SMD components. SMD Components If SMD Condenser Changed Color

In our grief electronics, the main advantages of the electronic product are small dimensions, reliability, ease of installation and dismantling (equipment disassembly), low energy consumption as well as convenient useabriti ( from English - Ease of use). All these advantages are not possible without surface mounting technology - SMT technology ( S.urface. M.ont. T.echnology.), and of course, without SMD components.

What is SMD components

SMD components Used absolutely in all modern electronics. SMD ( S.urface. M.oUNED. D.evice.) that translated from the English is "the device mounted on the surface. In our case, the surface is a printed circuit board, without through holes for radio elements:

In this case, SMD components are not inserted into the opening of the boards. They are sealed by contact trackswhich are located right on the surface pCB. On the photo below the contact pads of the tin color on the mobile phone board on which there used to be SMD components.

Pluses SMD components

The largest plus SMD. Components are their small dimensions. In the photo below, simple resistors and:

Thanks to small dimensions of SMD components, developers have the opportunity to place large quantity components per unit area than simple output radio elements. Consequently, the installation density increases and the dimensions are reduced as a result. electronic devices. Since the weight of the SMD component is many times easier than the weight of the same simple output radio element, then the mass of radio equipment will also be more easily.

SMD components are much easier to fasten. For this we need with a hairdryer. How to Fall and Seet SMD components, you can read in the article how to solder SMD. Play them much harder. On the factories they have special robots on the printed circuit board. Manually in production, no one seals them, except radio amateurs and repairmen of radio equipment.

Multilayer fees

Since in the equipment with SMD components is very dense installation, then the tracks in the board must be greater. Not all walkways go on one surface, so the printed circuit boards do Multilayer. If the hardware is complex and has a lot of SMD components, then there will be more layers in the board. It is like a multi-layer cake from cortex. Print tracks connecting SMD components are directly inside the board and cannot be seen. An example of multilayer boards is fees mobile phones, computers or laptop boards (motherboard, video card, rAM etc).

The photo below the blue board is the iPhone 3G, the green board is the computer motherboard.

All repairmen of radio equipment know that if you have a multi-layer board, it sweeps a bubble. At the same time, interlayer connections are rushing and the fee comes into disrepair. Therefore, the main trump card when replacing the SMD components is correctly selected temperature.

On some boards, both sides of the circuit board are used, while the installation density, as you understand, is halved. This is another plus SMT technology. Oh yes, it is also worth considering that the factors that the material for the production of SMD components leaves several times less, and the cost of them during serial production in millions of pieces costs, in the literal sense, in a penny.

Main types SMD components

Let's look at the main SMD elements used in our modern devices. Resistors, capacitors, inductors coils with a small face value, and other components look like ordinary small rectangles, or rather, parallelepiped))

On boards without a scheme it is impossible to know, whether it is a resistor, whether the condenser is either the coil at all. The Chinese are waiting as they want. On large SMD elements, still put the code or numbers to determine their belonging and nominal. In the photo below in a red rectangle, these elements are marked. Without a scheme, it is impossible to say to which type of radio elements they relate, as well as their nominal.

SMD sizes components can be different. Here is a description of sizes for resistors and capacitors. For example, a rectangular SMD condenser yellow. They are also called tantalum or just tantals:

And here it looks like SMD:

There are also such types of SMD transistors:

Who possess a big denomination, in SMD execution look like this:

And of course, how without chip in our age microelectronics! There is a lot of SMD types of hoods of microcircuits, but I share them mostly into two groups:

1) Chips, whose conclusions are parallel to the printed circuit board and are on both sides or around the perimeter.

2) Chips, in which conclusions are under the chip. This is a special class of chips, called BGA (from English Ball Grid Array. - Array of balls). The conclusions of such chips are simple reinforcement balls of the same magnitude.

In the photo below the BGA chip and the inverse of its side, consisting of ball conclusions.

BGA chips are convenient to manufacturers by the fact that they greatly save space on the printed circuit board, because such balls under some BGA microcham can be thousands. This greatly facilitates the life of manufacturers, but does not make it easier for the life to repairers.

Summary

What still use in their designs? If your hands are trembling, and you want to do, a small radio product, then the choice is obvious. But still, in amateur structures, the dimensions do not play a big role, and the massive radio elements are much easier to solder and more convenient. Some radio amateurs use both. Every day all new and new chips and SMD components are being developed. Less, thinner, more reliable. The future is definitely for microelectronics.

In the element database of the computer (and not only) there is one bottleneck - electrolytic capacitors. They contain electrolyte, electrolyte is a liquid. Therefore, the heating of such a capacitor leads to its failure, since the electrolyte evaporates. And heating B. system block - Case regular.

Therefore, the replacement of capacitors is a matter of time. More than half failures motherboards Middle and Nizhny price category It occurs due to the fault of the dried or swelling capacitors. More often for this reason break computer blocks Nutrition.

Since printing on modern boards Very dense, it is necessary to replace capacitors very carefully. It can be damaged and at the same time not to notice a small inappropsy element or break (closure) tracks, thickness and distance between which a little more thickness of the human hair. Fix the like it is sufficiently difficult. So be careful.

So, to replace capacitors you will need a soldering iron with a subtle stall capacity of 25-30W, a piece of thick guitar string or a thick needle, a soldering flux or rosin.

In the event that you confuse polarity when replacing the electrolytic capacitor or install a low-faceted capacitor, it may well explode. But what it looks like:

So carefully select the item to replace and install the correctly. The electrolytic capacitors are always marked by minus contact (usually a vertical color strip other than the body color). On the printed circuit board, the hole for minus contact is also marked (usually with black hatch or solid white color). Ratings are written on the capacitor housing. There are several of them: voltage, tank, tolerances and temperature.

The first two is always there, the rest may be absent. Voltage: 16V (16 volts). Capacity: 220μF. (220 microfrades). These rates are very important when replacing. Voltage can choose equal or with a large face value. But the capacity affects the time of charging / discharge of the capacitor and in some cases may be important for the circuit section.

Therefore, the container should be selected equal to the one that is indicated on the housing. On the left in the photo below the green swollen (or dot) condenser. In general, constant problems with these green capacitors. The most frequent substitution candidates. On the right, a good capacitor, which will be soldered.

Condenser falls as follows: First, find the legs of the capacitor on the reverse side of the board (for me it is the most difficult moment). Then heated one of the legs and slightly pressing the capacitor body from the heated leg. When solder melts, the capacitor leans. Conduct a similar procedure with the second leg. Usually the capacitor is removed in two receptions.

It is not necessary to hurry to put pressure too much. Mat. Payment is not a double-sided textolitol, but a multi-layered (imagine a wafer). Due to excessive zeal, it is possible to damage the contacts of the inner layers of the printed circuit board. So without fanaticism. By the way, long-term heating can also damage the fee, for example, lead to the detachment or separation of the contact site. Therefore, it is also not necessary to put pressure on the soldering iron. Soldering galleries leaning, pressing the capacitor slightly.

After removing the damaged condenser, it is necessary to make holes so that the new capacitor is inserted freely or with a small force. For these purposes, I use a guitar string of the same thickness as the legs of the discharged part. For these purposes, a sewing needle is suitable, but the needles are now made from ordinary iron, and steel strings. There is a possibility that the needle will grab the solder and break when trying to pull it out. A string is flexible enough and the steel with the solder is much worse than iron.

When dismantling capacitors, solder most often clogs holes in the board. Having tried to hit the capacitor in the same way that I advised it to be filled, you can damage the contact pad and the track leading to it. Not the end of the world, but a very undesirable incident. Therefore, if the holes did not score solder, they just need to expand. And if it still scored, then you need to tightly press the end of the string or needle to the hole, and on the other hand, lean the soldering iron to this hole. If such an option is inconvenient, then the sore soldering should be leaning to the string almost at the base. When solder melts, the string will enter the hole. At this moment it is necessary to rotate it so that it does not grab the solder.

After receiving and expanding the hole, it is necessary to remove the excess solder from its edges, if any, otherwise a tin cap can be formed during the supply of a capacitor, which can solder adjacent tracks in those places where the print is dense. Pay attention to the photo below - how close to the holes are the paths. Such such is very easy, but it is difficult to notice, since the installed capacitor prevents the review. Therefore, the extra solder is very desirable to clean.

If you do not have a radio market, then most likely a condenser for replacement only can be used. Before mounting, it is necessary to process its legs if required. It is advisable to remove the entire solder from the legs. I usually smear the legs with a flux and a clean sketch of the soldering iron, I'm going to solder on the sting of the soldering iron. Then I bracle the feet of the capacitor with a stationery knife (just in case).

Here, in fact, all. We insert the condenser, lubricate the feet with flux and solder. By the way, if the pine rosin is used, it is better to pull it into powder and apply it to the place of installation than to make a soldering iron in a piece of rosin. Then it turns out neatly.

Replacing the capacitor without falling from the board

Repair conditions are different and change the capacitor on a multi-layer (mat. PC card, for example) a printed circuit board - this is not the same thing to change the capacitor in the power supply (single-layer one-sided printed circuit board). It is necessary to be extremely neat and careful. Unfortunately, not everyone was born with a soldering iron in their hands, but to repair (or try to repair) something is very necessary.

As I already wrote in the first half of the article, most often the cause of the breakdowns are condensers. Therefore, the replacement of capacitors is the most frequent type of repair, at least in my case. In specialized workshops there are special equipment for these purposes. If there is no, you have to use the equipment of the usual (flux, solder and soldering iron). In this case, experience is very helpful.

The main advantage this method It is that the contact pads of the board will have to be significantly less exposed to heat. At least twice. Printing on cheap mat. Payments quite often peeling from heating. The tracks are broken, and then it is rather problematic.

The minus of this method is that the fee will still have to prescribe, which can also lead to negative consequences. Although from my personal practice to crush a lot never had. At the same time there are all the chances of soldering to the legs remaining after the mechanical removal of the capacitor.

So, the condenser replacement begins with the removal of a spoiled part with a mat.

You need to put a finger on the condenser and with a light touch try to shift it up and down and left-right. If the capacitor swings to the left-right, then the legs are located along the vertical axis (as in the photo), in the opposite case by horizontal. You can also determine the position of the legs in a minus marker (strip on the capacitor body, denoting the minus contact).

Next should be pressed on the capacitor along the axis of its legs, but not sharp, but smoothly, slowly increasing the load. As a result, the leg is separated from the housing, then we repeat the procedure for the second legs (we give on the opposite side).

Sometimes the leg due to bad solder is pulled out with the condenser. In this case, you can slightly expand the resulting hole (I do it with a piece of guitar string) and insert a piece of copper wire there is preferably the same with a leg of thickness.

Half of the case is done, now go directly to replacing the condenser. It is worth noting that the solder does not stick to that part of the leg, which was inside the capacitor body and it is better to bite it off, leaving a small part. Then the legs of the capacitor prepared for the replacement and legs of the old capacitor are processed by the solder and solder. The most convenient to solder the capacitor, putting it to the board at an angle of 45 degrees. Then it can be easily put on the rack of sleep.

The view of course is non-psychic, but it works and this method Much easier and safer than the previous one from the point of view of heating with a soldering iron. Good repair!

If the materials of the site were useful for you, you can support the further development of the resource by providing it (and me).

We have already met the main radio components: resistors, condensers, diodes, transistors, chips, etc., and also studied how they are mounted on the printed circuit board. Recall the basic stages of this process again: the conclusions of all components are passed into the holes available in the printed circuit board. After that, the conclusions are trimmed, and then soldered on the reverse side of the board (see Fig. 1).

This process already known to us is called DIP installation. Such installation is very convenient for novice radio amateurs: large components, you can even solder them without a large "Soviet" soldering iron without a masculine or microscope. That is why all sets of whale master for self-soldering implies DIP installation.

Fig. 1. DIP installation

But Dip-Installation has very significant drawbacks:

Large radio components are not suitable for creating modern miniature electronic devices;

- output radio components are more expensive in production;

- A printed circuit board for DIP-installation is also more expensive due to the need to drill a plurality of holes;

- DIP-installation is difficult to automate: in most cases, even at large plants for the production of electronics, the installation and pack of DIP parts have to be performed manually. It is very expensive and long.

Therefore, the DIP installation in the production of modern electronics is practically not used, and the so-called SMD process, which is the standard of today, came to replace it. Therefore, any radio amateur should have at least a general idea.

SMD mounting

SMD components (chip components) are components electronic circuitPricing with the use of mounting technology to the surface - SMT technology (eng. surface. mount TECHNOLOGY) .T.e all electronic elementswhich are "enshrined" on the board in this way, are called SMD. components (eng. surface. mounted. Device). The installation process and soldering chip components correctly call the SMT process. Speaking "SMD-installation" is not entirely correct, but in Russia it was exactly this option of the name of the technical process, so we will speak the same way.

In fig. 2. The SMD installation board is shown. The same board performed on the DIP elements will have large dimensions several times.

Fig.2. SMD mounting

SMD Installation has undeniable advantages:

Radioetal cheaps in production and may be arbitrarily miniature;

- printed circuit boards are also cheaper due to the lack of multiple drilling;

- Installation is easy to automate: installation and soldering of components produce special robots. There is also no such technological operation as trimming conclusions.

SMD resistors

Acquaintance with chip-components is most logical to start with resistors, as from the simplest and most mass radio components.

The SMD resistor in its physical properties was similarly similar to us "ordinary", with an outdoor option. All its physical parameters (resistance, accuracy, power) are exactly the same, only the case is different. The same rule applies to all other SMD components.

Fig. 3. Chip resistors

SMD sizes SMD resistors

We already know that the output resistors have a certain grid of standard sizes, depending on their power: 0.125W, 0.25W, 0.5W, 1W, and the like.

The standard sizes grid is also available in chip resistors, only in this case the size is indicated by the four-digit code: 0402, 0603, 0805, 1206, etc.

The main sizes of resistors and their specifications shown in Fig.4.

Fig. 4 Basic sizes and parameters of chip resistors

SMD resistor marking

Resistors are marked with code on the case.

If there are three or four digits in the code, then the last digit means the number of zeros, in fig. 5. The resistor with the code "223" has such resistance: 22 (and three zero on the right) Om \u003d 22000 Ohm \u003d 22 com. The resistor with the code "8202" has resistance: 820 (and two zero on the right) Om \u003d 82000 Ohm \u003d 82 com.

In some cases, the marking is diguristic. For example, a resistor with code 4R7 has a resistance of 4.7 ohms, and a resistor with code 0R22 - 0.22 Ohms (here the letter R is a separator sign).

There are also resistors of zero resistance, or jumper resistors. Often they are used as fuses.

Of course, you can not remember the system of the code notation, but simply measure the resistance of the resistor to the multimeter.

Fig. 5 Marking chip resistors

Ceramic SMD capacitors

Externally, SMD capacitors are very similar to resistors (see Fig. 6). There is only one problem: the capacitance code is not applied to them, so the only way to determine is the measurement using a multimeter having a container measurement mode.

SMD capacitors are also available in standard sizes, as a rule, similar to the sizes of resistors (see above).

Fig. 6. Ceramic SMD capacitors

Electrolytic SMS capacitors

Fig.7. Electrolytic SMS capacitors

These capacitors are similar to their output fellows, and the marking on them is usually explicit: Capacity and work voltage. The strip on the "cap" of the capacitor is marked with its minus output.

SMD transistors

Fig.8. SMD transistor

Transistors are small, so it is impossible to write their full name on them. Restricted by code marking, and some international standard designations are not. For example, code 1e may designate the type of BC847A transistor, and maybe some other. But this circumstance is absolutely not bothering neither manufacturers or ordinary electronics consumers. Difficulties may occur only when repairing. Determine the type of transistor installed on the printed circuit board, without the manufacturer's documentation, it is sometimes very difficult for this fee.

SMD diodes and SMD LEDs

Photos of some diodes are shown in the figure below:

Fig.9. SMD diodes and SMD LEDs

On the diode body, polarity in the form of a strip is closer to one of the edges. Typically, the strip is marked with a cathode output.

SMD-CVDDD also has polarity, which is denoted by either a point near one of the conclusions, or somehow somehow (in detail it can be found in the component manufacturer documentation).

Determine the type of SMD diode or LED, as in the case of the transistor, it is difficult: a low-informative code is added on the diode housing, and there are no labels on the LED case at all, except for polarity label. Developers and manufacturers of modern electronics little care about its maintainability. It is understood that the printed circuit board will be a service engineer who has full documentation for a specific product. In such documentation, it is clearly described in which a printed circuit board is installed one or another component.

Installing and soldering SMD components

SMD installation is optimized primarily for automatic assembly Special industrial robots. But amateur radio amateur structures It can also be performed on chip-components: with sufficient accuracy and care to solder parts with rice grains, you can only know some subtleties to know.

But this is a topic for a separate large lesson, so it will be described in more detail about the automatic and manual SMD installation.

How to pay a domain name

How to pay a domain name Domain zone of tokelau islands

Domain zone of tokelau islands What is domain what problems may be

What is domain what problems may be Yandex Wordstat: detailed instructions for using the service and grouping operators and a complicated request

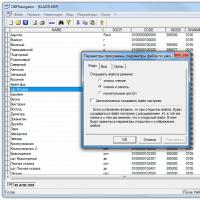

Yandex Wordstat: detailed instructions for using the service and grouping operators and a complicated request Editing DBF files

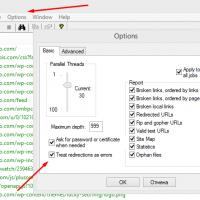

Editing DBF files Xenu Link Sleuth - What is this program how to use the Xenu program

Xenu Link Sleuth - What is this program how to use the Xenu program Methods Copy and insert text from keyboard without using mouse

Methods Copy and insert text from keyboard without using mouse