Depth metal detector diagram with their own hands. How to make a simple metal detector with your own hands - step-by-step instructions. Metal detector do it yourself from DVD -Disc

Metal detectors are used to detect invisible items that, according to their electromagnetic properties, differ from the environment in which they are. Metal detectors use: amateur-archaeologists, geologists, treasure detectors. Also these devices use sappers to detect shells, builders to search for metal parts of structures (fittings, pipes ...).

Most metal detectors are very similar, but in fact they differ very much in their properties, and depending on the purpose of use. Here are some photos often used metal detectors. As well as a simple metal detector scheme.

How are metal detectors arranged?

The device of the metal detector is pretty simple. And it can be collected with your own hands at home. For this you do not need to have deep knowledge of electrical engineering. We have prepared a step-by-step instruction for you, which will help you to assemble the amateur metal detector from the remedies.

But first, let's learn what types of metal detectors exist which properties have different models and how to choose the model for you. In order to choose a suitable type of metal detector, you need to be determined: what specifications you need.

Here are some characteristics for which the quality of the device is judged:

The penetrating ability of the detector. What depth the electromagnetic field of the detector coil penetrates. It depends on how deep the device will "see" the metal in the ground or other environment.

Purchased search area. Usually, metal detectors explore the soil stripes. This parameter determines the width of such strips.

The susceptibility of the device. From this depends whether your metal detector detects minor metal objects (for example, coins).

Fragment of detector. This feature is responsible for the ability of the detector to respond only to the desired items (for example, non-ferrous metals).

Stability of the seeker to interference. In addition to its own electromagnetic field, the device can fall into electromagnetic fields of other devices. (mobile devices, power lines, radio stations ...). The best is the metal detectors that do not respond to fields of other sources.

Energy intensity. How many hours of searching should have a single battery or battery charge.

Frequency classification

In addition, metal detectors are classified at operating frequency. Exist:

Metal detectors operating at ultra-low frequencies. Such devices use only professionals. They are characterized by good technical parameters, but for their functioning requires dozens of watts of energy. Usually installed on special cars with capacious batteries and equipment, which allows you to determine the size, shape and structure of detected items.

Metal detectors operating in the low frequency range (from 300 Hz to several thousand Hz). Easily manufactured. Resistant to interference, but have low susceptibility. They are also called deep detectors ("see" metal at a depth of five meters).

Metal detectors with an increased range of operating frequencies. (up to several tens of kHz). It is more difficult to collect them than low-frequency. Their insightful ability to one and a half meters. Minor items are well discovered. They are rarely used due to their low technical characteristics.

How to assemble the metal detector do it yourself at home

7 simple steps:

- In order to collect the metal detector, we need a Chinese radio (must have a magnetic antenna, AM range), a cheap calculator, a box and two-way tape.

- Deploy the box to have the form of the book (on the one hand the main part, on the other cover)

- We glue the radio device and calculator to the two-way tape. (The radio is attached to the lid, and the calculator to the base).

- Turn on the receiver and find a frequency segment that is not used by radio stations (about 1.5 MHz).

- We start working with the calculator. In this case, the radio begins to make noise sharply.

- We begin slowly bring the lid of the box to the main part. We need to find a position when noise will disappear.

- Fix a book in this position. Ready! You made the simplest amateur metal. detector.

Metal detectors with discrimination of metals

Among all the metal detectors, devices that have a function of discrimination are particularly effective. What does it mean?

The metal detector not only shows the presence of an object in the primer with a characteristic field, but also displays approximate forms, dimensions and material of the found item.

Of course, with such a device, the work is much more efficient (it is not necessary to dig a soil with each detector signal) and requires less time. But such metal detectors very quickly spend energy. Plus, they are more expensive several times. For an amateur treasure detector, a cheaper analogue is suitable.

We hope that our article was useful for you, helped figure out the main types of metal search devices and maybe even suggested how to make your amateur metal detector!

Photo of metal detectors do it yourself

By their popularity, metal products are comparable with fishing or hunting, not inferior to them in Azart with a certain fraction of mercantility. Increasing the technical culture of the population and the wide range of the market for electrical destination parts contribute to the growth of the number of those who want to manufacture their own metal detector with their own hands to try themselves as a treastery. In fig. The enthusiast is shown below, using a homemade metal detector for detecting metal products on the seashore.

Principle of action of a metal detector

Metal detector (hereinafter referred to as the text of the MI), also called a metal detector, is an electronic device that shapes the directional electromagnetic field (primary signal) and capturing its changes when the field with metal objects. In the process of propagation of electromagnetic waves in an inhomogeneous physical environment, they interact with metals, creating vortex currents on their surface that generate their own electromagnetic fields. The receiving equipment of the MI fixes these fields (secondary signal) and informs the search engine about the discovered find or visual way.

How the metal detector works

The technical implementation of the principle of operation of the MI is based on the use of two basic functional elements of a modular type:

- search coils to generate a primary electromagnetic field of directional character and receiving regenerated secondary radio signals;

- control blocks for processing information from search coils and issuing processing result operator.

Depending on the purpose of mi, search coils operate in the following frequency ranges:

- low-frequency range in the range of 2.5-6.6 kHz - to detect gold, silver, copper and their alloys at a depth of 4 meters;

- in the mid-frequency range - to search for metals of any type;

- in the high-frequency range - to search for aluminum, nickel and detecting small targets at shallow depth.

The parameters of the magnetic field induced on the surface of the metal target are changed as follows:

- the amplitude of the signal is reduced by removal from the transmitter;

- the phase of the induced field is determined by the electrical conductivity of the metal.

By the difference in amplitude, the equipment of the MI calculates the distance to the target, the type of metal is determined by the phase shift.

In fig. The following is a conditional analysis scheme of information analysis.

Metal detector - detector or scanner

In essentially, detector devices are detector (from lat. Detector - detector), indicating the change in the parameters of the primary directional radio signal. The quality of metal detection directly depends on the level of complexity of the equipment of the metal detector processing the secondary signal. At the initial stage of the emergence of the operator, it was quite suitable for a squeak in headphones arising from the detection of a metal target. The development of the element base for microelectronics significantly expanded the possibilities of manual metal detection. Professional manual metal detectors are able to solve the following tasks:

- carrying out the identification of "finds" by the type of metal;

- determining the depth of its stay;

- estimation of the size and configuration of the detected item.

Using the latest software developments, the leading manufacturers launched sales with the possibilities of building an image of a detected target. For example, the German company OKM has developed a deep 3D scanner (from the English. Scan - consider) the EXR 6000 models that displayed the configuration of the metallic subject.

In fig. Below is the monitor of the MI of the EXER 6000 model with a target image displayed.

MI varieties for destination

In accordance with the target destination, mi are divided into the following types:

- Ground models designed for land surveys in the upper soil layers. The devices of this category are most common among the search for metals and treasures that can assemble the metal detector with their own hands at home. The simplest homemade has low accuracy and does not always distinguishes metals of different types. Professional devices can detect small gold grains, ignoring other metals.

- Deep models designed to detect targets at a depth of 6 meters. However, "see" they can only large objects of over 400 square meters. See deep devices in demand by engineering services as trails, geologists - as specialized georadars for sampling gold, etc.

- Underwater metal products working under water. They are presented with increased requirements for the sealing of the search engine. The conditions of the underwater in sea and fresh water differ significantly. Underwater detectors use only sound indication.

Note! Underwater can be used on surfaces in a conventional primer metal detector. Search engines need only to fit the length of the rod and the position of the stop so that it is more convenient to use the device.

- Special metal detectors:

- security devices for detecting metal products in luggage, in clothing or on the human body when inspection;

- industrial metal detectors in conveyor lines that signal the presence of metals in products;

- army devices, generalizedly called minion curbers;

- detectors configured exclusively on gold objects.

In fig. The manual inspection metal detector is shown below.

Motivation of the design of homemade metal detector

Long before collecting a metal detector at home, the craftsmen need to compare numerous factors affecting the work of MI, and choose the optimal design option in full compliance with its requests. In the manufacture of metal detector, the following technical and operational indicators are taken into account with their own hands:

- general search instrument parameters that determine its functionality;

- working frequencies, in the range of which are supposed to work;

- the search method that determines the schematic constructing of the device with a reference to the method of fixing the change in the reaction when it approaches it to the metallic object.

General parameters MI.

For homemade search equipment allocate the following parameters:

- The penetrating ability characterizing the maximum depth of the electromagnetic field penetration is deeper than which the device is no longer able to identify the metal object.

- Sensitivity indicating the ability to detect minor items.

- Resolution, more often called discrimination, giving information about the specific properties of the object. For a metal detector, a full implementation of three components of discrimination is necessary:

- geometric - for judgment about the sizes and configuration of the found target;

- spatial - for information about the depth of the target and location in the search area;

- in quality - for assumptions about the form of the material of the object and its probable characteristics.

- The sizes of the search area, within which it is possible to detect metal.

- Election is an increased reaction to the finds of a given type (gold, non-ferrous metals, military artifacts, etc.).

- Noise immunity - no reaction to electromagnetic fields of foreign sources.

- Energy consumption defining how long the active work time is enough for a mobile device power supply.

In fig. Below in ironic form shows the process of metal detection (metal) using self-made mi:

- pos. "A" - the lack of metal targets;

- pos. "B" - metal items found, representing a certain value (for which the metal-plated metal) was found.

A red sequer search zone is highlighted.

Homemade work frequencies

The metal detector circuit and its assembly tie all the parameters of the self-made metal detector to the frequency range in which the operator involves working. The practice of amateur metal showed the limited efficiency of low-frequency (VLF) and high-frequency (HF) metal detectors, requiring computer processing of signals that consume a lot of energy and poorly operating on mineralized wet soils. Most search engines interested in how to make a metal detector multifunctional to the identification and recognition of color, mushroom, with minimal susceptibility to the features of the soil, are focused on low-frequency and mid-frequency ranges ranging from 30 kHz to 3 MHz. Work in this frequency range allows the use of a simple metal detector to detect targets of any type of metals.

Search method

Methods for finding metal objects with a directed electromagnetic field there are more than a dozen, including superior digital processing on a secondary signal computer with professional use. When assembling homemade metal detectors for metal-based level, craftsmen are focused on techniques that make it possible to simplify the schematic constructing of the detector as much as possible and reduce its complete set. The most popular at the manufacture of homemade are the following metals detection methods:

- parametric method for the implementation of which the receiver is not needed;

- receiving-transmitting method - using the transmitter and receiver;

- the method with the accumulation of the phase is "before clicking";

- the method on the beats is "on a piston".

Parametric method

Parametric type metal detectors are equipped with only one coil, which is simultaneously transmitting, and receiving. When a metal target is detected, the parameters of the generating coil are changed: inductance, frequency and amplitude of fluctuations generated, which is fixed by the equipment. The main problem during the operation of the detector without receiver is considered to be the release of a relatively weak induced signal against the background of a powerful primary electromagnetic field.

Receiving-transmission method

In the design of models operating in the method "Reception", two coils are provided:

- transmitting - to generate an electromagnetic field;

- reception - to register re-energized from a metal target.

Important! When assembling receiving-transmitters, the coil must be positioned in such a way as to minimize the inductive link between them. If the axis of both coils will be mutually perpendicular, the transmitter signal will not fall directly into the receiving device and will not listen.

Metal detectors with phase accumulation (up to click)

The operation of phase sensitive instruments use the process of delaying pulses during re-emission, which leads to an increase in the phase shift. When a specific value is reached, the discriminator is triggered, click on the headphones. When approaching the metal object, clicks become increasingly, merging into the sound of a certain tonality. With the corresponding tincture of sound, the synchronization breaks directly above the object, the sound disappears due to the frequency of the movement of clicks in the ultrasonic range.

Metal detectors on the beats ("on a pisk" method)

If you do a metal detector on beats, then in the homemade design, two electromagnetic field generators are needed:

- the support generator whose frequency is stabilized and is a reference frequency parameter;

- working (search) generator, the frequency of which depends on the presence of a metal in the search area.

Before the search for search works, the search generator is configured to zero beats (frequency coincidence). When configured, a low sound tone (pisculation) is achieved to be convenient to search. By changing the tone judges the properties of the detected object and its location.

In fig. Below is shown homemade mi, made of submitted materials.

Schemes homemade Mi.

The metal apparatus of factory manufacture is presented on the market fairly expensive electronic systems of professional level, so enthusiasts are constantly exchanged information, how to make a homemade metal detector at home with minimal financial costs. Step-by-step instructions for assembling and debugging the device allows you to create a completely efficient metal detector from available radio components. Metal detectors, including the mine detector with their own hands, the scheme of which is identical to the developments for typical MI, are performed on transistors and chips. The equipment for homemade schemes also includes:

- capacitors of various types: ceramic, film, electrolytic;

- resistors;

- resonators;

- controllers.

Additional Information. Quite often, in the schemes of amateur equipment for the metal, the NE 555 chip is used, which is a universal timer generating single and repeating impulses of stable time characteristics.

A worthy competitor for metal detector on chips is a metal detector on transistors in which signal generation occurs using CT-361 and CT-315 transistors or similar radio components produced from Soviet times.

Making with your own hands composite parts

When designing self-made metal detector, the masters are guided by the creation of a small-sized, structurally balanced, relatively light product. Mobile execution and thoughtful ergonomics must minimize the operator's fatigue with many hours of continuous search engines, and the high-quality assembly of the self-made design will ensure good repeatability of the results and high operational characteristics.

Mi handicraft production consist of the following components:

- control unit;

- framework with search coil;

- the holder rods on which the search coil and control unit are attached.

Control block

To build a control unit, it is necessary to choose a plastic case of a box-type. In the case must compactly accommodate:

- a circuit board with electronic filling collected in accordance with the scheme;

- elements of power;

- devices for sound and visual notification of find.

The main element of the control unit is the printed circuit board.

Making your own handlers

The circuit board is used for compact placement of radio components that are part of the scheme. Further, a generalized description of the stages of self-making of a printed circuit board with a detailed presentation of the operations performed:

- The scheme of the metal detector is selected. In accordance with the paper on paper, it draws away from the hand or is printed on the printer sketch of the board.

- A piece of sheet text collapse is cut into the size of the board.

- In any available way, the drawing is transferred to the textolite billet.

- On the surface of the workpiece there is a markup of radio component fasteners. Holes with a diameter of 1.0-1.5 mm.

- A permanent marker or tassel with varnish draws tracks according to the paper template.

- The board is rolled with chlorine or copper vigor.

- After etching, the board is wiping and inspired by sandpaper.

- Operation is carried out by tin.

In fig. The metal detector's printed circuit board is shown below.

Frame with coil

The search frame of the metal detector is a flat hard case with a search coil attached on it, designed to perform the following tasks:

- tight fixation of the search coil relative to the holder rod;

- ensuring the constancy of the geometric dimensions of the radiating and receiving loop of the search coil;

- protection of wires of coils from damage when moving the operator for rough terrain.

The case of a circular frame or rectangular shape is made of plastic tubes without the use of metal elements. Among the craftsmen are popular PVC tubes with a diameter of the conditional passage ½ inches (15 mm). Small frames are made intimidate in the form of a ring or square. When making a large-sized rectangular body, it is appropriate to use fittings to not deform the tubes on bends. The size and shape of the housing must correspond to the size and configuration of the coil, taking into account the features of the placement of transmitting and receiving contours in it.

The most responsible search element that determines its operational characteristics is the search coil.

MI coils

The functional properties of mi are determined by the quality of the search coil. The coil parameters and the general scheme of the metal detector need a mutual fit until the optimal result is achieved. The coil performance indicators are influenced by various factors from which the following are the following:

- coil dimensions;

- constructive design of the rings of the coil;

- the magnitude of the inductance of the coil;

- degree of noise immunity;

- way of winding the wire of the basket coil;

- the method of fixing the coil.

Sizes of coil

Practice has shown that the efficiency of the coil is directly dependent on its size. Big sizes are capable of enlightening the soil and cover a wider search area than their smaller diameter analogues. The following gradation of the sizes of search coils was adopted:

- diameter 20-90 mm is optimal to search for a mushroom (fittings, profiles);

- the diameter of 130-150 mm is convenient to search for the so-called "beach gold";

- the diameter 200-600 mm is focused on overall metal objects.

Constructive design of the coil

The classic design of the search coil is a monopette (single loop), made in the form of a single flat ring from the turns of the copper wire. The width and thickness of the ring are selected 15-20 times less than the averaged ring diameter. Mi with monopettes are recommended for beginners to acquire initial search experience.

A more "advanced" design, compared to monopettes, is a DD-coil, which is a double detector (hence the name - from the English. Double Detector). A constructive DD coil is made of two semicircles folded with intersection. DD-coils have high sensitivity, but a false signal can be made on inhomogeneous soils.

Inductance coil

When assembly at home, it is very important to achieve the conformity of the parameters of the hand-made search coil with the parameters that are laid in the selected detector scheme. The magnitude of the inductance is influenced by the geometric sizes of the coil, the cross section, the number of turns, the laying density and other factors. In networks you can find various methods for calculating inductance, uncomplicated formulas and nomograms with explanations, as they use. Failure to comply with these recommendations may lead to the fact that the collected scheme will not work.

Noise resistance to the coil

Since monopette is arranged by analogy with a frame antenna, it is sensitive to numerous interference. To expand noise-resistant instrument abilities, simple devices type are used:

- faraday screen, which is a steel tube with braid or with a foil winding;

- symmetric winding of bifillar or cross-type.

Baskets coils

In fig. Below is one of the modifications of basket coils.

With all its advantages, the basket coil is endowed with two significant disadvantages:

- the complexity and complexity of the performance of high-quality reliable winding;

- methods of calculations of flat and bulk baskets differ significantly and require the use of relevant computer programs.

Important! With a handicraft winding, the ribbling coils must be rigid and durable, since the total force of tensioning all turns is large enough to deform or break the mandrel.

So that the wires are tightened when the wire winding does not cut the coil frame, it is recommended to glue pieces of durable plastic in the cutting of the frame and only after that it starts winding.

Fastening the coil

Fastening the coil wires is quite often performed on homemade frames from plywood, plastic and other girlfriends, even on computer disks. Plywood has many flaws, including:

Plastics on a polycarbonate basis of these shortcomings are deprived. Moreover, two glued polymer discs are a hermetic case that expands the possibilities of using mi.

Homemade rod holder

The holder bar is a carrier element of the metal detector - the search coil and control unit are fixed on it. The main requirement for the rod is the strength of the manufacturing material, since a permanent weight load from the operator acts on the holder during search engines. Damage to the supporting design can occur in the conditions of rough terrain, in forest stations, in the mountainous area. The breakage of the rod can lead to the forced termination of search engines.

Note!There are no certain requirements for the metal detector, each user has the right to fit the size and shape of the holder under its height and weight.

With independent manufacture of a metal detector for the hull of the holder casing, crutches under the elbow (canada) are often used as the initial semi-finished product, in the design of which the height of the rack and the implux stop is already provided. Also popular among craftsmen, telescopic rods and ordinary metal-plastic water pipes, of which are obtained full-fledged holders.

Homemade underwater metal detector

The process of manufacture, assembly and adjustment of a metal detector intended for metal detection under water is identical to the work on the creation of ordinary MI. However, it is necessary to indicate two significant differences accompanying the manufacture of underwater:

- all equipment should be placed in a hermetic case that does not allow contact with moisture to contact;

- for a message from under the found find, it is desirable to apply special light indicators.

Stages of manufacturing with their own hands underwater:

- Selection of a scheme for working in river and sea water.

- Production of printed circuit board.

- Connecting the power supply.

- Placement of the finished board with a power source in a sealed container. Masters recommend as a case to apply a tube from the sealant. LED light bulbs are displayed on the outer surface of the tube. Each joint is additionally sealed with silicone sealant.

- Production of a rod from a thin-walled stainless pipe or a conventional plastic tap pipe. Quite often use the rod housing.

Important!The bar should not be unnecessarily easy to not float, but also very heavy so as not to go to the bottom.

- Fastening the assembled block with a circuit board on the rod.

- Winding search coil. Coil housing is a standard polypropylene tube. Winched wire poured sealant.

- Soldering the conclusions of the coil to the stranded wire.

- Visual assessment of the tightness of the product. Any gaps and joints, "not inspiren confidence" on the subject of tightness, poured / lubricated with sealant.

- Verification of tightness in water.

Features of deep MI

In the work of the depths, RF-technology is used, effective in the high-frequency range. The transmitting and receiving coil is mutually perpendicular, can work at several frequencies at the same time. The deep targets are insensitive depth devices, their objects are large items located on the ground with the drops of soil levels.

If you contact the numerous forums of metal fans, which are filled with the Internet's pages, then draws attention to the high level of manufacture and adjustment of homemade structures, which is described there. Metal detectors manufactured with their own hands are not inferior to the search equipment for factory execution, although they are cheaper than cheaper. In fig. The self-made "outback" is shown below, the frame of which is made of durable polymer tubes.

Video

The device allows you to find metal objects located in a neutral medium, for example, soil, due to their conductivity are called a metal detector (metal detector). This device allows you to find metal items in various environments, including in the human body.

In many ways, thanks to the development of microelectronics, metal detectors that produce many enterprises throughout the world have high reliability and small overall-weight characteristics.

Not so long ago, such devices could most often see from sappers, now they enjoy rescuers, treasures, communal service workers when searching for pipes, cables, etc. Moreover, many "treasures" use metal detectors that they collect do it yourself .

Design and principle of device operation

Metal detectors offered on the market work on different principles. Many believe that they use the principle of impulse echo or radar. Their difference from locators is the transmitted and received signals, act constantly and at the same time, to all of the time they work on the coinciding frequencies.

Instruments operating on the principle "Reception" are recorded reflected (re-infused) from the metal object. This signal appears due to the impact on the metal object by an alternating magnetic field, which generates metal dealer coils. That is, in the design of the devices of this type, there are two coils, the first - transmitting, the second - reception.

The instruments of this class have the following advantages:

- simplicity of design;

- great features for detecting metal materials.

At the same time, the metal detectors of this class have certain disadvantages:

- metal detectors may be sensitive to the composition of the soil, in which the search for metal objects produce.

- technological difficulties in the production of the product.

In other words, the devices of this type must be customized with your own hands.

Other devices are sometimes called metal detector on beats. This name came from the distant past, more precisely since the times when super-metrogenous receivers were widely exploited. Bilation is a phenomenon that becomes noticeable when summarizing two signals with close frequencies and equal amplitudes. The beating consists in pulsing the amplitude of the amplitude signal.

The signal pulsation frequency is equal to the frequency difference difference. Skipping such a signal through the rectifier, it is also called the detector, allocate, the so-called difference frequency.

Such a scheme was used for a long time, but these days, it does not apply. They were changed synchronous detectors, but the term remained in use.

The metal detector on the beyon works using the following principle - it registers the frequency difference from two generator coils. One frequency is stable, the second contains an inductor inductor.

The device is set up with your own hands so that the generated frequencies coincide or at least were close. Once, a metal falls into the action zone, a change in the specified parameters and the frequency changes. The frequency difference can be recorded in different ways, ranging from headphones and ending with digital methods.

The devices of this class are characterized by a simple sensor design, weak sensitivity to the mineral composition of the soil.

But besides this, when they are operating, it is necessary to take into account the fact that they have high power consumption.

Typical design

The composition of the metal detector includes the following components:

- The coil is a box-type design, it has a receiver and a signal transmitter. Most often, the coil has an elliptical form and polymers are used for its manufacture. It contains a wire connecting it with a control unit. This wire transmits a signal from the receiver to the control unit. The transmitter generates a signal when the metal is detected, which is broadcast to the receiver. The coil is installed on the bottom bar.

- The metal part on which the coil is fixed and its tilt angle is configured, called the bottom rod. Thanks to this solution, a more careful study of the surface occurs. There are models in which the lower part can adjust the height of the metal detector and provides a telescopic connection with a barbell called average.

- The middle rod is a node located between the bottom and the upper rods. It fixes fixtures that allow you to adjust the device dimensions. On the market you can meet models that consist of two rods.

- The upper rod, as a rule, has a curved view. It resembles the letter S. This form is considered optimal to fasten it on hand. It is installed on it, a control unit and handle. The armrest and the handle are made of polymeric materials.

- The metal detector control unit is necessary for the processing of the data resulting from the coil. After the signal is transformed, it is sent to headphones or other means of indication. In addition, the control unit is designed to adjust the device mode. The wire from the coil is joined by a quick-release device.

All devices included in the metal detector are performed in moisture-proof.

This is such a relative simplicity design and allows you to make metal detectors with your own hands.

Varieties of metal detectors

The market presents a broad nomenclature of metal detectors used in many spheres. Below is a list in which some varieties of these devices are indicated:

Most of the modern metal detectors can find metal objects at a depth of up to 2.5 m, special depth products can detect a product at a depth of 6 meters.

Frequency of work

The second parameter is the frequency of work. The fact is that low frequencies allow the metal detector to see at a rather large depth, but they are not able to see small details. High frequencies allow you to notice small objects, but does not allow soil browsing to a large depth.

The simplest (budget) models operate at one frequency, models that refer to the average price level are used in 2 or more frequencies. There are models that, when searching, use 28 frequencies.

Modern metal detectors are equipped with such a function as metal discrimination. It allows you to distinguish the type of material on depth. At the same time, when the ferrous metal is detected in the search headphones, one sound will sound, and when the color is discovered.

Such devices refer to Ipulso - balanced. They use frequency from 8 to 15 kHz in their work. As a source, batteries are used in 9 - 12 V.

The devices of this class are able to detect a golden subject at a depth of several tens of centimeters, and products from ferrous metals at a depth of about 1 or more meters.

But, of course, these parameters depend on the device model.

How to assemble a homemade metal detector do it yourself

In the market there are many models of instruments for finding a metal in the ground, walls, etc. despite its external complexity, make metal detector with their own hands not so and difficult and can almost anyone can make it. As already noted above, any metal detector consists of the following key components - coils, decoder and a signaling device signaling device.

To assemble with your own hands, such a metal detector requires the following set of elements:

- controller;

- resonator;

- condensers of different types, including film;

- resistors;

- sound emitter;

- voltage regulator.

Metal detector simplest

The diagram of the metal detector is not distinguished by complexity, and it is possible to find it or on the expanses of the global network, or in specialized literature. The above is a list of radio elements that will be useful for assembling the metal detector with their own hands at home. A simple metal detector can be assembled with their own hands using a soldering iron or another available to the way. The main thing at the same time, the details should not touch the device's housing. In order to ensure the work of the assembled metal detector, power supplies of 9 - 12 volts are used.

For winding the coil, a wire with a cross-section diameter is used within 0.3 mm, of course, it will depend on the selected scheme. By the way, the wound coil must be protected from the impact of extraneous radiation. To do this, it is shielded with your own hands with the help of an ordinary food foil.

For the firmware of the controller, special programs are used, which can also be found on the Internet.

Metal detector without microcircuits

If a novice "treasure detector" does not have a desire to bind to chips, there are schemes without them.

There are simpler schemes based on the use of traditional transistors. Such a device can find a metal at a depth of several tens of centimeters.

Depth metal detectors are used to search for metals at large depths. But it is worth noting that they are not suiced and therefore it is quite possible to gather it with their own hands. But before proceeding to its manufacture, it is necessary to understand how a typical scheme works.

The diagram of the deep metal detector is not the simplest and there are several options for its execution. Before assembling it is necessary to prepare the following set of details and elements:

- condensers of different types - film, ceramic, etc.;

- resistors of different nominal numbers;

- semiconductors - transistors and diodes.

Nominal parameters, quantities depend on the selected device concept. To assemble the above elements, you will need a soldering iron, a set of tool (screwdriver, pliers, nippers), material for the manufacture of the board.

The process of assembling the deep metal detector looks approximately as follows. First collect control unit, the basis of which is a circuit board. It is made of textolite. The assembly scheme is then transferred directly to the surface of the finished board. After the drawing is transferred, the board must be emitted. For this purpose, a solution is used, which includes hydrogen peroxide, salt, electrolyte.

After the board is met, it needs to perform holes for installing the circuit components. After the logging of the board is performed. The most important stage occurs. Installation and soldering with your own hands on the prepared fee.

For winding the coil with their own hands, the wire of the PEV brand with a diameter of 0.5 mm is used. The number of turns and the diameter of the coil depends on the selected depth metal detector scheme.

A little about smartphones

There is an opinion that it is quite possible to make a metal detector from a smartphone. This is not true! Yes, there are applications that are installed under the Android OS.

But in fact, after installing such an application, it will really be able to find metal objects, but only pre-magnetized. Search and even more so discriminating metals he will not be able.

At the expense of its electrical or magnetic waves, a metal detector, or as it is also called the metal detector, is able to distinguish and react to metal objects hidden in another medium. This device is an indispensable assistant for the inspection service, environmentalists, builders, for "gold miners" and many other specialties. The average price of the metal detector in the Russian Federation varies from 15-60 thousand rubles. This article is designed for those who do not want to overpay, wants to independently understand the device, and make a metal detector with their own hands.

Metal detector, its device and principle

The principle of operation of the metal detector is only in words. Its essence lies in the formation of magnetic fields with the help of electrical voltage, when these most waves meet metal items on their way, the device makes a signal, notifying the find. For newbies that did not encounter such "inventions", it seems quite difficult, but if you carefully follow the instructions, it will actually be much easier. And I understand a little bit, it will be possible to easily create a device for finding an old coin at a depth of 30 cm under the ground.

Coil

In order to create a magnetic field, it is necessary that the current is passing through the riot ( bundle, winding) Copper wire with nylon insulation. It is wound on the plastic coil several times. Then wrapped with polyester, durable packaging tape. It is necessary so that the wire can not unleash back. If the bobbins are inside ( special coil) Place the pure iron, the magnetic field will increase significantly, this method is usually used for security metal detectors.

Electronic circuit

The operation of the system depends entirely on the electronic circuit, this is the brain of the device. The remaining piece of copper wire is soldered to the printed circuit board, another boot output is connected by electrical wiring to the sensors: LEDs, vibrators, speakers. In the event of a collision of magnetic waves with a metal, the electrical signal will come from the coil to indicators through the fee. Perhaps this is the most difficult part of the creation of the device with your own hands. Then the device is calibrated, adjust, placed in a plastic protective case.

Main settings

According to its properties, metal detectors are divided into basic 3 groups: deep, underwater, soil. By the name immediately understand what their features are. Although it is often created by hybrids, for example, the ground is a waterproof coil with a housing. Naturally, these will cost an order of magnitude higher. To make a metal detector itself, you need to clearly represent, for what purposes it will be used, based on this there are general parameters of the device:

- The depth of action underground, each device has its own "penetrating ability." Of course, it also depends on the density, kind of soil, the presence of stones in it, but it is already secondary.

- The diameter of the search zone, you must immediately determine which range will be optimal, and from it to repel, choosing, or collecting the metal detector.

- Metal sensitivity. Here, the question arises, for what purpose the device will be used: for the treasures, the little thing will only interfere, but for hunters for lost decorations on the beach, it is important not to miss anything, even the smallest thing.

- Metal selectivity. There are devices that react only to certain precious alloys.

- Power and energy saving, standard characteristics of any wireless device.

- At all new models, there is such a feature as "discrimination", which allows the device to display an approximate depth, location, metal alloy.

Depth of detection

On average, the depth of search from the metal detector ranges from 1 to 100 centimeters. Different models, have different accuracy and depth of action. Basically, visibility range depends on the size of the coil than it is more, the deeper you can look. And the very first mistake of most newcomers, not knowing why, not knowing why, they choose a metal detector with the greatest depth of the study. On average, vintage coins are buried for 30-35 centimeters, and lost precious decorations even closer to the surface. In addition, the more depth, the greater the errors and mistakes. You can dug 10 holes in a depth of 1 meter, in the same time finding really something valuable almost on the surface, absolutely not bored.

Frequency of work

Like any device, the metal detector has the relationship of its components. Using the device at full power, you increase the energy efficiency of the battery. If we consider the metal detector as a whole, we can conclude that all its components are dimensions and functionality depend on the frequency of the generator. This is perhaps the most important evaluation criterion, according to which they are classified:

- The first option is absolutely not amateur - ultra-low-frequency. Without certain computer support, he will not be able to work. Following the coil, a special machine must follow, which will not only process the signal to the operator, but also to supply the charge due to considerable energy costs. Its range is less than 100 Hz.

- The second option is also not a simple household appliance - low-frequency. The range varies from 100 Hz to 10 kHz. Also requires large energy consumption, mainly calculated on the search for ferrous metals with a depth of 5 meters. It requires computer processing of signals, but even with its help, it has a greater error in the recognition of the alloy and its volume at high depths.

- Universal, more complicated, compact - high-frequency metal detectors. With the help of such a device, you can find a metal of 1.5 meters deep. It has an average noise immunity, but good sensitivity, at a small depth, is the ability to determine the alloy and the size of the metal, with quite good accuracy. It has a range of up to 30 kHz.

- Radiofrequency metal detectors, they probably saw each, standard device suitable for consistent lovers. It has excellent discrimination with a depth of 0.5 meters. If the soil does not have magnetic properties, for example, sand, or there is no radio or television station, then it is just an excellent universal apparatus. It is very small in comparison with representatives above. And its full efficiency will also depend on its components, in many respects from the coil.

Assembling metal detector with his own hands

In the Internet space, a large number of schemes, video, forums, tips on the assembly of metal detector. And among the many reviews, there are many negative about the apparatus of our own production. Many people write that they did not work, it does not work that it is better to buy a lot of time to sell ... Answer similar comments is very simple: if you go to the goal, and approach the question seriously, then the production of your own hands will be much better than factory metal. If you want to do something good, do it yourself.

Is it possible to make a metal detector with your own hands?

A person who knows at least at the school level and is interested in physics and electronics, such a task will not be much difficult. And the case will remain only for the selection of quality materials. But beginners should not retreat, step by step, following the instructions, adding a little perseverance, everything will certainly succeed.

Independent manufacture of printed circuit board

The most difficult stage in the assembly of the detector - the manufacture of printed circuit board. Since this is the brain of the whole design, and without it the device simply will not work. Take to begin with the simplest manufacturing technology - laser-iron.

- Initially, we will need a scheme, of course on the Internet their huge amount. But if a person set the goal to do everything himself, a special Sprint-Layout program will come to the rescue, which will help you develop it.

And so, having a ready schematic pattern of the board, we print it with a laser printer, it is important, on the photo paper. Many recommend using a small paper density to better manifest items. - Purchase a piece of textolite, it will not be difficult to find it, and prepare it properly:

1) Cut with metal scissors (or metal knife) from a piece of textolite, the workpiece according to the size we need and the respective printouts.

2) Then you need to clean the workpiece from the top layer using the sandpaper. The perfect result is a uniform mirror shine.

3) wetting a slice of a rag in alcohol, acetone, or a different solvent, and carefully wipe. This is required to degrease and clean our harvesting material. - After the procedures done, we put on the textolite photo paper with the printed scheme, and smoothed the hot iron to ensure the translation of the picture. Then you should slowly immerse the workpiece into warm water, and very carefully and, carefully, without lubricating the pattern, remove the paper. But even if the outline smeared a little, not trouble, you can adjust it with a needle.

- When the board snacks a little, the next stage comes, for which we need a solution of copper mood or chlorine iron.

To prepare this solution, you need to purchase chlorine iron powder (FECL3). In a radio shop, it costs completely a penny. We divor into this powder with water, in the ratio of 1 to 3. The water should be not hot, and the dishes should not be made of metal.

Immerse our fee into the solution for a while, depending on the thickness of the material and external conditions, there is no certain time. If it is intermitted periodically solution, the process will pass faster and better. - We take out the fee, rinse under running water, remove the toner with alcohol or any other solvent.

- With drills, we make holes for the details where they are needed according to the scheme.

In more detail with this method, you can find our article:

Installation of radio components on the fee

At this stage it is required to provide a fee with all the necessary radio components. Do not be afraid of complex names, unknown combinations of numbers and letters. All items are signed. You just need to find suitable, buy them, mow in your place.

Here is a fairly simple example, but effective in using scheme -pirate

So, let's begin:

- As the main chip, it is quite possible to take an inexpensive CR1006V1, or its various foreign analogues, for example - NE555, it is used on the scheme provided above. To install the circuit on a fee, it is necessary to pour a jumper between them.

- The next step, install the amplifier, for example, K157UD2, which is also specified in the diagram above. By the way, rushing in the old Soviet devices you can find this and many other details.

- Then we set two SMD components (they look like small bricks) and mount the MLT C2-23 resistor.

- By installing the resistor, you need to stop two transistors. Very important moment for beginners: The structure of the first must correspond to NPN, and the other PNP. Ideally, BC 557 and BC 547 are ideal for this instrument, but since they are not so easy to find, various foreign counterparts can be used. But the field transistor is well suitable for IRF - 740, or any other with the same parameters, in this case it is not important.

- The last step will be the installation of capacitors. And immediately advice: it is best to choose with the lowest TKE value, it significantly improves thermoregulation.

Manufacturing coil

As already written earlier, manufacturing the self-made coil, it is necessary to wind up approximately 25-30 turns of the PEV wire, if its diameter is 0.5 millimeters. But it is best to test the device in the case, select and change the number of turns to achieve the desired result.

Frame and Additional Elements

To recognize the finding of the device, you can use any speaker with zero resistance. As a power supply, you can use a battery or simple batteries with a common voltage of more than 13 volts. For greater stability and electrical equilibrium of the circuit, the output stabilizer is mounted. For a pirate scheme, the ideal voltage will be L7812.

Making sure that the metal detector, we turn on the fantasy and create a frame that will be primarily a convenient operator. There are several delight tips, to create a case:

- The fee must be protected by placing it in a special box, firmly fixing it in a fixed state. The box itself is placed by convenience on the frame.

- When creating the case, it is necessary to take into account one point: the more metal objects will be present in the design, the less sensitive will be the device.

- To ensure the device with all sorts of comfort, such as armrest, you can use a piece of sawn tap pipe in half. Below to attach a rubber handle. And on the upper part, to build some additional holder.

Schemes of the most popular metal detectors

Butterfly scheme

Scheme Koschey

Scheme quasar

Chance Scheme

Best Metal Detector

Why was Volksturm called the best metal detector? The main thing is the scheme really simple and really working. From a variety of metal detectors schemes that I personally did, it is here that everything is simple, deep and reliably! Moreover, with its simplicity, in the metal detector there is a good discrimination scheme - the definition of iron or non-ferrous metal is in the ground. The assembly of the metal detector consists in an error-free solder of the board and setting the coils into the resonance and at zero at the output of the input stage on the LF353. There is nothing superser, there would be a desire and brains. We look constructive metal detector execution and a new enhanced Volksturm scheme with a description.

Since, in the course of the assembly, questions arise to save your time and not to force the hundreds of pages of the forum, here are answers to the 10 most popular questions. The article in the process of writing, so some items will be supplemented later.

1. Principle of operation and detecting the goals of this metal detector?

2. How to check whether a metal detector work works?

3. What resonance to choose?

4. What condensers are better?

5. How to set up resonance?

6. How to cut coils in zero?

7. What wire for coils is better?

8. What are the details and what can be replaced?

9. What is the depth of the search for goals?

10. Nutrition of the Volksturm Metal Detector?

The principle of operation of the Volksturm Metal Detector

I will try in two words about the principle of operation: transmission, reception and balance of induction. In the search sensor of the metal detector, 2 coils are installed - transmitting and receiving. The presence of a metal changes the inductive link between them (including phase), which affects the received signal, which is then processed by the indication unit. Between the first and second chip, the switch controlled by the generator shifted by phase relative to the transmitting channel (i.e., when the transmitter works, the receiver is turned off and on the contrary if the receiver is turned on the transmitter rests, and the receiver calmly catches the reflected signal in this pause). So, you turned on the metal detector and it beeps. Excellent, if stamps - it means many nodes work. Let's figure out why it is stamping. The U6B generator constantly generates a tone. Next, it enters the amplifier on two transistors, but the UHH will not open (will not miss the tone) until the voltage at the y2B (7th output) will not allow it. This voltage is set by changing the mode using this very resistor TRACH. They need to set such tension so that the UHR almost opened and missed the signal from the generator. And the input pair of Milvololt from the metal detector coil, passing the amplifying cascades, will exceed this threshold and it will open completely and the speaker will be discovered. Now let's follow the passage of the signal, or rather the response signal. At the first cascade (1-U1A) there will be a pair of Milcivolt, you can up to 50. On the second cascade (7-U1B), this deviation will increase, on the third (1-U2) will already be a couple of volts. But without a response everywhere at the outputs at zeros.

How to check whether the board is working

In general, the amplifier and key (CD 4066) is checked with a finger at the RX input contact with the maximum Sens resistance and the maximum background on the dynamics. If the change in the background is when pressing a finger for a second, the key and the operating rooms work, then connect the RX coils with the circuit condenser in parallel, the condenser on the TX coil sequentially, we give one coil to another and begin to reduce in 0 by the minimum AC indication on the first leg of the amplifier U1A. Next, we take something big and iron and check there is a reaction to metal in the dynamics or not. We will check the voltage on the U2B (7th output) it should be a trash regulator, change + volt. If not, the problem is in this Cascade of OU. To start checking the board, turn off the coil and turn on the power.

1. Must go sound when the sensor regulator is positioned on the maximum resistance, totto the finger on the Px - if there is a reaction, all the operatingors work, if not, we check the finger starting with U2 and change (survey the strapping) of non-working OU.

2. The generator operation is verified by the frequency meter program. Plug from headphones soldered to 12 withdrawal CD4013 (561TM2) prudently dropping P23 (so that the sound card does not burn). In the sound card to use in-lane. We look at the generation frequency, its stability is 8192 Hz. If it is strongly shifted, then the C9 capacitor should be harvested, if after it is not clearly highlighted and / or a lot of frequency bursts nearby - replace quartz.

3. Checked amplifiers and generator. If everything is fine, but still does not work - change the key (CD 4066).

What resonance to choose

When connecting the coil into a serial resonance, the current in the coil and the overall consumption of the circuit increases. Increases the distance detection distance, but it is only on the table. On the real soil, the earth will feel the stronger than the larger the pumping current in the coil. It is better to turn on parallel resonance, and raise the input cascades. Yes, and the batteries are enough much longer. Despite the fact that consistent resonance is used in all branded expensive metal plates, in the storm you need it precisely parallel. In imported, expensive devices, good configuration schematics from the ground, therefore, in these devices can be allowed to be allowed.

What condensers are better to install in the scheme metal detector

The type of capacitor connected to the coil is not when, and if it was experimentally changed two and saw that with one of them the resonance is better, then it is simply one of the supposedly 0.1 μF really has 0.098 Igf, and the other 0.11. So the difference between them in resonance is obtained. I used Soviet K73-17 and green imported pillows.

How to set up resonance coils metal detector

The coil, as the best option, is obtained from plastering grads glued with epoxy resin from the ends to the size you need. Moreover, its central part with a piece of the handle of this very grater, which is processed to one wide ear. On the bar, on the contrary, the fork of two bunches of fastening. This solution allows you to solve the problem of deformation of the coil, when tightening the plastic bolt. The windings for the windings make the usual delicate, then setting the zero and fill. From the cold end TX, we will leave 50 cm. Wires, which originally not to fill, and press the small coil from it (with a diameter of 3 cm) and place it inside the RX, moving and deforming it in small limits, you can achieve an accurate zero, but to do it It is better on the street by placing the coil at the Earth (as when searching) with the geb disconnected if it is, then finally pour the resin. Then the detuning from the Earth, it works more, less tolerable (the exception is strongly mineralized soil). Such a coil is obtained easy, durable, little prone to thermodood, and treated and painted very pretty. And one more observation: if the metal detector is assembled with downtown (GEB) and under the central location of the resistor's engine to set zero a very small washer, the geba adjustment range is 80-100 mV. If you set the zero large subject of a coin 10-50 kopeck. The adjustment range increases to + - 500-600 mV. For voltage in the process of adjusting the resonance, do not chase - I have about 40V with a 12V power with a consistent resonance. To discriminate, condensers in the coils turn on in parallel (the sequential inclusion is only needed at the selection stage for resonance) - on ferrous metals there will be a long sound, color - short.

Or even easier. We connect the coils in turn to the transmitting TX output. We configure one in the resonance, and configuring it - another. Step by step: they connected, parallel the coil was twisted by a multimeter at the limit variables, the condenser 0.07-0.08 ICF soldered the coil parallel to the coil, see the testimony. Suppose 4 V is very weak, not in resonance with a frequency. Pressed parallel to the first condenser of the second small capacity - 0.01 μF (0.07 + 0.01 \u003d 0.08). We look - already showed a voltmeter 7 V. Excellent, we will increase the container, connect to 0.02 μF - we look at the voltmeter, and there are 20 V. Great, we are going on - another dock is a couple of thousand peaks of tanks. Yeah. Already the beginning fall, roll up back. And so to achieve maximum voltmeter readings on a metal detector coil. Then, similarly on the other (reception) coil. Configure maximum and connect back to the receiving socket.

How to reduce metal dealer coils in zero

To adjust zero, we connect the tester to the first leg LF353 and we begin to compress, stretch the coil. After the epoxy bay - Nolik will definitely run away. Therefore, it is necessary to pour not the whole coil, but leave space for adjustment, and after drying, bring to zero and pour finally. Take a piece of twine and half the coil to tie in one turn to the middle (to the central part, the place of connecting two coils) insert a piece of a piece of sticks after which it is twisted (pulling the twine) - the coil will shrink, catching the spike sponge to be powered by glue Again, to adjust the nolik by turning the wand more slightly and pour the twine finally. Or easier: the transmitted is fixed in plastic stationary, and the reception is superimposed on the first 1 cm, such as wedding rings. At the first pin, U1a will be a peak of 8 kHz - can be controlled by a voltmeter of alternating current, but better just high-level headphones. So the receiving coil of the metal detection must be shifted, then shifted with transmitting until the output of the OU does not appeal to a minimum (or the testimony of the voltmeter will not fall to several milcialt). Everything, the coil is reduced, fix.

Which wire for search coils is better

Wire for winding coils does not matter. From 0.3 to 0.8 there will be any, it will still have to pick up the capacitance to adjust the contours to the resonance and the frequency of 8.192 kHz. Of course, a thinner wire is quite suitable, just what it is thicker, the kindness and, as a result of a little - better. But if you wind 1 mm - it will be quite hard to carry. On a sheet of paper, we draw a rectangle 15 to 23 cm. From the left upper and lower angle, we deposit 2.5 cm, and connect their line. We also do the same with the right top and bottom corners, but we post 3 cm. In the middle of the bottom we put the point and on the point left and right at a distance of 1 cm. We take Phaneur, we put this sketch and drive the carnations to all points specified. We take the wire of the PEV 0.3 and wind 80 turns of the wire. But honestly, no difference how many turns. All the same, the frequency of 8 kHz will be exhibited in a condenser resonance. How many wounds - so much wound. I wind 80 turns and a condenser 0.1 of the ICF, if you wog up 50 - the container, respectively, somewhere 0.13 μF will have to have. Next, without removing from the template, wind the coil is thick thread - such as wiring harnesses. After covering the coil with varnish. When dried, remove the coil from the template. Then there is a winding of the coil with insulation - FUM tape or tape. Next is the winding of the foil coil of the coil, you can take a ribbon from electrolytic capacitors. TX The coil can not be shielded. Do not forget to leave the gap in the screen 10 mm, in the middle of the coil. The foil winding is on the tinned wire. This wire, along with the initial contact of the coil, we will have a mass. And finally winding the coil with a tape. The inductance of coils is about 3.5 mg. Capacity is about 0.1μF. As for the fill of the coil epoxy, I did not stick it at all. Just tightly climbed the tape. And nothing, two seasons went away with this metal detector without setting. Pay attention to the moisture insulation of the circuit and search coils, because you will have to mock the grass. Everything should be hermetically - otherwise the moisture will fall and the setting will float. Worsen sensitivity.

What details and what can be replaced

Transistors:

BC546 - 3pcs or kt315.

BC556 - 1pc or kt361

Operations:

LF353 - 1pcs or change to a more common TL072.

LM358N - 2pcs

Digital microcircuits:

CD4011 - 1pc

CD4066 - 1pc

CD4013 - 1pc

Resistors permanent, Power 0.125-0.25 W:

5.6K - 1pc

430K - 1pc

22K - 3pcs

10K - 1pc

390K - 1pc

1k - 2pcs

1.5K - 1pc

100K - 8pcs

220K - 1pc

130K - 2pcs

56k - 1pc

8.2K \u200b\u200b- 1pc

Resistors variables:

100K - 1pc

330K - 1pc

Capacitors are notolar:

1NF - 1pc

22nf - 3pcs (22000pf \u003d 22nf \u003d 0.02222222222

220NF - 1pc

1MKF - 2pcs

47NF - 1pc

10nf - 1pc

Electrolytic condensers:

220MKF on 16V - 2pcs

The dynamic miniature.

Quartz resonator on 32768 Hz.

Two supermarket LEDs of different color.

If you can not get imported chips, here are the domestic analogues: CD 4066 - K561T3, CD4013 - 561TM2, CD4011 - 561L7, LM358N - kr1040ud1. The LF353 chip is there is no direct analogue, but boldly put LM358N or better TL072, TL062. It is not necessary to put the operational amplifier precisely - LF353, I simply raised the reinforcement on the U1A replacing the resistor in the negative feedback circuit of 390 kΩ per 1 mΩ - sensitivity increased significantly by percentage of 50, though after this replacement gave zero, I had to glue the coil in a certain place Scotch tape slice of aluminum plate. Soviet three kopecks feels over the air at a distance of 25 centimeters and this is 6 volts when nutrition, the current consumed without indication is 10 mA. And do not forget about the panels - convenience and simplicity settings will increase significantly. CT814 transistors, KT815 - to the transmitting part of the metal detector, CT315 in UH. Transistors - 816 and 817 It is desirable to choose with the same gain coefficient. Replace on any appropriate structure and power. In the metal detector generator, a special hour quartz is installed at a frequency of 32768 Hz. This standard is absolutely for all quartz resonators, which are in any electronic and electromechanical clock. Including wrist and cheap Chinese wall / desktops. Archives with a printed circuit board for the option and for (option with manual detuning from the Earth).

What depends the depth of the search for goals

The greater the diameter of the metal dealer coil, the more deeply. In general, the depth of detection of the target with this coil depends primarily on the size of the target itself. But with an increase in the diameter of the coil, there is a decrease in the accuracy of the detection of the object and even sometimes loss of small goals. For objects with a coin, this effect is observed with an increase in the coil size over 40 cm. Total: a large search coil, has a greater depth of detection and greater capture, but less accurately detects the target than the small one. The big coil is ideal for finding deep and large goals, such as treasures and large objects.

The coil shape is divided into round and elliptic (rectangular). The elliptical coil of the metal detector has the best selectivity compared to the round, because it is less than the width of the magnetic field and there are less extraneous objects in its field. But the round has a greater depth of detection and better sensitivity to the goal. Especially on weakly mineralized soils. The round coil is most often used when searching with a metal detector.

The coils with a diameter of less than 15 cm are called small, the coil with a diameter of 15-30 cm is called medium and coils over 30 cm - large. The big coil generates a greater electromagnetic field, so it has a large detection depth than small. Big coils generate a large electromagnetic field and, accordingly, have a greater depth of detection and coating when searching. Such coils are used to view large areas, but when using them, there may be a problem on highly messenger sites because in the field of the action of large coils can be caught several goals and the metal detector will react to a larger goal.

The electromagnetic field of a small search coil is also small, so with such a coil is best to search in the territories highly lit for all sorts of small metal objects. The small coil is ideal for detecting small objects, but has a small area of \u200b\u200bcoating and a relatively small detection depth.

For universal search, medium coils will fit well. This search coil size combines a sufficient depth of search and sensitivity to goals with different sizes. I made every coil with a diameter of about 16 cm and both of these coils laid in a round stand from under the old monitor 15. "In this embodiment, the depth of this metal detector will be the following: aluminum plate 50x70 mm - 60 cm, nut M5-5 cm, coin - 30 cm, bucket - near the meter. These values \u200b\u200bare obtained in air, in the ground will be 30% less.

Metal detector power

Separately, the metal detector scheme pulls 15-20 mA, with a connected coil + 30-40 mA, and there is up to 60 mA. Of course, depending on the type of dynamics used and LEDs, this value may vary. The simplest case - the power took 3 (or even two) consistently connected lithium ion batteries from Mobile by 3.7V and during charge of discharged batteries, when you connect any power supply to 12-13V, the charge current starts from 0.8A and drops to 50m An hour and then do not need to add something at all, although the restrictive resistor of course does not prevent. As general, the most simplest option - Krona on 9V. But note that the metal detector will eat it in 2 hours. But to configure this power option. Crown under any circumstances will not give a large current that can burn something in the board.

Homemade metal detector

And now a description of the metal detector assembly process from one of the visitors. Since I have only a multimeter from the devices, I downloaded the virtual laboratory of records OL. Assemmed the adapter, a simple generator and drove into a single oscilloscope. It seems like some picture. Next, I started searching for radio components. Since the sizes are mostly laid out in the "Lay" format, Sprint-layout50 downloaded. I found out that such a laser and ironing technology of manufacturing printed circuit boards and how to train them. Put the board. By this time, all microcircuits were found. What I did not find in my shed, I had to buy. I began to solder jumpers, resistors, microcircuit sockets, and quartz from the Chinese alarm clock on the fee. Periodically checking the resistance on the power tires so that no snotes were. I decided to start collecting the digital part of the device as the easiest. That is a generator, divider and switch. Collected. Put the generator chip (K561L7) and the divider (K561TM2). B / ear microcircuits, out of some boards discovered in the shed. Submitted power 12V controlling current consumption by amermeter, 561TM2 became warm. Replaced 561TM2, filed food - zero emotions. We measure the voltage on the legs of the generator - on 1 and 2 legs of 12V. I change 561l7. I turn on - at the exit of the divider, there are generation on 13 legs (I observe on a virtual oscilloscope)! The truth is not so good, but for the absence of a normal oscilloscope - will go. But on 1, 2 and 12 legs there is nothing. So the generator works, you need to change TM2. Installed the third chip of the divider - beauty at all outputs is generation! For myself, I concluded that the chips need to be filled as careful! This is the first step of the building made.

Now configure the metal detector's fee. The "SENS" regulator did not work - sensitivity, I had to throw out the C3 capacitor after that the sensitivity adjustment earned as it should. I didn't like the sound that occurs in the extreme left position of the "Thresh" regulator - threshold, got rid of this replacing the resistor R9 with a chain of a successively connected resistor by 5.6 kΩ + condenser by 47.0 μF (negative condenser withdrawal from the transistor). While there is no LF353 chip instead of her LM358, the Soviet three kopecks feels with it at a distance of 15 centimeters.

I turned on the search coil on the transmission as a sequential oscillating circuit, and on the reception as a parallel oscillating circuit. Called the first transmitting coil, connected the collected design of the sensor to the metal detector, the oscilloscope parallel to the coil and at the maximum amplitude, the capacitors picked up. After that, the oscilloscope connected to the receiving coil to the receiving coil and at the maximum amplitude, the condensers were picked up on RX. The adjustment of the contours in the resonance takes, in the presence of an oscilloscope, a few minutes. TX and RX windings in me contain 100 turns of the wire with a diameter of 0.4. We start mixing on the table, without a case. Just so that there were two wrap with wires. And to make sure that work and the possibility of information is generally - the collapse of the coil from the DRA half the meter. Then zero will be accurate. Then impoverish the coil of the flask about 1cm (as wedding rings) shift - to move away. The zero point can be quite accurate and catch it immediately difficult. But it is.

When, I raised the reinforcement in the RX path of MD, he began to work unstable on the maximum sensitivity, this was manifested that after passing over the goal and its detection was given a signal, but it continued and after the goals before the search coil did not have any manifested in the form of intermittent and oscillating sound signals. With the help of an oscilloscope, the reason for this was found: during the operation of the dynamics and a minor feeding drawdown of the supply voltage, "zero" and the MD scheme goes into an auto-oscillating mode, to exit from which you can only download the triggering threshold. It did not suit me therefore I put it on the food of KR142EN5A + over the bright white LED to raise the voltage at the output of the integral stabilizer, the stabilizer to a higher voltage was not in me. Such an LED can be used even to illuminate the search coil. The speaker connected to the stabilizer, MD after that it became immediately very obedient all began to work as it should. I think the Volksturm is really the best homemade metal detector!

Recently, this scheme has been proposed, which will allow us to turn Volksturm S in Volksturm SS + GEB. Now the device will have a good discriminator as well as the selectivity of metals and tuning from the soil, the device rolls on a separate board and is connected instead of C5 and C4 capacitors. The scheme of refinement and in the archive. Separate thanks for information on the assembly and configuration of the metal detector to everyone who participated in the discussion and modernization of the scheme, especially helped in the preparation of the material of the electrocity, festka, XXX, SLAVAKE, EW2BW, REDKII and other radio amateurs colleagues.

Magnetometry in the simplest version The ferrozond consists of a ferromagnetic core and two coils on it

Magnetometry in the simplest version The ferrozond consists of a ferromagnetic core and two coils on it Effective job search course search

Effective job search course search The main characteristics and parameters of the photodiode

The main characteristics and parameters of the photodiode How to edit PDF (five applications to change PDF files) How to delete individual pages from PDF

How to edit PDF (five applications to change PDF files) How to delete individual pages from PDF Why the fired program window is long unfolded?

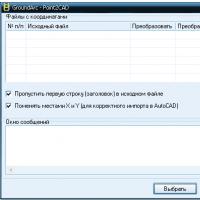

Why the fired program window is long unfolded? DXF2TXT - export and translation of the text from AutoCAD to display a dwg traffic point in TXT

DXF2TXT - export and translation of the text from AutoCAD to display a dwg traffic point in TXT What to do if the mouse cursor disappears

What to do if the mouse cursor disappears