all the components by means. I personally arranged dimming from 60 to 600m.

If you need to organize dimming without external power, then you can take the supply voltage of the driver ~ 15V (2 chips or resistor R7) and apply according to the following scheme.

Well, finally, I give a PHM with D3 Arduino to the dimming entrance.

I am writing the simplest sketch, changing the level of PWM from 0 to the maximum and back:

#Include.

void setup () (

Pinmode (3, Output);

Serial.begin (9600);

AnalogWrite (3.0);

}void loop () (

for (int i \u003d 0; i< 255; i+=10){

AnalogWrite (3, I);

Delay (500);

}

For (int i \u003d 255; i\u003e \u003d 0; i- \u003d 10) (

AnalogWrite (3, I);

Delay (500);

}

}

I get dimming with PWM.

Dimmation using PWM increases the output pulsation by about 10-20% compared with DC control. Maximum ripples are roughly doubled when the driver is installed half from the maximum.

Driver checking on KZ

The current driver must react correctly to a short circuit. But it is better to check the Chinese. I do not like such things. Under the voltage to stick something. But art requires victims. Cut the driver output while working:

The driver normally transfers short circuits and restores its work. Protection against KZ is.

Let's summarize

Pros Driver

- Small dimensions

- Low cost

- Ability to adjust the current

- The possibility of dimming

Minuses

- High weekend pulsations (eliminated by adding capacitors)

- Dimmation input must be unpaved

- Little normal documentation. Incomplete datasheet

- When working, another minus was revealed - interference with the radio in the FM range. It is treated with the installation of the driver to the aluminum case or the housing of the foil or aluminum scotch

Drivers are quite suitable for those who are friends with the soldering iron or for those who are not friendly, but ready to endure the weekend pulsation 3-4%.

useful links

From the cycle - cats are liquid. Timofey - Litres 5-6)))

An integral part of any high-quality lamp or luminaire on LEDs is a driver. With regard to lighting, under the concept of "driver" should be understood by an electronic circuit that converts the input voltage into a stabilized current of a given value. The driver functionality is determined by the width of the input voltage range, the possibility of adjusting the output parameters, susceptibility to differentials in the supply network and efficiency.

From listed functions depend high-quality indicators of the lamp or lamp as a whole, service life and cost. All power sources (IP) for LEDs are conditionally separated on linear and pulsed type converters. Linear IPs may have a current or voltage stabilization unit. Often the schemes of this type of radio amateurs are designed with their own hands on the LM317 chip. Such a device is easily assembled and has a small cost. But, in view of the very low efficiency and explicit limit on the power of the plug-in LEDs, the development prospects of linear converters are limited.

Pulse drivers may have an efficiency of more than 90% and a high degree of protection against network interference. Their power consumption is ten times less than the power given to the load. Due to this, they can be manufactured in a hermetic case and are not afraid of overheating.

The first impulse stabilizers had a complex device without idling. They were then upgraded and, due to the rapid development of LED technologies, specialized chips with frequency and pulsed modulation appeared.

Condenser divider power supply diagram

Unfortunately, in the design of cheap LED lamps on 220V from China, neither linear nor the pulse stabilizer is provided. Motivating an exceptionally low price of the finished product, the Chinese industry was able to simplify the power scheme as much as possible. It is not correct to call it the driver, since there is no stabilization. From the figure it is clear that the electrical lamp circuit is designed to work from the network 220V. The alternating voltage decreases by the RC chain and enters the diode bridge. Then the straightened voltage is partially smoothed by the capacitor and through the current-limiting resistor enters the LEDs. This scheme does not have a galvanic junction, that is, all the elements are constantly under high potential.

As a result, the frequent drawders of the mains voltage leads to the flickering of the LED lamp. Conversely, the overestimated network voltage causes an irreversible process of aging capacitor with loss of tank, and, sometimes, it becomes the cause of its rupture. It is worth noting that another, the serious negative side of this scheme is the accelerated process of degradation of LEDs due to an unstable power current.

Driver circuit on CPC9909

Modern pulse drivers for LED lamps have a simple scheme, so it can be easily made even with their own hands. Today, to build drivers, a number of integrated circuits are made specifically designed to control powerful LEDs. To simplify the task of electronic circuit lovers, the developers of integral drivers for LEDs in the documentation lead typical inclusion schemes and calculations of the strapping components.

Modern pulse drivers for LED lamps have a simple scheme, so it can be easily made even with their own hands. Today, to build drivers, a number of integrated circuits are made specifically designed to control powerful LEDs. To simplify the task of electronic circuit lovers, the developers of integral drivers for LEDs in the documentation lead typical inclusion schemes and calculations of the strapping components.

General

The American company IXYS has established the release of the CPC9909 chip, designed to control LED assemblies and high brightness LEDs. The driver based on CPC9909 has small dimensions and does not require large cash investments. The CPC9909 scheduling is made in a planar version with 8 outputs (SOIC-8) and has a built-in voltage stabilizer.

Due to the presence of a stabilizer, the operating range of the input voltage is 12-550V from the DC source. The minimum drop of voltage on LEDs is 10% of the supply voltage. Therefore, CPC9909 is ideal for connecting high-voltage LEDs. The ISS perfectly works in the temperature range from -55 to + 85 ° C, which means it is suitable for designing LED lamps and lamps for outdoor lighting.

Purpose of conclusions

It is worth noting that with the help of CPC9909, you can not only turn on and off the powerful LED, but also to control it with a glow. To learn about all the capabilities of the ISS, consider the appointment of its conclusions.

- Vin. Designed for supply voltage.

- CS. Designed to connect an external current sensor (resistor), with which the maximum LED current is set.

- GND. Total driver withdrawal.

- Gate. The output of the microcircuit. Submits to the valve of the power transistor the modulated signal.

- PWMD. Low frequency dimming input.

- VDD. Output to regulate the supply voltage. In most cases, it connects through the capacitor to the general wire.

- LD. Designed to set analog dimming.

- RT. Designed to connect the time of the specifying resistor.

Scheme and its principle of operation

Typical inclusion of CPC9909 with a 220V power supply is shown in the figure. The diagram is capable of controlling one or more powerful LEDs or LEDs such as High Brithtness. The scheme can be easily assembled with your own hands even at home. The finished driver does not need to adjust, taking into account the competent selection of external elements and comply with the rules of their installation.  The driver for the 220V LED lamp on the CPC9909 database works using the frequency-pulse modulation method. This means that the pause time is a constant value (Time-off \u003d const). The alternating voltage is rectified by a diode bridge and smoothed by the C1, C2 capacitive filter. Then it enters the chip VIN input and starts the process of forming current pulses at the Gate output. The output current of the microcircuit controls the Q1 power transistor. At the time of the open state of the transistor (the time of the "Time-ON") current current flows through the chain: "+ diode bridge" - LED - L - Q1 - R S - "-Deeper bridge".

The driver for the 220V LED lamp on the CPC9909 database works using the frequency-pulse modulation method. This means that the pause time is a constant value (Time-off \u003d const). The alternating voltage is rectified by a diode bridge and smoothed by the C1, C2 capacitive filter. Then it enters the chip VIN input and starts the process of forming current pulses at the Gate output. The output current of the microcircuit controls the Q1 power transistor. At the time of the open state of the transistor (the time of the "Time-ON") current current flows through the chain: "+ diode bridge" - LED - L - Q1 - R S - "-Deeper bridge".  During this time, the inductance coil accumulates energy to give it to the load during the pause. When the transistor closes, the throttle energy provides a load current in the chain: L - D1 - LED - L.

During this time, the inductance coil accumulates energy to give it to the load during the pause. When the transistor closes, the throttle energy provides a load current in the chain: L - D1 - LED - L.  The process is cyclic, as a result of which the current through the LED has a saw-shaped form. The greatest and smallest saw value depends on the inductance of the throttle and the operating frequency.

The process is cyclic, as a result of which the current through the LED has a saw-shaped form. The greatest and smallest saw value depends on the inductance of the throttle and the operating frequency.  The pulse frequency is determined by the resistance value of RT. The amplitude of the pulses depends on the resistance of the RS resistor. Stabilization of the LED current occurs by comparing the internal reference voltage IC with a voltage drop on R s. The fuse and thermistor protect the scheme from possible emergency modes.

The pulse frequency is determined by the resistance value of RT. The amplitude of the pulses depends on the resistance of the RS resistor. Stabilization of the LED current occurs by comparing the internal reference voltage IC with a voltage drop on R s. The fuse and thermistor protect the scheme from possible emergency modes.

Calculation of external elements

Frequency resistor

The duration of the pause is exhibited by an outer resistor R T and are determined by the simplified formula:

t pause \u003d R t / 66000 + 0.8 (ISS).

In turn, the time of the pause is associated with the fill and frequency coefficient:

t pauses \u003d (1-D) / F (C), where D is the filling coefficient, which is the ratio of the time of the pulse to the period.

Tok Sensor

The resistance value R S sets the amplitude current of the current through the LED and is calculated by the formula: R S \u003d U CS / (I LED + 0.5 * i l pulse), where U Cs is a calibrated reference voltage, equal to 0.25V;

I LED - current through the LED;

I l Pulse - the magnitude of the pulsations of the load current, which should not exceed 30%, that is, 0.3 * i LED.

After the transformation of the formula, take the form: R s \u003d 0.25 / 1.15 * i LED.

The power dissipated by the current sensor is determined by the formula: P S \u003d R S * I LED * D (W).

The installation is taken by a resistor with a reserve in power of 1.5-2 times.

Throttle

As is known, the throttle current cannot change the jump, increasingly during the pulse and descending time during the pause. The problem of the radio amateur is to choose a coil with inductance that provides a compromise between the quality of the output signal and its dimensions. To do this, remember the level of pulsations, which should not exceed 30%. Then it will take inductance with the face value:

L \u003d (US LED * T pauses) / I l Pulse, where u LED is a drop in the voltage on the LED (s), taken from the WAY schedule.

Power filter

Two capacitor are installed in the power circuit: C1 - for smoothing the straightened voltage and C2 - to compensate for frequency interference. Since CPC9909 works in a wide range of input voltage, then in the high capacity of electrolytic C1 there is no need. It will be enough 22 μF, but you can and more. Capacity of the Metal Farm C2 for the diagram of this type is standard - 0.1 μF. Both capacitors must withstand voltage at least 400V.

However, the microcircuit manufacturer insists on the installation of C1 and C2 capacitors with a small equivalent sequential resistance (ESR) to avoid the negative effect of high-frequency interference arising when drivers switching.

Rectifier

The diode bridge is selected based on the maximum direct current and reverse voltage. To operate in the network 220V, its reverse voltage must be at least 600V. The estimated validity of the direct current depends on the load current and is defined as: I AC \u003d (π * i LED) / 2√2, A.

The resulting value must be multiplied by two to increase the reliability of the circuit.

Selection of other scheme elements

Capacitor C3, installed in the chip power circuit, should be a capacity of 0.1 μF with a low ESR value, similar to C1 and C2. Unused PWMD and LD conclusions are also connected via C3 with a shared wire.

The transistor Q1 and diode D1 operate in a pulse mode. Therefore, the choice should be made with regard to their frequency properties. Only elements with low recovery time will be able to keep the negative effect of transients at the moment of switching at a frequency of about 100 kHz. The maximum current via Q1 and D1 is equal to the amplitude value of the LED current, taking into account the selected filling coefficient: I Q1 \u003d i D1 \u003d D * I LED, A.

The voltage applied to Q1 and D1 is pulsed, but not more than the straightened voltage, taking into account the capacitive filter, that is, 280V. The selection of Q1 and D1 power elements should be made with a reserve, multiplying the calculated data into two.

The fuse (FUSE) protects the emergency short circuit diagram and must hold the maximum current load for a long time, including pulse interference.

I fuse \u003d 5 * i ac, A.

The RTH thermistor installation is needed to limit the driver's starter when the filter capacitor is discharged. With its resistance, RTH should protect the pavement diodes from breakdown in the initial seconds of work.

R th \u003d (√2 * 220) / 5 * i ac, Ohm.

Other options for inclusion CPC9909

Smooth start and analog dimming

If desired, the CPC9909 can provide a soft switching on the LED when its brightness will gradually increase. Smooth start is implemented using two permanent resistors connected to the LD output, as shown in the figure. This solution allows you to extend the life of the LED.

Also, the LD output allows you to implement the feature of analog dimming. For this, the 2.2 com resistor is replaced with a variable resistor of 5.1 kΩ, thereby smoothly changing the potential at the LD output.

Pulse Diming

You can control the luminosity of the LED by feeding the rectangular pulses to the PWMD output (Pulse width modulation dimming). To do this, use a microcontroller or impulse generator with a mandatory separation through the optocoupler.

In addition to the driver version of the LED lamps, there are similar circuit solutions from other manufacturers: HV9910, HV9961, PT4115, NE555, RCD-24, etc. Each of them has its strengths and weaknesses, but in general, they are successfully coping with the assigned load When assembling with your own hands.

Read the same way

Homemade Driver for LEDs from the 220V network. Schemes ice drivers

Driver for LEDs do it yourself: Simple schemes with description

For the use of LEDs, a specialized driver is usually required as lighting sources. But it happens that there is no necessary driver at hand, but it is required to organize a backlight, for example, in a car, or test the LED on the brightness of the glow. In this case, you can make a driver for LEDs with your own hands.

How to make a driver for LEDs

The schemes below use the most common elements that can be purchased in any radio market. The assembly does not require special equipment - all the necessary tools are widely available. Despite this, with a neat approach of the device, they work quite a long time and are not very inferior to commercial samples.

Necessary materials and tools

In order to assemble a homemade driver, you will need:

- A soldering iron with a capacity of 25-40 W. It can be used and greater power, but it increases the risk of overheating elements and their failure. It is best to use a soldering iron with a ceramic heater and non-rooted sting, because The usual copper sting is quite quickly oxidized, and it has to be cleaned.

- Flux for soldering (rosin, glycerin, FKET, etc.). It is desirable to use a neutral flux - in contrast to active fluxes (orthophosphoric and hydrochloric acid, zinc chloride, etc.), it does not oxidize contacts and less toxic over time. Regardless of the flux used after assembly, it is better to wash it with alcohol. For active fluxes, this procedure is mandatory for neutral to a lesser extent.

- Solder. The most common is the slight-melting tin-lead solder Pos-61. Inhalation of vapors during soldering, but have a higher melting point with less fluidity and seam degradation with time.

- Small pliers for flexing conclusions.

- Locks or side cuts for biting the long ends of the conclusions and wires.

- Installation wires in isolation. The multi-core copper wires from 0.35 to 1 mm2 are best suitable.

- Multimeter to control the voltage at nodal points.

- Isol or shrink tube.

- A small styling plate of fiberglass. It will be enough for the board with dimensions of 60x40 mm.

Textolite Make Plata for Quick Installation

Simply drivers for LED 1 W

One of the simplest schemes for powering a powerful LED is shown in the figure below:

As can be seen, in addition to the LED, it includes only 4 elements: 2 transistors and 2 resistors.

The role of the current regulator passing through LED, there is a powerful field N-channel transistor VT2. The R2 resistor determines the maximum current passing through the LED, and also works as a current sensor for the VT1 transistor in the feedback circuit.

The larger current passes through VT2, the greater the voltage drops to R2, respectively, VT1 opens and lowers the voltage on the VT2 shutter, thereby reducing the current of the LED. This reaches the stabilization of the output current.

The power supply of the circuit is carried out from the source of the constant voltage 9 - 12 V, the current is at least 500 mA. The input voltage must be at least 1-2 per longer voltage drops on the LED.

The R2 resistor should dispel the power of 1-2 W, depending on the required current and the supply voltage. Transistor VT2 - N-channel, designed for current at least 500 mA: IRF530, IRFZ48, IRFZ44N. VT1 - any low-power bipolar NPN: 2N3904, 2N5088, 2N2222, BC547, etc. R1 - power 0.125 - 0.25 W resistance 100 com.

In view of the small number of elements, the assembly can be made by mounting:

Another simple driver diagram based on a linear controlled voltage stabilizer LM317:

Here the input voltage can be up to 35 V. Resistance to the resistor can be calculated by the formula:

where I is the current in amperes.

In this scheme, a significant power will be scattered on LM317 with a large difference between the supply voltage and the fall on the LED. Therefore, it will have to be placed on a small radiator. The resistor should also be calculated for the power of at least 2 W.

More clearly this scheme is considered in the following video:

Here it is shown how to connect a powerful LED using the batteries with a voltage of about 8 V. When the voltage drops on the LED about 6 per difference, it turns out a small, and the microcircuit is heated slightly, so you can do without a radiator.

Please note that with a large difference between the supply voltage and the drop on the LED, it is necessary to put a microcircuit on the heat sink.

Powerful driver with PWM input

The following is a diagram for powering powerful LEDs:

The driver is built on a dual comparator LM393. The scheme itself is a buck-converter, that is, a pulse reduced voltage converter.

Features Driver

- Supply voltage: 5 - 24 V, permanent;

- Output current: up to 1 A, adjustable;

- Output power: up to 18 W;

- Protection against KZ on exit;

- The ability to control the brightness with the external PWM signal (it will be interesting to read how to adjust the brightness of the LED ribbon through the dimmer).

Operating principle

The R1 resistor with a diode d1 form a reference voltage source of about 0.7 V, which is additionally regulated by the VR1 resistor. R10 and R11 resistors serve as current sensors for a comparator. Once the voltage on them exceeds the reference, the comparator closes, thus closing a pair of transistors Q1 and Q2, and those, in turn, will close the transistor Q3. However, the inductor L1 at that moment seeks to resume the current passage, so the current will flow until the voltage on R10 and R11 becomes less reference, and the comparator will not open the transistor Q3 again.

The pair Q1 and Q2 acts as a buffer between the exit of the comparator and the valve Q3. It protects the scheme from false positives due to the laying on the valve Q3, and stabilizes its work.

The second part of the comparator (IC1 2/2) is used to further adjust the brightness using PWM. To do this, the control signal is fed to the PWM input: when the logical levels of TTL (+5 and 0 c) are submitted, the diagram will open and close the Q3. The maximum signal frequency at the PWM input is about 2 kHz. Also, this input can be used to enable and disconnect the device using the remote control.

D3 is a Schottky diode, designed for current to 1 A. If it is not possible to find exactly the Schottky diode, you can use a pulse diode, for example FR107, but the output power will then slightly decrease.

The maximum current at the outlet is configured by the selection R2 and the inclusion or exception R11. So you can get the following values:

- 350 mA (LED with a power of 1 W): R2 \u003d 10K, R11 disabled,

- 700 mA (3 W): R2 \u003d 10K, R11 connected, 1 Ohm denomination,

- 1A (5W): R2 \u003d 2.7K, R11 connected, 1 Ohm denomination.

In the narrower limits, the adjustment is made by a variable resistor and PWM signal.

Build and configure driver

Installation of the driver components is made on the dumping board. First, the LM393 chip is installed, then the smallest components: condensers, resistors, diodes. Then transistors are put, and the last place variable resistor.

Place elements on the board is better so as to minimize the distance between the connected outputs and use as few wires as jumpers as possible.

When connected, it is important to observe the polarity of the connection of diodes and the pinout of the transistors, which can be found in the technical description of these components. Also, diodes can be checked using a multimeter in resistance measurement mode: in the forward direction, the device will show the value of about 500-600 ohms.

To power the circuit, you can use the external source of constant voltage 5-24 V or batteries. At the battery 6F22 ("Crown") and others too small capacity, so their use is impractical when using powerful LED.

After assembly, you need to adjust the output current. To do this, the LEDs are soldered to the output, and the VR1 engine is set to the extremely lower position (is checked by a multimeter in the "transverse" mode). Next, we supply the supply voltage to the input, and the rotation of the VR1 handle is achieved by the required brightness of the glow.

List of elements:

Conclusion

The first two of the considered schemes are very simple in the manufacture, but they do not provide protection against short circuit and have a rather low efficiency. For long-term use, a third scheme is recommended on LM393, since it is deprived of these shortcomings and has wider capabilities to adjust the output power.

ledno.ru.

220V LED Driver Scheme

The advantages of LED paws were considered repeatedly. The abundance of positive feedback of users of LED lighting will causes them to think about the own bulbs of Ilyich. Everything would be nice, but when it comes to the calculation of the re-equipment of the apartment on the LED lighting, the numbers are slightly "strained."

To replace an ordinary lamp on 75W, there is a LED light bulb for 15W, and such lamps need to be changed a dozen. With an average cost of about 10 dollars per lamp, the budget is decent, and it is also impossible to exclude the risk of acquiring the Chinese "clone" with a life cycle of 2-3 years. In the light of this, many consider the possibility of independent manufacture of these devices.

220V LED Power Theory

The most budget option can be collected with your own hands from these LEDs. A dozen such baby costs less than a dollar, and in brightness corresponds to the incandescent lamp by 75W. It is not a problem to collect all together, that's just you can not connect them directly - burned. The heart of any LED lamp is the power driver. It depends on how long the light bulb will shine.

To collect the LED lamp with their own 220 volts, we will understand in the power driver diagram.

Network parameters greatly exceed the needs of the LED. Whatever the LED can work from the network, it is necessary to reduce the amplitude of the voltage, current strength and convert the variable voltage of the network to constant.

For these purposes, a voltage divider with resistor or capacitive load and stabilizers are used.

Components of a diode lamp

The 220 volt LED lamp circuit will require a minimum amount of available components.

- LEDs 3.3V 1W - 12 pcs.;

- ceramic condenser 0.27MKF 400-500V - 1 pc.;

- 500Kom resistor - 1m 0.5 - 1W - 1 sh.

- 100V diode - 4 pcs.;

- electrolytic capacitors for 330MKF and 100MKF 16V 1 pcs.;

- voltage stabilizer to 12V L7812 or similar - 1pc.

Manufacture of LED drivers for 220V do-it-yourself

The layout of the ice driver for 220 volts is nothing but a pulse power supply.

As a homemade LED driver from a 220V network, we consider the simplest pulse power supply without galvanic junction. The main advantage of such schemes is simplicity and reliability. But be careful when assembling, since this scheme has no limit on the current current. The LEDs will select their last amps of the ampere, but if you are touched by the curtain wires with your hand, the current will reach a dozen amp, and such a current is very tangible.

The circuit of the simplest driver for 220V LEDs consists of three main cascades:

- Voltage divider on the capacitance resistance;

- diode bridge;

- tension stabilization cascade.

The first cascade is the capacitive resistance on the C1 condenser with the resistor. The resistor is necessary for self-discharge of the capacitor and does not affect the operation of the diagram itself. Its nominal is not particularly critical and can be from 100 to 1m with a capacity of 0.5-1 W. The capacitor is necessarily not electrolytic at 400-500V (efficient amplitude voltage of the network).

With the passage of the half-wave voltage through the capacitor, it skips the current until the hoist charge occurs. The smaller its capacity, the faster the full charge occurs. With a capacity of 0.3-0.4 mpq. Charging time is 1/10 of the network voltage half-wave period. In simple language, only a tenth of the incoming voltage will pass through the condenser.

The second cascade is a diode bridge. It converts alternating voltage to constant. After cutting off most of the half-wave voltage by the capacitor, at the outlet of the diode bridge we get about 20-24V DC.

The third cascade is a smoothing stabilizing filter.

The capacitor with a diode bridge perform a voltage divider function. When the voltage changes in the network, the amplitude will also change at the outlet of the diode bridge.

To smooth the voltage pulsation parallel to the circuit, connect the electrolytic capacitor. Its container depends on the power of our load.In the driver diagrater, the supply voltage for LEDs should not exceed 12V. As a stabilizer, you can use the distributed element L7812.

The collected scheme of the LED lamp by 220 volts starts to work immediately, but before turning onto the network, it is thoroughly insulating all the bare wires and places of the soldering of the schema elements.

Driver Option without current stabilizer

There is a huge number of drivers for LED drivers from a 220V network, which do not have current stabilizers.

The problem of any non-versionable driver is the pulsation of the output voltage, therefore, the brightness of the LEDs. The capacitor installed after the diode bridge partially copes with this problem, but it decides not completely.

On diodes there will be a pulsation with an amplitude of 2-3B. When we set the stabilizer to 12V into the scheme, even taking into account the pulsation of the amplitude of the incoming voltage will be higher than the clipping range.

Voltage diagram in scheme without stabilizer

Diagram in a scheme with a stabilizer

Therefore, the driver for diode lamps, even assembled with her own hands, in the level of ripples will not give up similar nodes of expensive lamps of factory production.

As you can see, collect the driver with your own hands does not represent much difficulty. By changing the parameters of the schema elements, we can vary the output values \u200b\u200bwidely.

If you have a desire based on such a scheme to assemble a 220 volt LED scheme, it is better to remake the output cascade of 24V voltage with the corresponding stabilizer, since the output current in L7812 1,2A, it limits the load capacity of 10W. For more powerful sources of lighting, it is required to either increase the number of output cascades, or use a more powerful stabilizer with output current to 5a and install it on the radiator.

svetodiodInfo.ru.

How to select LED Driver, LED Driver

The most optimal way to connect to 220V, 12B is the use of current stabilizer, LED driver. In the language of the alleged opponent, "LED Driver" is written. By adding the desired power to this request, you can easily find suitable items on Aliexpress or eBay.

- 1. Features Chinese

- 2. Service life

- 3. Ice Driver for 220V

- 4. RGB driver for 220V

- 5. Module for assembly

- 6. Driver for LED Luminaires

- 7. Power supply for LED tape

- 8. LED Driver do it yourself

- 9. Low-voltage

- 10. Brightness adjustment

Features Chinese

Many love to buy on the largest Chinese market for Aliexpress. Prices and range are pleased. LED Driver is most often choosing due to low cost and good characteristics.

But with an increase in the dollar, buying the Chinese has become unprofitable, the cost comes from the Russian, while there is no guarantee and the possibility of exchanging. For cheap electronics, the characteristics are always overestimated. For example, if the power of 50 watts is indicated, at best, this is the maximum short-term power, and not constant. Nominal will be 35W - 40W.

In addition, they are much saved on the stuffing to reduce the price. Some where there is not enough items that provide stable operation. The cheapest components are applied, with a short service life and low quality, so the percentage of marriage is relatively high. As a rule, components work at the limit of their parameters, without any stock.

If the manufacturer is not specified, he does not need to be responsible for the quality and feedback about his goods will not write. And the same item produces several factories in different configurations. For good items, a brand must be specified, which means it is not afraid to respond for the quality of its products.

One of the best is the MEANWELL brand, which values \u200b\u200bthe quality of its products and does not release junk.

Life time

Like any electronic device, the LED driver has a service life that depends on the operating conditions. Branded modern LEDs are already working up to 50-100 thousand hours, so food fails before.

Classification:

- consumer goods up to 20.000h.;

- secondary quality up to 50.000h.;

- up to 70.000h. Power supply on high-quality Japanese components.

This indicator is important when calculating payback to the long-term perspective. For domestic use, there is enough swirpotreb. Although the miser pays twice, and in LED searchlights and lamps it works great.

Ice driver for 220V

Modern LED drivers are structurally performed on the PWM controller, which can be very good to stabilize the current.

Main settings:

- rated power;

- working current;

- the number of connected LEDs;

- power factor;

- KPD stabilizer.

The housings for street use are performed from metal or shockproof plastic. In the manufacture of aluminum housing, it can act as a cooling system for electronic filling. This is especially true when filling the housing compound.

On labeling often indicate how many LEDs can be connected and what power. This value may not only be fixed, but also in the form of a range. For example, it is possible to connect the LEDs 12,220 from 4 to 7 pieces of 1W. It depends on the design of the electrical circuit of the LED driver.

RGB driver for 220V

The tricolor RGB LEDs differ from one-color in order to contain in one body crystals of different colors red, blue, green. To manage them, each color must be lit separately. Diode tapes are used by the RGB controller and power supply.

If the RGB of the LED is the power of 50w, then this is total for all 3 colors. To learn an approximate load on each channel, divide 50w to 3, we get about 17W.

In addition to powerful LED Driver there are 1W, 3W, 5W, 10W.

Remote control panels (DB) are 2 types. With infrared management, like a TV. With the control of radio channel, do not need to be directed to the signal receiver.

Module for assembly

If you are interested in ice driver for assembling with your own hands of the LED searchlight or lamp, you can use the LED Driver without a case.

If you already have a current stabilizer for LEDs, which is not suitable for current, it can be increased or decreased. Find the PWM controller chipboard from which the characteristics of the LED driver depend. It indicates the labeling that you need to find specifications for it. The documentation will indicate a typical inclusion scheme. Typically, the output current is set by one or more resistors connected to the legs of the chip. If you change the rating of resistors or put a variable resistance according to information from the specifications, you can change the current. Only it is impossible to exceed the initial power, otherwise it may fail.

Driver for LED Luminaires

Some other requirements are presented to power outdoor lighting. When designing outdoor lighting, the LED Driver will operate under -40 ° to + 40 ° in dry and wet air.

The pulsation coefficient for lamps may be higher than when using indoors. For street lighting, this indicator becomes not important.

When operating on the street, complete tightness of the power supply is required. There are several ways to protect moisture:

- pouring the whole fee with a sealant or compound;

- assembly block using silicone seals;

- placement of the LED driver board in one volume with LEDs.

The maximum level of protection is IP68, is indicated as "Waterproof Led Driver" or "Waterproof Electronic Led Driver". The Chinese have not a guarantee of waterproof.

In my practice, the claimed level of protection against moisture and dust does not always correspond to the real one. In some places may not be enough seals. Pay attention to the input and output of the cable from the body, samples are falling with a hole that is not closed with a sealant or in another way. Water on the cable can fly to the housing and then evaporate in it. This will result in corrosion on the board and open parts of the wires. This will repeatedly reduce the service life of the searchlight or lamp.

Power supply for LED ribbon

LED tape works on another principle, it takes a stabilized voltage for it. The current resistor is installed on the ribbon itself. This facilitates the connection process, you can connect the segment of any length starting from 3 cm to 100m.

Therefore, the diet for the LED tape can be made from any power supply unit by 12V from consumer electronics.

Main settings:

- the number of volts at the output;

- rated power;

- degree of protection against moisture and dust

- power factor.

LED Driver do it yourself

The simplest driver can be made in 30 minutes, even if you do not know the foundations of electronics. As a voltage source, you can use the power supply unit from the consumer electronics with a voltage from 12V to 37V. The power supply is especially suitable for a laptop, which has 18 - 19V and power from 50W to 90W.

It will be necessary to minimize the details, they are all depicted in the picture. The radiator for cooling a powerful LED can be borrowed from the computer. Surely somewhere at home in the storage room you are dusting old spare parts from the system unit. It is best to suit the processor.

CCTO would learn the quantity of the required resistance, use the calculator calculator calculator for LM317.

Before making LED Driver 50W with your own hands, it is worth a little search, for example, there is in every diode lamp. If you have a faulty light bulb, which has a malfunction in diodes, then you can use Driver from it.

Low-voltage

In detail we analyze the types of low-voltage ice drivers running from voltage up to 40 volts. Our Chinese brothers in mind offer many options. On the basis of PWM controllers, voltage stabilizers and current stabilizers are produced. The main difference, the module with the ability to stabilize current on the board is 2-3 blue regulators, in the form of variable resistors.

As the technical characteristics of the entire module, the parameters of the PWM chip on which it is assembled is indicated. For example, an outdated but popular LM2596 according to specifications is holding up to 3 amps. But without a radiator, it will endure only 1 amp.

A more modern option with improved efficiency is a PWM XL4015 controller designed for 5a. With a miniature cooling system, it can work up to 2,5A.

If you have very powerful supermarket LEDs, then you need a LED driver for LED lamps. Two radiator cooled the diode and the XL4015 chip. In such configuration, it is capable of working up to 5a with voltage up to 35V. It is desirable that he does not work in the limit modes, it is significantly improved its reliability and service life.

If you have a small lamp or a pocket spotlight, then you will fit the miniature voltage stabilizer, with a current to 1,5a. Input voltage from 5 to 23V, output to 17B.

Brightness adjustment

To regulate the brightness of the LED, you can use compact LED dimmers that have recently appeared. If its power is not enough, you can put a dimmer more. They usually work in two ranges on 12V and 24V.

You can manage using infrared or radioperate remote control (DB). They cost from 100 rubles for a simple model and from 200 rub model with remote control. Basically, such consoles are used for 12V diode tapes. But it can easily be put to a low-voltage driver.

Dimmation can be analog in the form of a spinning handle and digital in the form of buttons.

led-obzor.ru.

LED Driver

We will look at a truly simple and inexpensive powerful LED driver. The scheme is a source of direct current, which means that it saves the brightness of the LED constant, no matter what power you use. Ate when limiting the current of small supermarket LEDs, a sufficient resistor is sufficient, then a special scheme is needed for power over 1st watt. In general, it is better to feed the LED better than using a resistor. The proposed LED driver is ideal especially for powerful LEDs, and can be used for any number and configuration, with any type of power. As a test project, we took the LED element per 1 watt. You can easily change the driver elements to use with more powerful LEDs, on various types of power supply - BP, batteries, etc.

Technical characteristics of LED drivers:

Input voltage: 2B to 18V - output voltage: 0.5 less than the input voltage (0.5V drop on the field transistor) - Current: 20 amp

Details in the Scheme:

R2: approximately 100 ohm resistor

R3: The resistor is selected

Q2: Little NPN transistor (2N5088BU)

Q1: Large N-channel transistor (FQP50N06L)

LED: Luxeon 1-Watt LXHL-MWEC

Other driver elements:

A transformer adapter is used as a power source, you can use batteries. To power one LED 4 - 6 volts enough. That is why this scheme is convenient that you can use a wide range of power sources, and it will always shine equally. The radiator is not required, as about 200 mA current goes. If there is more current, you must set the LED element and the q1 transistor to the radiator.

The choice of resistance R3

The LED current is installed with R3, it is approximately equal: 0.5 / R3

The power dissipated on the resistor is approximately: 0.25 / R3

In this case, a current of 225 mA was installed using R3 by 2.2 ohms. R3 has a power of 0.1 W, thus, a standard 0.25 watt resistor fits perfectly. The Q1 transistor will work up to 18 V. If you want more, you need to change the model. Without radiators, FQP50N06L can only disperse about 0.5 W - this is sufficient for 200 mA current at a 3-voltage difference between the power supply and the LED.

Functions of transistors in the diagram:

Q1 is used as a variable resistor. - Q2 is used as a current sensor, and R3 is an installation resistor that leads to closing Q2 when the increased current flows. The transistor creates a feedback that continuously monitors the current current parameters and keeps it exactly in a given value.

This scheme is so simple that it makes no sense to collect it on the printed circuit board. Just connect the findings of parts by mounted mounting.

Forum for nutrition of various LEDs

elwo.ru.

Drivers for LED light bulbs.

A small laboratory on the topic "What driver is better?" Electronic or on capacitors in the role of ballast? I think that everyone has their own niche. I will try to consider all the pros and cons both of those and other schemes. Let me remind you the formula for calculating ballast drivers. Maybe anyone interested? We build your review on a simple principle. First, I will consider drivers on capacitors in the role of ballast. Then look at their electronic fellow. Well, at the end of the comparative conclusion. And now let's get to the point. Take a standard Chinese light bulb. Here is its scheme (a little improved). Why enhanced? This scheme will suit any cheap Chinese light bulb. The difference will be only in the ratings of radio components and the absence of some resistances (in order to save). There are light bulbs with missing C2 (very rarely, but it happens). In such light bulbs, the pulsation coefficient is 100%. Very rarely put R4. Although R4 resistance is simply necessary. It will be instead of a fuse, as well as soften the starting current. If there is no scheme, it is better to put. The current through the LEDs determines the rating of the C1 containers. Depending on what current we want to skip through LEDs (for self-delicacies), it is possible to calculate its capacity by formula (1).

There are light bulbs with missing C2 (very rarely, but it happens). In such light bulbs, the pulsation coefficient is 100%. Very rarely put R4. Although R4 resistance is simply necessary. It will be instead of a fuse, as well as soften the starting current. If there is no scheme, it is better to put. The current through the LEDs determines the rating of the C1 containers. Depending on what current we want to skip through LEDs (for self-delicacies), it is possible to calculate its capacity by formula (1).  I wrote this formula many times. I repeat. Formula (2) allows you to make the opposite. With it, you can calculate the current through the LEDs, and then the power of the bulb, without having a wattmeter. To calculate the power, we still need to know the voltage drop on the LEDs. You can measure the voltmeter, you can simply calculate (without a voltmeter). It is simply calculated. The LED behaves in the scheme as a stabilion with a stabilization voltage about 3B (there are exceptions, but very rare). With a sequential connection of the LEDs, the voltage drop on them is equal to the number of LEDs multiplied by 3B (if 5 LEDs, then 15V, if 10 - 30V, etc.). Everything is simple. It happens that the schemes are collected from LEDs into several parallels. Then it will be necessary to take into account the number of LEDs only in one parallel. Suppose we want to make a light bulb at ten LEDs 5730smd. According to passport information, the maximum current of 150mA. Let's calculate the light bulb for 100mA. There will be a reserve for power. By formula (1) we obtain: C \u003d 3.18 * 100 / (220-30) \u003d 1.67 MCF. Such capacity industry does not release, even Chinese. We take the nearest comfortable (we have 1,5mkf) and pass the current according to formula (2). (220-30) * 1.5 / 3,18 \u003d 90mA. 90mA * 30V \u003d 2.7W. This is the calculated power of the light bulb. Everything is simple. In life, of course, will be different, but not much. It all depends on the real voltage on the network (this is the first minus of the driver), from the exact container of the ballast, the actual voltage drop on the LEDs, etc. With the help of formula (2), you can calculate the power of the light bulbs already purchased (already mentioned). A drop of voltage on R2 and R4 can be neglected, it is slightly. You can connect a consistently many LEDs, but the total voltage drop should not exceed half the network voltage (110V). If this voltage is exceeded, the bulb is painfully reacting to all voltage changes. The more exceeds, the more painful reacts (this is a friendly advice). Moreover, these limits of the formula operates inaccurately. For sure no longer calculate. That appeared very big plus from these drivers. The power of the bulb can be customized under the desired result by the selection of the C1 container (both self-made and already purchased). But the second minus immediately appeared. The scheme does not have a galvanic junction with the network. If you poke into any place on the light bulb, the indicator will show the presence of the phase. Touch your hands (light bulb included in the network) is strictly prohibited. Such a driver has almost 100% efficiency. Losses only on diodes and two resistances. It can be made for half an hour (fast). Even the fee is not necessary. Condenters ordered these: aliexpress.com/snapshot/310648391.html aliexpress.com/snapshot/310648393.html diodes These are these: aliexpress.com/snapshot/6008595825.html

I wrote this formula many times. I repeat. Formula (2) allows you to make the opposite. With it, you can calculate the current through the LEDs, and then the power of the bulb, without having a wattmeter. To calculate the power, we still need to know the voltage drop on the LEDs. You can measure the voltmeter, you can simply calculate (without a voltmeter). It is simply calculated. The LED behaves in the scheme as a stabilion with a stabilization voltage about 3B (there are exceptions, but very rare). With a sequential connection of the LEDs, the voltage drop on them is equal to the number of LEDs multiplied by 3B (if 5 LEDs, then 15V, if 10 - 30V, etc.). Everything is simple. It happens that the schemes are collected from LEDs into several parallels. Then it will be necessary to take into account the number of LEDs only in one parallel. Suppose we want to make a light bulb at ten LEDs 5730smd. According to passport information, the maximum current of 150mA. Let's calculate the light bulb for 100mA. There will be a reserve for power. By formula (1) we obtain: C \u003d 3.18 * 100 / (220-30) \u003d 1.67 MCF. Such capacity industry does not release, even Chinese. We take the nearest comfortable (we have 1,5mkf) and pass the current according to formula (2). (220-30) * 1.5 / 3,18 \u003d 90mA. 90mA * 30V \u003d 2.7W. This is the calculated power of the light bulb. Everything is simple. In life, of course, will be different, but not much. It all depends on the real voltage on the network (this is the first minus of the driver), from the exact container of the ballast, the actual voltage drop on the LEDs, etc. With the help of formula (2), you can calculate the power of the light bulbs already purchased (already mentioned). A drop of voltage on R2 and R4 can be neglected, it is slightly. You can connect a consistently many LEDs, but the total voltage drop should not exceed half the network voltage (110V). If this voltage is exceeded, the bulb is painfully reacting to all voltage changes. The more exceeds, the more painful reacts (this is a friendly advice). Moreover, these limits of the formula operates inaccurately. For sure no longer calculate. That appeared very big plus from these drivers. The power of the bulb can be customized under the desired result by the selection of the C1 container (both self-made and already purchased). But the second minus immediately appeared. The scheme does not have a galvanic junction with the network. If you poke into any place on the light bulb, the indicator will show the presence of the phase. Touch your hands (light bulb included in the network) is strictly prohibited. Such a driver has almost 100% efficiency. Losses only on diodes and two resistances. It can be made for half an hour (fast). Even the fee is not necessary. Condenters ordered these: aliexpress.com/snapshot/310648391.html aliexpress.com/snapshot/310648393.html diodes These are these: aliexpress.com/snapshot/6008595825.html

But these schemes have another serious drawback. These are pulsations. Pulsation with a frequency of 100 Hz, the result of rectifying the mains voltage.

But these schemes have another serious drawback. These are pulsations. Pulsation with a frequency of 100 Hz, the result of rectifying the mains voltage.  Different light bulbs will differ slightly. It all depends on the value of the filter capacitance C2. The greater the capacity, the less rush, the less ripple. It is necessary to watch GOST R 54945-2012. And there it is written black on white that ripples with a frequency of up to 300 Hz are harmful to health. There is a formula for calculation (application d).

Different light bulbs will differ slightly. It all depends on the value of the filter capacitance C2. The greater the capacity, the less rush, the less ripple. It is necessary to watch GOST R 54945-2012. And there it is written black on white that ripples with a frequency of up to 300 Hz are harmful to health. There is a formula for calculation (application d).  But that's not all. It is necessary to watch sanitary standards SNiP 23-05-95 "Natural and artificial lighting". Depending on the purpose of the room, the maximum permissible pulsations from 10 to 20%. In life, nothing just happens. The result of the simplicity and cheapness of the bulbs is obvious. It's time to move to electronic drivers. Here, too, not everything is so cloudless. Here I ordered such a driver. This link is on him at the beginning of the review.

But that's not all. It is necessary to watch sanitary standards SNiP 23-05-95 "Natural and artificial lighting". Depending on the purpose of the room, the maximum permissible pulsations from 10 to 20%. In life, nothing just happens. The result of the simplicity and cheapness of the bulbs is obvious. It's time to move to electronic drivers. Here, too, not everything is so cloudless. Here I ordered such a driver. This link is on him at the beginning of the review.  Why ordered just such? Will explain. I wanted to "collect me" the lamps on 1-3 tons of LEDs. Pick up for the price and characteristics. I would suit me a driver for 3-4 LEDs with a current to 700mA. The driver must have a key transistor in its composition, which will automatize the driver control microcircuit. To reduce RF pulsations on the output should be a capacitor. The first minus. The cost of such drivers (US $ 13.75 / 10 pieces) differs in the most side of the ballast. But immediately plus. Current stabilization of such drivers 300mA, 600mA and higher. Ballast drivers this did not dream (no longer recommended). Let's look at the characteristics from the seller: AC85-265V "That Everyday Household Appliances." Load After 10-15V; CAN DRIVE 3-4 3W LED LAMP BEADS SERIES 600MA Here is the range of output voltages are small (also minus). Maximum, you can pick up successively five LEDs. In parallel, you can patch as much as you like. LED power is considered by the formula: The driver current is multiplied by the voltage drop on the LEDs [the number of LEDs (from three to five) and multiply the voltage drop on the LED (about 3B)]. Another big drawback of these drivers is large RF interference. Some instances hear not only FM radio, but also disappears with the reception of digital TV channels when they work. The frequency of the transformation is several tens of kHz. But protection is usually no (from interference).

Why ordered just such? Will explain. I wanted to "collect me" the lamps on 1-3 tons of LEDs. Pick up for the price and characteristics. I would suit me a driver for 3-4 LEDs with a current to 700mA. The driver must have a key transistor in its composition, which will automatize the driver control microcircuit. To reduce RF pulsations on the output should be a capacitor. The first minus. The cost of such drivers (US $ 13.75 / 10 pieces) differs in the most side of the ballast. But immediately plus. Current stabilization of such drivers 300mA, 600mA and higher. Ballast drivers this did not dream (no longer recommended). Let's look at the characteristics from the seller: AC85-265V "That Everyday Household Appliances." Load After 10-15V; CAN DRIVE 3-4 3W LED LAMP BEADS SERIES 600MA Here is the range of output voltages are small (also minus). Maximum, you can pick up successively five LEDs. In parallel, you can patch as much as you like. LED power is considered by the formula: The driver current is multiplied by the voltage drop on the LEDs [the number of LEDs (from three to five) and multiply the voltage drop on the LED (about 3B)]. Another big drawback of these drivers is large RF interference. Some instances hear not only FM radio, but also disappears with the reception of digital TV channels when they work. The frequency of the transformation is several tens of kHz. But protection is usually no (from interference).  Under the transformer something like "Screen". Must reduce interference. It is this driver almost no phonite. Why they are the foundation, it becomes clear if you look at the waveform oscillogram on the LEDs. Without capacitors Christmas tree much more serious!

Under the transformer something like "Screen". Must reduce interference. It is this driver almost no phonite. Why they are the foundation, it becomes clear if you look at the waveform oscillogram on the LEDs. Without capacitors Christmas tree much more serious!  At the output of the driver should be not only electrolyte, but also ceramics to suppress RF interference. Expressed my opinion. It is usually worth either something or other. It happens that nothing is worth it. It happens in cheap light bulbs. The driver is hidden inside, it will be difficult to present a complaint. Let's see the scheme. But I warn it, she is introductory. Only the main elements that are necessary for us for creativity (for understanding "what is what") is.

At the output of the driver should be not only electrolyte, but also ceramics to suppress RF interference. Expressed my opinion. It is usually worth either something or other. It happens that nothing is worth it. It happens in cheap light bulbs. The driver is hidden inside, it will be difficult to present a complaint. Let's see the scheme. But I warn it, she is introductory. Only the main elements that are necessary for us for creativity (for understanding "what is what") is.  Error in calculations is present. By the way, in the fine facilities, the devil also wipes. And now I consider pulsation (theory at the beginning of the review). Let's see what sees our eyes. I connect the photodiode to the oscilloscope. Two pictures combined into one for the convenience of perception. On the left, the light is turned off. On the right - the light is turned on. We look at GOST R 54945-2012. And there it is written black on white that ripples with a frequency of up to 300 Hz are harmful to health. And we have about 100 Hz. For eye harmful.

Error in calculations is present. By the way, in the fine facilities, the devil also wipes. And now I consider pulsation (theory at the beginning of the review). Let's see what sees our eyes. I connect the photodiode to the oscilloscope. Two pictures combined into one for the convenience of perception. On the left, the light is turned off. On the right - the light is turned on. We look at GOST R 54945-2012. And there it is written black on white that ripples with a frequency of up to 300 Hz are harmful to health. And we have about 100 Hz. For eye harmful.  I got 20%. It is necessary to watch sanitary standards SNiP 23-05-95 "Natural and artificial lighting". You can use, but not in the bedroom. And I have a corridor. You can SNiP and not to look. And now let's see another option for connecting LEDs. This is a diagram of connecting to an electronic drive.

I got 20%. It is necessary to watch sanitary standards SNiP 23-05-95 "Natural and artificial lighting". You can use, but not in the bedroom. And I have a corridor. You can SNiP and not to look. And now let's see another option for connecting LEDs. This is a diagram of connecting to an electronic drive.  Total 3 parallels of 4 LEDs. That's what the wattmeter shows. 7,1W active power.

Total 3 parallels of 4 LEDs. That's what the wattmeter shows. 7,1W active power.  Let's see how much comes to LEDs. Connected an ammeter and voltmeter to the driver output.

Let's see how much comes to LEDs. Connected an ammeter and voltmeter to the driver output.  Calculate purely LED power. P \u003d 0,49a * 12,1V \u003d 5.93W. All that is missing, took the driver. Now let's see what sees our eyes. On the left, the light is turned off. On the right - the light is turned on. The frequency of repetition of the pulses is about 100kHz. We look at GOST R 54945-2012. And there it is written black on white, that only ripples with a frequency of up to 300Hz are harmful to health. And we have about 100 kHz. For the eye harmlessly.

Calculate purely LED power. P \u003d 0,49a * 12,1V \u003d 5.93W. All that is missing, took the driver. Now let's see what sees our eyes. On the left, the light is turned off. On the right - the light is turned on. The frequency of repetition of the pulses is about 100kHz. We look at GOST R 54945-2012. And there it is written black on white, that only ripples with a frequency of up to 300Hz are harmful to health. And we have about 100 kHz. For the eye harmlessly.

He considered everything, everything measured. Now allotes the pros and cons of these schemes: the disadvantages of the light bulbs with the capacitor as ballast compared to electronic drivers. - The time of work is categorically impossible to concern the elements of the scheme, they are under the phase. - It is possible to achieve high currents of the luminescence of LEDs, because At the same time, large-sized capacitors are necessary. And the increase in the capacity leads to large starting currents, sprigs. -The large pulsations of the light flux rate of 100 Hz, require large filtering containers at the output. Pluses of light bulbs with a capacitor as ballast compared to electronic drivers. + The scheme is very simple, does not require special skills in the manufacture. + The range of output voltages is simply fantastic. The same driver will work with one and forty consistently connected LEDs. Electronic drivers output voltages have a much narrower range. + Low cost of such drivers, which is literally from the cost of two capacitors and a diode bridge. + You can make it yourself. Most details can be found in any shed or garage (old TVs, etc.). + You can adjust the current through the LEDs by the selection of ballast containers. + Indispensable as an initial LED experience as the first step in the development of LED lighting. There is one more quality that can be attributed to both the pros and cons. When using similar circuits with backlit switches, the light bulb lights are highlighted. For me personally, it is rather plus than minus. I use everywhere as duty (night) lighting. Do not deliberately write what drivers are better, everyone has their own niche. I posted a maximum of everything I know. Showed all the pros and cons of these schemes. And the choice how to always do you. I only tried to help. That's all! Good luck everyone.

mysku.ru.

How to choose the LED driver - views and main characteristics

LEDs were gained great popularity. The main role in this was played by the LED driver supporting the constant output current of a certain value. It can be said that this device is a current source for LED devices. Such a current driver, working with the LED, provides a long service life and reliable brightness. Analysis of the characteristics and types of these devices allows you to understand which functions they perform, and how to choose them correctly.

What is the driver and what is his appointment?

The driver for LEDs is an electronic device, at the output of which a constant current is formed after stabilization. In this case, no voltage is formed, namely the current. Devices that stabilize the voltage are called power supplies. The output voltage is specified on their enclosure. Power supplies 12 V are used to power LED lines, LED tapes and modules.

The main parameter of the LED driver, which he can provide a consumer for a long time at a certain load, is an output current. Separate LEDs or assemblies from similar elements are used as a load.

The LED driver is usually powered by a voltage 220 V. In most cases, the range of working output voltage is from three volts and can reach several dozen volts. To connect 3W LEDs in the amount of six pieces, you will need a driver with an output voltage from 9 to 21 V, designed for 780 mA. With its versatility, it has a small efficiency if it enable the minimum load on it.

When lighting in cars, in the headlights of bicycles, motorcycles, mopeds, etc., in the equipment of portable lanterns, a constant voltage is used, the value of which varies from 9 to 36 V. You can not apply the driver for LEDs with a small power, but in such Cases will need to make an appropriate resistor into a supply network of 220 V. Despite the fact that this element is used in the household switches, connect the LED to the network 220 V and rely on reliability is quite problematic.

Key Features

The power that these devices are capable of paying under load is an important indicator. Do not overload it, trying to achieve maximum results. As a result of such actions, drivers for LEDs or the LED elements themselves can fail.

The electronic filling of the device affects many reasons:

- protection class of the device;

- an element component that is used for assembly;

- input and output parameters;

- brand manufacturer.

The manufacture of modern drivers is performed using chips using a pulse transformation technology, which includes pulse converters and schemes, stabilizing current. PWM transducers are powered from 220 V, possess a high class of protection against short circuits, overloads, as well as high efficiency.

Specifications

Before purchasing a transducer for LEDs, the device characteristics should be studied. These include the following parameters:

- issued power;

- output voltage;

- rated current.

Connection diagram LED driver

The output voltage affects the connection scheme to the power source, the number of LEDs in it. The value of the current proportionally depends on the power of the diodes and the brightness of their radiation. The LED driver must issue so much current for LEDs as needed to provide constant brightness. It is worth remembering that the power of the desired device should be more consumed by all LEDs. It can be calculated using the following formula:

P (LED) - the power of one LED element;

n is the number of LED elements.

To ensure long and stable operation of the driver, the power supply reserve is 20-30% from the nominal.

By performing the calculation, the color factor of the consumer should be taken into account, as it affects the voltage drop. In different colors it will have different values.

Shelf life

LED drivers, like all the electronics, have a certain service life, which is strongly affected by operating conditions. LED elements made by famous brands are designed to work up to 100 thousand hours, which is much longer than power sources. By quality, the calculated driver can be classified into three types:

- low quality, with efficiency up to 20 thousand hours;

- with averaged parameters - up to 50 thousand hours;

- the converter consisting of components of well-known brands is up to 70 thousand hours.

Many do not even know why pay attention to this parameter. It will be needed to select a device for long-term use and further payback. For use in household premises, the first category (up to 20 thousand hours) is suitable.

How to pick a driver?