Restoration of drawers. Compare the length of diagonals without measuring their roulette

george_gl 12-07-2016 22:53

Your considerations?

KM 12-07-2016 22:55

on the side of the box appeared crack almost all height. I decided to glue for to buy a drawer in the province problematic. Conventional transparent plastic. The thought was such a cleaner with alcohol. The crack area is to apply cyanoacryl on the crack, and then glit a piece of plastic on the side inside inside.

But at work they said that could glue would be that to allocate that Neuav .... better epoxy ...

Your considerations?

At one time there was a problem with transparent capacity. No glue took. So if it is abs, then look for glue for the ABS, but he is expensive.

george_gl 12-07-2016 22:59

Box, whirpool, refrigerator 6 years

george_gl 12-07-2016 23:29

are you sad, but the option is similar to the tire only inside.

Apavel. 12-07-2016 23:55

Cyanocrelates like the stronghold of democracy came up during the Vietnamese war, as a means of rapid sealing wounds. Probably in the refrigerator D.B. less dangerous than when a hole in the car

ZY I can not be right. If so - inform

General Sisimus Stalin 13-07-2016 12:47

if you find a dichloroethane perfect thing for a polystyrene gluing (from it the box is made) Well, in the extreme case, adhesive from a collection of a collection of plastic and plastic tank

Nepushi 13-07-2016 05:41

1 - Dichloroethane does not need to look, it is sold there, where cyanacrylate and so on: usually these departments with any trifle with electrical goods, etc., where they sell the boor, fluxes, rosin, and so on. 2 - "glue for models" is a pear essence, a fully suitable and more harmless substitute for dichloroetan. 3 - cyanacrylate - the commercial name "second" is a good thing, but harmful, which can be seen from the name, and most importantly, orgohu does not dissolve, that is, it will simply explain it firmly, unlike dichloroethane; 4 - It is best to try Dichloroethane, but with him you need to be able to work correctly and it can be a modern plexiglass and not take, since it may also be some kind of modern, in addition to polystyrene now a lot of things.

Nepushi 13-07-2016 07:19

there is white and transparent

Soda + ka tax

Yep. 13-07-2016 07:46

qUOTE: Originally posted by george_gl:

better epoxy

epoxy is no better - its components are toxic themselves, and will be allocated even from frozen.

Nepushi 13-07-2016 07:50

Yes, and it glues only what is absorbed. The rest is simply reloading.

BARM. 13-07-2016 08:24

qUOTE: Initially, it is written inlet:

Soda + ka tax

not very in this case

fragant

dHE welds, and does not glue

Postoronnim V. 13-07-2016 08:29

qUOTE: Initially, the generalsimus Stalin is written:

... Dichloroethane is the perfect thing for sticking polystyrene ..

Least.

Nepushi 13-07-2016 08:39

qUOTE: Originally Posted by Barm:

dHE welds, and does not glue

Well, yes, because I am for him. Soda so remembered, a very garment method for other cases.

BARM. 13-07-2016 08:55

qUOTE: initially written Postoronnim V:Tetrahydrofuran will not be worse.

Least.

Postoronnim V. 13-07-2016 09:06

qUOTE: Originally Posted by Barm:

go to the store and buy it in a tube for example

Why do I need?

Won bottle of 0.9 liters on the shelf stands.

Price 309 rubles.

One of the best solvents and adhesives for polystyrene, PCV, etc.

BARM. 13-07-2016 09:33

how does it interact with products?

i'm afraid there is all the organizing agent, which recommended for gluing - will somehow interact

8Bullets. 13-07-2016 09:38

i'm afraid there is all the organizing agent, which recommended for gluing - will somehow interact

Therefore, I now do not buy a freezer with transparent, inexterial boxes.

I went to my new boxes in the internet - a difficult thing, although Papty Indesit.

Postoronnim V. 13-07-2016 09:55

qUOTE: Originally posted by 8Bullets:

but how does it interact with the products?

IMHO, here phobia is hardly relevant, because Few people think about how much the same poisonous furanovs are contained in the wrong honey, jam and some other products.

8Bullets. 13-07-2016 10:35

The solvent will exhale and how it will not interact with the products.

Well, this is the main thing.

http://hobbyostrov.ru/plastic-...ement-tm-87038/

Here, a small article with the brands of Adhesives found:

http://promresy.com/interesno/skleivanie-Plastika.html.

8Bullets. 13-07-2016 10:39

There, in the artist there is a video, how to glue a broken ear on the spotlight (relevant to me).

But, a little in off-top: how to glue the broken ear on the spotlight (missing (irrevocably) part of the plastic from the ear, the direct assholes of fragments are impossible to each other, you need to fill in the missing volume with something)?

BARM. 13-07-2016 10:57

qUOTE: Originally posted by 8Bullets:

need something to fill the missing volume)?

if AVS is the same Cosmofen, you can reinforce this grid of painting Iil as it is there, in the rolls such

8Bullets. 13-07-2016 11:01

qUOTE: initially written BARM:

if AVS is the same Cosmofen, you can reinforce this grid of painting Iil as it is there, in the rolls such

Thanks for clarifying! Some kind of fabulous Cosmofen, never seen this.

Postoronnim V. 13-07-2016 11:15

qUOTE: Originally posted by 8Bullets:

And what do you say about this glue, some kind of super-duper liquid adhesive EXTRA-THIN CEMENT?

Unfortunately I can't say anything, because Not known composition.

For the gluing polystyrene and the PCW, it is difficult to come up with something better than tetrahydrofuran. In it, these plastics are able to dissolve completely. TU. If there is a tetrahydrofuran - then it is possible to make glue by dissolving the same gluable material and in this glue will not be excess.

Close of cyclohexanon properties, but it dissolves slower.

The whole problem is that almost all of these substances are solvents of poisonous and in wide sale are limited.

Some are included in the list of precursors.

However, it is still possible to find them and acquire them.

For example, I acquired in the MSD-Kemick.

qUOTE: Originally posted by 8Bullets:

Broken ear on the spotlight (missing (irrevocably) part of the plastic from the ear, the direct assay of fragments is impossible to each other, you need to fill in the missing volume)?

As an option - cut "ear" from metal. Plates, heat and slightly fuse. The volume is filled with epoxy resin when it is in a soft state (starts to stick) or in a liquid making "formwork" from plasticine, for example.

8Bullets. 13-07-2016 11:29

8Bullets. 13-07-2016 11:31

qUOTE: Originally Posted by Postoronnim V:

As an option - cut "ear" from metal. Plates, heat and slightly fuse. The volume is filled with epoxy resin when it is in a soft state (starts to stick) or in a liquid making "formwork" from plasticine, for example.

Here, look, please - in this condition you can repair so much? In fact, this is all that remains, on the spotlight only a small fragment. And on this ear behind a few Ryube.

avkie. 13-07-2016 12:35

qUOTE: initially written george_gl:

on the side of the box appeared crack almost all height. I decided to glue for to buy a drawer in the province problematic. Conventional transparent plastic. The thought was such a cleaner with alcohol. The crack area is to apply cyanoacryl on the crack, and then glit a piece of plastic on the side inside inside.

But at work they said that could glue would be that to allocate that Neuav .... better epoxy ...

Your considerations?

the same was treated with epoxy + glass cholester

3 drawers in the freezer ariston.

avkie. 13-07-2016 12:37

fiberglass + epoxy.

stretch a lot of layers. Dry and out ... Process with a file

Longeron. 13-07-2016 12:51

While I thought how to glue the same crap and was not toxic, but I still think that all of the above is not for food storage, my wife glued a thermopystole for plastics.

avkie. 13-07-2016 12:56

well done wife. Where b such a south. And then my all saws - do, do it, then then it ...

no, it took and did it myself ..

Longeron. 13-07-2016 13:03

a thermopystole is a good idea.

and then we sometimes sometimes a problem with temporary fixation.

And if you still warm the pistol in front of the gun, then it is generally suitable for a permanent point.

She now offers him everywhere.

avkie. 13-07-2016 13:06

i'm usually an epoxy, fixing the Prykin - so that the details do not hold for a long time for a long time - it is not always possible to lock the cut

and Pokilipol now roads.

Longeron. 13-07-2016 13:21

qUOTE: Originally posted by 8Bullets:

I have been looking for your new boxes in the Internet - a difficult thing, albeit an intimate indie

It seems that all manufacturers will find FIG. Trend.

qUOTE: Originally Posted by Avkie:

i usually epoxy

Not. I somehow traveled to her, in my youth, 2101 jammed holes, so everything.

avkie. 13-07-2016 13:34

most likely it was polyester - styrene.

and the German Der-331 - it does not smell so at all - it smacks a hardener, but not compare with polyester - from her hair on the hands of green

Longeron. 13-07-2016 13:38

qUOTE: Originally Posted by Avkie:

epoxy (even Soviet EPD-20) - almost and does not smell.

It seems to her just glued. In a cardboard red and white box. In plastic dimensional bottles.

avkie. 13-07-2016 13:39

very strange, well, okay.

8Bullets. 13-07-2016 14:08

In general, nichrome of this Cosmofen we have no, but there is this:

BARM. 13-07-2016 14:16

the same Central Central Asian

well, we can with additives what

on the extreme and soda, we also advised

Taurus. 13-07-2016 14:19

Glued a similar container for the refrigerator Indesit ... cut off the shavings from the plot of a little care and dissolved it in Dichloroetan 1k1 ... During the day it turned out a thick glue ... here it was glued ... Cleets well even seams.

8Bullets. 13-07-2016 14:27

qUOTE: initially written BARM:

on the extreme and soda, we also advised

And "how much grams hang" (c)? I did not find a mention of the proportion in the subject.

BARM. 13-07-2016 15:41

qUOTE: Originally posted by 8Bullets:

And "how much grams hang" (c)?

here manual for example

http://www.yaplakal.com/forum2/topic1214660.html

Nepushi 13-07-2016 15:45

qUOTE: Originally Posted by Barm:

the same Central Central Asian

Perhaps no, there are usually written on Tsa-glue, "the second" will be called short.

8Bullets. 13-07-2016 15:52

qUOTE: initially written BARM:

here manual for example

http://www.yaplakal.com/forum2/topic1214660.html

Thank you, I understood.

Instructions for Lamers, like me:

1. Drops singing the bonded surfaces so as not to be trapped

2. Sprinkle with soda, wait, s, blow a lick

3. Sliced \u200b\u200bglue compound, dry

4. We sprinkle on top of soda, wait, s, blow up

- While the glue does not end (joke, clean on the eye of the tutorial sequence)

Something somehow shine is not aesthetic and not effective when gluing the ease of the end wall of the frost. Drawer to sidewalls, if and I will do that, then at a time.

8Bullets. 13-07-2016 17:11

recommended for freezer

Where to get?

avkie. 14-07-2016 06:58

qUOTE: Initially written D.Trump:

recommended for freezer

so is it not epoxy?

Longeron. 14-07-2016 08:17

qUOTE: so is it not epoxy?

And there is.

qUOTE: Originally Posted by Taurus:

Glued a similar container for the refrigerator indesit ... cut off the shavings from a plot of unimproved and dissolved it in dichloroethane 1k1 ... a thick glue turned out to be a thick glue ... so glued ..

Eh, do not save yourself ...

Still in a shipyard mug, we categorically prohibited to use their own dichloroethane.

SDR 14-07-2016 10:29

qUOTE: initially written george_gl:

on the side of the box appeared crack almost all height. I decided to glue for to buy a drawer in the province problematic. Conventional transparent plastic. The thought was such a cleaner with alcohol. The crack area is to apply cyanoacryl on the crack, and then glit a piece of plastic on the side inside inside.

But at work they said that could glue would be that to allocate that Neuav .... better epoxy ...

Your considerations?

epoxy - ugly but firmly

try glue for children's models

decatize alcohol

well, be prepared that the crack is already all

SDR 14-07-2016 10:29

In general, nichrome of this Cosmofen we have no, but there is this:Gentlemen, what do you say, it will be suitable for gluing the freezer trays?

below answered

no cyanocrilat

8Bullets. 14-07-2016 10:42

below answered

no cyanocrilat

SDR 14-07-2016 10:49

qUOTE: Initially, 8Bullets is written:In the sense that in this second there are cyanocrylate and in no case can be used for food trays? Or, on the contrary, there is no it in it?

8Bullets. 14-07-2016 10:57

qUOTE: Initially written SDR:these adhesives are not adapted for gluing power structures - do not hold

and the glue for models dissolves contact surfaces and forms a heavy-duty connection

SDR 14-07-2016 10:58

qUOTE: Initially, 8Bullets is written:I understood everything, thank you! You see such glue apparently in some big children's worlds (there is definitely not in small)?

in any where the models sell

even stronger will be the connection on epoxy, but .... it will be ugly

kRN / FROST. 17-07-2016 16:53

Glue for large-scale models was? 3 years - normal flight.

8Bullets. 26-07-2016 12:40

I repeat. At the weekend, I bought two glue in the children's world for these very models: for Sushot rubles Russian in a jar under a spruce brush and a German liquid in a tube. And pulled a box.

It turned out to be a surprise - even even the fragments of the bracket remained in the box at all and the side wall had to glue, pressed against the inner wall of the front panel.

From the first minutes, nothing happened - the glue is not captured immediately, like a super cement, and the walls are departed from each other. That German is that Russian. The Russians at the end so smeared that he is already drunk on the wall.

Spat, I decided to pull the screw with the nut, but I put the box on the edge and the book pressed. Two days later came, I was looking, and it seems like glued down.

I didn't try to dyprack each other - sorry.

Garbage is all, dear specialists, will not keep such a cold?

george_gl 28-07-2016 20:31

sklexed a dichloroethane box, first the box itself, then put the tires. 2 days flight, normal. If it can't get angry and reinforcing a thin metal mesh (hen the hairdryer) and the glue again.

Retractable boxes, for example, writing table, are usually overcrowded by the most diverse papers and objects, while they are quite often and sharply put forward and rushing. Naturally, they are rapidly wear out. The gaps appear, the guides are erased, the side walls break out, the rear stops fall out and so on. So, old drawers require qualified repair and restoration.

From the end of the XVIII century, the lateral sides of the drawers are traditionally attached "in the spike". The lower part slides in the grooves of the facial part. No matter how durable boxes, friction arising from manipulations with them inevitably leads to wear of contacting parts. Gradually, wooden surfaces are abruptly, the boxes begin to creak and, in the end, they can jam, which in turn leads to deformation of the furniture frame.

Mandatory preparatory work

Before proceeding with the work, you should carefully inspect the boxes to understand the design of the guide and sliding surfaces, and also make sure that they are disassembered and repairing. There are several ways to build depending on the purpose of furniture and placement of boxes.

With any restoration work, first of all it is necessary to refresh the tree, that is, to spend preventive work: eliminate cracked, fungus, traces of insect activities.

Furniture frame status

First of all, it is necessary to make sure the strength and sufficient rigidity of the furniture. With fully closed boxes, check the reliability of the attachment of the guides by which they slide. The absence or presence of skews of the frame is easily checked using a plumb and level. Even a small wear of the leg makes the entire frame unstable and disrupts its horizontality, which makes it difficult to put forward and switching boxes, accelerates wood wear. In such cases, dismantling of furniture and its re-gluing after eliminating the defects of individual parts are required. The lower part of the box is attached without gluing in grooves, several nails at the rear wall.

Over time, the lower part of the boxes is most widely wearing. Changes in the initial sizes perpendicular to the direction of wood fibers can reach 5%, as a result of the attached nails to the rear wall of the box, the bottom can form a small gap with its front part. Therefore, the joiners have a habit of leave a small margin in the rear of the bottom. In this case, it is enough to pull the nails, to promote the lower part of the box forward, to then insert into the grooves of the face and again to score nails. If the bottom consists of two bonded boards, you should make sure of the reliability of their gluing before installing the bottom in place. If the stock is not initially provided, a small wooden laying is used to eliminate the gap.

Spikes: Connections & Laques Schip are easily disassembled, but the spikes themselves break quite rarely. Gently disconnect them with the help of a wedge and a queen. For the connection, carbon or fishery adhesives are commonly used. The remains of the old glue are fairly easily removed by hot water and brush. After cleaning and drying parts, glue them again using the recommended glue varieties.

Side walls: The presence of grooves makes the lower part of the side walls of the box most susceptible to wear. It is here that you can often see cracks, and worse than chips. In order to preserve the previous wood, the breakaches can be glued with quite strong polyvinyl acetate adhesive (PVA). Its use is recommended only for fastening parts that are subsequent should not be understood. To preserve the color gamut of wood, PVA glue can be tinted with pimples. Strengthen the restored details with small bamboo spikes. It is not necessary to use nails: As a result of the wear of the tree, their caps can come out and damage the sliding guides.

If a slotted piece of wood is lost, carefully process the place of the chop with a small hacksaw and stick to it a new one, specially cut and corresponding to the size of the piece.

The lower edges of the side walls in the back of the drawer are most often wearing. They can be twisted or even break. In this case, they should be aligned and then glued the appropriate, cut out of wood, thin gasket. When processing the outer part of the side wall, it is impossible to use the classic planer, to remove the minimum layer of wood and the alignment of the surface is more suitable for the chisels or a special small planer, the front of which is removed, and the cutting blade slides ahead to the tool.

For the restoration of the side wall of the box, cut out a thin laying of suitable wood with a small margin for fitting. Then glue, and after drying the glue, spill the protruding parts.

With the help of the line, make a line on the side wall of the box in such a way as to maintain the old wood. For convenience, install the box on the workbench in the vertical position.

Guides: They are attached on the side walls of the furniture and consist of several details. The guide lumber is glued in the grooves of the racks or the furniture legs and serves as a drawer for the box. His parties always act.

The guide bar is attached on sliding surfaces and when moving gives a box parallel to it. The length of the bar must be approximately equal to two thirds of the length of the box. In its base, the box is made at an angle of 45 to facilitate the processing of the branches when it is installed on the sliding guide.

Finally, the compensating bar relies on the upper part of the side walls and prevents the drawer swing when it is completely open. In the back opposite the rack, there is a small wooden stop, which limits the movement of the drawer in the depth.

How to repair?

As a rule, guides made of soft wood breeds contribute to wear of furniture. After dismantling, you can turn them over and use again. Thus disappear the need for cutting and gluing the gasket, and the furniture is better saved.

If you cannot remove the guides, you need to handle the carrier surface and install the gasket. But the use of a planer in narrow places is difficult, and sometimes impossible. In this case, it can be recommended to clean the plot with a defect, apply a polymer resin on it (ED-5 or ED-6) and glue a thin wooden plate.

A small addition: adjusting the guide spend slightly above the transverse beam of the front part, if it is overlade. Thus, it will not be damaged when the drawer is opened. Missing or worn guides must be replaced, as they are absolutely necessary for normal operation of furniture. The surplus stops should also be fixed in place or replaced.

Do not forget about castles

Broken or lost screws, empty mounting holes talk about bad work of locks of boxes. Put locks in place using new mounting screws and conducting pre-cleaning and lubrication.

|

Usually the fibers of the tree in the lower, the reverse part of the box are directed to the same side as on its face. The bottom of the box is fastened with nails to the rear wall. |

|

Often nails rust, so they are not easy to pull them out. Relieve them with a hacksaw blade, then remove the bottom, install it in the passage slots and secure several nails. |

|

Connections & Laques Ship "are quite often open. Before proceeding to remove the remains of the old glue with hot water, remove the side walls of the drawer. To remove a large number of old glue, you can use a knife or chisel. |

|

For fastening compounds & Laques of spikes, it is preferable to use animal adhesives (carpentry or fish). So that the gluing was more efficient, warm the surface with a hairdryer for paint removal or over an electric stove, while observing the rules of fire safety and extreme caution. |

|

Turn the glued parts with clamps, paying special attention to the proper installation of the corners. For this purpose, you can use two rails: Compare the length of the diagonals, which should be absolutely the same. |

|

Box in the section: 1. Compensation bar. 2. Gliding guide. 3. Side guide. 4. Side wall of the drawer. 5. Lower part (bottom) of the drawer. |

|

Drill the electric drill at a low hole speed for bamboo spikes. Such spikes with a small diameter have sufficient strength, so quite deeply enter the drawer wall, not splitting it. |

|

For more efficient gluing, expode damaged parts. If necessary, completely replace the contacting parts and secure them with bamboo spikes. |

|

A small height of the side walls of the drawer can slightly comprehend their clamp. To compensate for the difference in the levels, put a small focus on the back side of the side wall, and then other stops from above and below. |

|

Turn over the box and use the ruler in parallelism of the upper and lower planes of its side walls. With a strict horizontal facial side, as a result of wear, a noticeable bevel may appear on them, descending towards the rear wall of the box. |

|

Fully eliminate the SCO using the plane, thereby restoring the horizontal of the planes. |

|

Cut the jigsaw saw appropriate laying along the tree fibers. Before sawing, the bonded surfaces should be thoroughly held by the plane, since with a small thickness of the laying it will be impossible to clamp in the vice. |

|

Carefully apply PVA glue on both bonded surfaces. Glue, usually white, in this case tinted with pimples. After drying the glue and processing, the bonding line will become almost invisible. |

|

For proper Installation The gasket is made with a slight margin in height, width and length. |

|

To process the glued gasket, use a special planer. Remove the protruding parts, trying not to damage the wood furniture. |

|

With the help of the line, make a line on the side wall of the box in such a way as to maintain the old wood. For convenience, install the box on the workbench in the vertical position. |

|

Over time, the guide slip, made of soft wood, expand and increase in height. Thus, they are increasingly wearing, sowers are formed, preventing the drawer spreading. |

|

If it is impossible to dismantle the guides, treat them on the plane on the place to eliminate the sizes. It is processed only by the sliding guide, and the side guide the bar serves as a support. |

|

Adjust the gasket cut out of durable wood, for example, from beech, on the surface of the side guide. In this case, there is no need to provide for admission to the subsequent processing of the gasket, adjust its position in place before gluing, as this operation will subsequently be difficult. |

|

Due to limited access to the processing section, the exhausting of the gaps and bars without dismantling furniture requires certain skills, as well as the use of special tools, such as a branch with two replaceable blades. |

|

The last phase of the restoration of the guides is an adjustment or replacement of the stops. In this case, the focus from the tree is attached with nails to the rear desk of the desk without removing the box from it. |

I think many have come across the problem of cracked transparent plastic shelves and boxes in the refrigerator. The aesthetic component suffers, but most importantly, the functionality suffers.

Buying a new one is not an option, they may not be available at all or already. You can try to glue.

Shelves are often made from polystyrene, this can be judged by the PS icon on the shelf. There is a question than glue.

Several times I tried to glue parts made of polystyrene superclaim (cyanacrylate). Glues badly long. How reliably the connection I did not check, but the experience of circulation of things glued cyanacrylate, indicates the low reliability of such repairs.

The search issued some glue for models, which is designed to glue the polystyrene. He did not have to look for a long time, bought in the store of children's goods, 70 rubles for 12 ml. Naturally, there are other options like Dichloroetan, but I decided to dwell on it.

So, proceed.

I do not know how glue is applied when assembling models, I considered relevant use of a disposable syringe for these purposes.

The syringe was not melted from the glue, lucky.

For a sample, about 0.2 ml of glue scored in a syringe. Slightly pressing the piston spent on one of the glued surfaces. The glue goes easily, the uniformity of application I was first failed to control well.

The smell is very strong, even do not think to glue in an unbelievable room.

After applying glue, pressed the parts to each other. Excess glue in large quantities. I tried to erase with a paper napkin. Wood, but there were traces of glue. Plastic in glue is quite a lot, because traces are noticeable.

Glue grabbed very quickly. I did not squeeze the glued parts, I just left to dry. The smell of glue from the detail was felt and a few hours after gluing. I suppose it is better to wait at least 12 hours at room temperature for satisfactory evaporation of toluene and ether.

After receiving some experience, continued to repair. In the queue box.

It turned out that with some skill glue with the needle can be applied quite evenly with a thin layer, leading the needle on the surface of the plastic. With this applying, the excess glue is almost not highlighted from the seam.

This time the glue also grabbed quickly, I did not hold pressed the piece.

It turned out not very smoothly, but it makes no sense to get the perfect result.

Those who glued superclaim know that he has a very small surface tension, it spreads well on the surface, will not be left and the smallest hole, where it does not go.

That glue for models that I used, does not have this property to fly into all cracks. So there was an outstanding cracked by me anointed, but I don't think it helped prevent their growing up.

After 12 hours, the shelf and the box were washed with hot water with soap and took their place

Trying to understand why the boxes break, I came to the conclusion that it was not only the negligent attitude of the user to the brittle plastic parts. Problem and design. For example, in my refrigerator at the bottom of the main compartment, two boxes for vegetables. When they are riding them, they are fighting with force on the front edge of the glass shelf, while the drawer seeks to continue the movement. As a result, at the place of the application of the load, he broke. There are two solutions here - either to raise the shelf, or attach something soft to the rear wall of the box or the branch itself. Porolon is not suitable here, but a piece of thermal insulation "foam", I think, will be just right. Same and the rest problem places. Before gluing, eliminate the causes of cracking, otherwise the repair will turn into Martushkin work.

This article will describe in detail the manufacture of a box for instrumentation, spare parts, batteries and tools - the so-called flight box. But this box is made, taking into account the fact that there is a car for trips to the field, and therefore it is quite large and heavy.

Materials:

- Plywood (4mm)

- Strapiki

- Wooden bars 25x15 mm

- PVA glue

- varnish

- Selfness

- Carnations

Purchased details:

- doorhandle

- loops

- Castles-hooks

- legs

Instruments:

- Handsman on a tree

- Lobzik

- ruler

- Galnik

- Pencil

- sandpaper

- a hammer

- Iron

- Brush

Since there is a little experience in the furniture design programs, I also made a box in such a program - Pro100.. A file with the extension * .sto is a drawer project with all sizes. But in general, this box, depending on your equipment and tools, can be completely different sizes and another number of internal boxes.

Step 1. Drinking Drawer Details

To begin with, we buy a sheet of plywood with a thickness of 4 mm. You can thicker, but the box will then be more difficult, which is not very desirable.

The process of transportation (and the acquisition itself, of course, everyone will have their own, but the box is needed about such a sheet of plywood - 1.5x1.5 meters).

Then we cut the sheet to the desired parts and turn the edge of the sandpaper slightly.

From the bar (15x25 mm) we cut four long and four short lumps, and from the window head sprinkle the same pieces for the length of the slices - for the corners of the box.

We drink the inner partitions and make in parts of the crossbar, feeding the jigsaw on the poles.

Step 2. Leveling parts

This step is optional, since if you are lucky to purchase a flat paneur, it will not have to align. Otherwise, there will be a couple of extra days on this process. In general, on the Internet, it is fully information about how to direct Faneru, but will briefly tell.

So, for the start, drinking pieces we run by hot water (I scored in the bathroom water and threw all the details there).

Then a heated iron (preferably with steam), smoothed uneven details. You can right on the tile floor.

Now the heated parts are placed on a flat surface, you can in several layers.

From above covering smooth planes from chipboard or drawers with tools and press the cargo. I used basins and bottles with water.

Because in the bathroom, I have a heated floor, the details were smooth and almost dry. But maybe it will take another day for the final drying of plywood.

Step 3. Bonding Box

In the future, all items will be additionally bonded by self-draws and cloves, but first it is necessary to glue the PVA glue.

On the sidewalls of the box, blacksmith lines for which the strokes will be glued. Then glue the strokes (indent from the edge of 4 mm, on the thickness of plywood).

On the sidewalls, the lid is similar to the diameters of the line and glue the strokes.

We leave them for half an hour to dry the glue.

Then, according to a predetermined lines, we glue to the sidewalls of the rails with a cross section of 15x25 mm.

Similarly, we do with the sidewalls of the lid.

Then put parts under the press and leave until complete drying of the glue.

When the glue is dry, you can glue the inner partitions to the sidewalls of the box and plywood strips on the bars.

With the help of the kitchen and girlfriend, we glue the end wall with the side wall.

Then we glue the second side and end walls, fix cloves and leave until complete drying.

We glue the bottom and additionally fix cloves at the corners (in the strokes) and self-drawing (in the rails).

We glue the inside walls to the sidewalls.

The lid glue at once on the basis.

And we glue the narrow plywood strips, thus forming a slot for the inner cover. The inner cover itself from one layer of plywood and a stapper, for which it will be advanced.

Step 4. Grinding and varnishing

We apply the cover to the box, press and grind all the surfaces of the sandpaper to align the joints.

Cover the drawer acrylic varnish in two layers.

The inner lid is in one layer.

Step 5. Screening loops, locks, handles and legs

Under the loops we make small grooves and screw them with self-draws to the lid.

Then we screw the cover to the box, close and mark the locations for locks. Castles also fasten with self-draws.

To the cover from the inside we glue the plywood strip to harden the place under the handle.

Place and drill holes for bolts.

Screw the handle.

By the bottom of the drawer, we screw the plastic legs with self-draws.

Step 6. Production of internal boxes and partitions

Inside the box glit plywood partitions.

This is how the equipment and the boxes with bolts and other small things will be located.

With the skewers of the products will be finished due to the right techniques of work and devices.

You have only a few minutes to collect the details of the project, align the edges and tighten the clamps. By the way, are you sure that all the corners are direct? Using the right tools and devices, as well as several useful SovietsYou will be able to seek the ideal results every time without too much fuss.

The accuracy of the assembly depends on the rectangles of the parts, so before starting the processing of parts, make sure your equipment (saw, planing, flights and other machines) are configured correctly. Then prepare for the assembly smooth and clean work surface. For successful work, lighten one or more tested techniques to help avoid distortions.

One detail levels another

Dry the drawer and shake it from side to the side to make sure that the bottom inserted the bottom provides the rectangle of the assembly.

If all the details of your project initially had straight corners, when assembling, they would mutually align each other, provided that the clamps are installed correctly. As shown by top photopleashed exactly at the right corner, the crossbars are automatically leveling the frame. The trick is to direct the plot of clamp perpendicular to the edges of the parts. If you arrange a clamp at an angle, the pressure can lead to distortion.

Another way to make an assembly of self-leveling - plywood bottom or rear wall should be tightly inserted into the sheets or folds to save the rectangle of the drawer or case (Photo a).

Wanted gaps around the bottom or panel to compensate for sizes during seasonal moisture fluctuations?

To build a drawer, having a bottom, insert the assembly pattern into it and secure the clamps. Pressure clamps distribute clamping bars installed next to the connections, and not on top of them.

Make a simple assembly pattern, tightly inserted in the dump (photo B),and make cutout at its corners so that it does not stick to the details.

Collecting boxes in which straight spikes slightly perform at the corners, use spacers or clamping bars, as shown on (photo B),to the lips of the clamps do not touch the compounds. This method will come in handy and when assembling connections like "Lastochkin Tail".

Like the template

For accurate alignment and fixation of simple jack connections, it is convenient to use the metal mounting kit (photo s),which holds the details at a right angle to each other and prevents them off. If you prefer homemade fixtures, make your own assembly solutions of any size (PhotoD.). Short advice! No mounting squares? There is a way to ensure the fixedness of the details of the jack jack when gluing. First apply glue to the end of one detail, then connect both parts, having silent them to distribute the glue. Disconnect them for 10-15 seconds, allow the adhesion to dry a bit and become more viscous and sticky, and then again put the parts one to another. Increasing the viscosity of glue will help avoid the shear of parts when installing clamps.

This mounting kit due to rounded exterior corner fits tightly to both glued parts.

Determining the dimensions of the homemade mounting of the carbon, make cutouts in it corresponding to the sponges of the clamps you have.

Other self-made fixtures for alignment - clamping bars or planks of arbitrary sizes with cutouts, holding parts in the desired position and simultaneously distributing the pressure of clamps (Photo E).Brushes-prism with V-shaped grooves will help tightly pull the parts of the angular compounds on the Us.

Cutouts in the clamping bars prevent the shift of the parts, and the prism bruks, tightened by the clamps on the diagonals, compress the details together.

The steel tape of this clip distributes pressure on all four angle, tightly tightening the joints of the buried parts.

Some clamping devices due to the design features help ensure the rectangle of gluing. For example, a tape clip with four angular blocks (PhotoF.) and quadrilateral screw clip for assembling frames (PhotoG.) all four angle simultaneously align simultaneously.

Fourth-sided screw clamps, usually used when gluing a frame, you can use pairs to build boxes. Metal corner parts help to achieve rectangles.

Compare the length of diagonals without measuring their roulette

Not even having a calibration of the square, which can be trusted, you can check the rectangle of the assembly, comparing the distances between opposite angles. If the diagonals are equal (and the opposite parts also have the same length), you can be sure that all the corners are straight. If the measurements with a roulette are interfered with clamps or if you glue several identical products, try applying another method. Drink two thin rails from trimming. The length of each of them should be more than half the length of diagonals. Then do hard one of the ends of each rail at an angle of about 30 °. By pressing the squeaks to the opposite internal corners of the assembly, fold the rails together and secure them with a clamp. Then the same test rail measure another diagonal to make sure the assembly rectangle. To eliminate skews with a long clamp, carefully tighten the opposite angles along a longer diagonal.

Not even having a calibration of the square, which can be trusted, you can check the rectangle of the assembly, comparing the distances between opposite angles. If the diagonals are equal (and the opposite parts also have the same length), you can be sure that all the corners are straight. If the measurements with a roulette are interfered with clamps or if you glue several identical products, try applying another method. Drink two thin rails from trimming. The length of each of them should be more than half the length of diagonals. Then do hard one of the ends of each rail at an angle of about 30 °. By pressing the squeaks to the opposite internal corners of the assembly, fold the rails together and secure them with a clamp. Then the same test rail measure another diagonal to make sure the assembly rectangle. To eliminate skews with a long clamp, carefully tighten the opposite angles along a longer diagonal.

Magnetometry in the simplest version The ferrozond consists of a ferromagnetic core and two coils on it

Magnetometry in the simplest version The ferrozond consists of a ferromagnetic core and two coils on it Effective job search course search

Effective job search course search The main characteristics and parameters of the photodiode

The main characteristics and parameters of the photodiode How to edit PDF (five applications to change PDF files) How to delete individual pages from PDF

How to edit PDF (five applications to change PDF files) How to delete individual pages from PDF Why the fired program window is long unfolded?

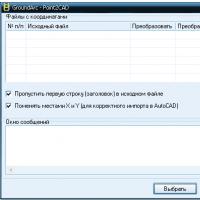

Why the fired program window is long unfolded? DXF2TXT - export and translation of the text from AutoCAD to display a dwg traffic point in TXT

DXF2TXT - export and translation of the text from AutoCAD to display a dwg traffic point in TXT What to do if the mouse cursor disappears

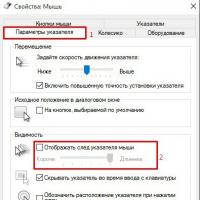

What to do if the mouse cursor disappears