How to measure the central hole of the disk. Bosrauto - Cars from Germany. Technical information. Complete and abbreviated formula

If you have not found data on your car, you can measure them yourself. To properly pick up the disk you need to know the six basic disk parameters:

But in order not to measure all parameters, some of them can be read in the instruction manual according to your car or on a spare wheel if the machine is equipped with a cast (from aluminum alloy) a full-size spare wheel (the same as all other wheels that stand on the car ).

To do this, remove the wheel from the trunk and read the inscriptions on the inside of the disk.

If your car is equipped with a "sink", then you need to remove one wheel from the car if there are "cast" discs.

Attention! All contents of this site are protected by law on intellectual property (Rospatent, certificate of reg. №2006612529). Installation of the hyperlink to the materials of the site is not considered as a violation of rights and harmonization does not require. Legal support of the site - JUR Firm "Internet and Law".

Sometimes car owners face the need to replace the discs on their car to new ones. But it is only worth come to the store, car enthusiasts are immediately lost, such a large assortment of wheels is presented in them. Choose something specific is not possible. When choosing disks, you need to consider a huge number of parameters. One of them is the diameter of the center opening of the disk. About what it is what it affects what characteristics it is better to choose for your car, you can learn from this article.

What parameters need to know when selecting disks?

At first glance it may seem to choose new Disc For your wheel is easy. But then you are encountered with the designations of the following type: 4 * 108, 6s ET47, DIA 62.5, R17. Yes, it is in this form that everything is indicated. specifications. Because disks have many parameters that need to be considered when purchasing. What do they turn on to themselves?

- Disc type: cast or stamped.

- Fastening holes: number and diameter.

- Shape of the hub.

- The diameter of the central hole (hub).

- Diameter of the circle of the disk.

If these nuances seem unnecessary, then help you will be able to in any wheeled store. If you want to figure out in all parts yourself, we will try to understand what is the diameter of the central opening of the disk. What is this?

What is the diameter of the central opening of the disk?

This is a hole in the middle of the disk, which, despite its seeming simplicity, determines a lot of car parameters. In the wheel characteristics list, it is usually marked as Dia or simply D. Do not confuse it with the designation of the PSD, which indicates the magnitude of the mounting holes. The diameter of the central opening of the disk must accurately correspond to the diameter of the planting cylinder on the hub. Often, the same and the same discs are released at once for several car brands, so before buying it is necessary to check the compliance of this parameter to the manufacturer's technical characteristics. The disk can incorrectly stand, it is loose, because of which you will constantly feel the vibration and the uneven move of the wheel. It is even better to buy original spare parts. If there is no such possibility, then carefully examine the size of the central opening. Usually the deviation is allowed in 2-5 mm on cast discs and 0.01 mm on the stamped.

What parameters affect the central hole?

Contemporary wheelbarriers faced with huge number Stamps and models with different parameters. Naturally, producing discs individually for each car would be meaningless and very expensive. Therefore, companies go along the path of least resistance: they produce wheels with the highest possible central hole. And this is not very well affecting the behavior of the car, especially at high speeds. What other parameters affect this hole?

- Uniform wear of tires. The choice of disk with the "wrong" central opening can lead to uneven wiring of the tires. Due to the wrong load distribution, the tread pattern can be labeled only on the one hand, which will eventually affect other characteristics of the machine.

- Tire life. From right choice It also depends on how much you can drive on a new set of rubber. Properly chosen discs increase the service life of the tires.

- The service life of the steering wheel. If the machine has developed a fairly high speed, and Dia is incorrectly selected, the steering wheel starts to "beat", which in the end leads to its breakdown.

- Body vibration. If at speeds above 80 km / h, your car has become "shook", then, most likely, the problem lies precisely in the diameter of the central opening of the cast disc.

What if the central hole of the disk is larger than the diameter of the hub?

All disc sellers recommend checking them on the car before purchase, while it is desirable to drive at them at least a small segment of the path. It is even better to accelerate the speed of 60-80 km / h to understand exactly how new wheels behave. Put on the car discs with a central diameter less than the diameter of the hub is difficult. Is it possible to put the wheels with a large diameter? Of course, it is best to pick a hole perfectly suitable for your car. If there is no such possibility, you can set the so-called universal disc, with a large central hole. To do this, you need to purchase a set of transition rings that will compensate for the difference between the hub and the disk. Carefully make sure that they are not damaged during and that they all the time put back after the seasonal change of the wheels. If you fit the disks, do not forget to follow, there are no rings on the hub from previous drives.

Pros and disadvantage of central hole

What does the central hole affect and will change technical specifications car when it is magnified? To the positive parties of the disk with a universal central diameter include:

- Availability - Such discs can be found everywhere. As a rule, they are released for a large number of brands and models, so it is not necessary to choose it.

- Universality - discs with a large central hole fit for many models.

- Price - as such goods make in large parties, the price of it is slightly lower than on "exclusive" chosen discs.

But not only with the pros, you can encounter if you select a disk with an increased central diameter. There is such a choice and not very pleasant consequences:

- At high speeds due to a loose fit of the disk to the hub, the car begins to "beat". Observe this unpleasant phenomenon can only replace the disks.

- At the most worst case, if you incorrectly picked up the disk and did not put the spacer rings, the wheel can break out the carving on the nuts. This is an extreme option, but still it happens if you neglect the safety rules.

Hub diameter for different cars

Each car has its own list of permissible plant diameters. Parameters may vary, usually you can learn them in a sticker next to the driver's seat or from the technical characteristics of the machine. The variety of diameters of the central opening sometimes introduces buyers in bewilderment. They differ sometimes literally 0.1 mm. There are no uniform standards, so some manufacturers indicate the data more accurately, while others are less. Some self-respecting disk manufacturers go further and indicate indicators not 1/20 millimeter, but to as many as 10 microns, i.e. up to 0.01 mm. What are the standards taken for the most popular brands?

- The diameter of the central opening of the disc from the "Vase" will be 58.6 mm.

- The same indicator of "Audi" is 57.1 mm.

- The diameter of the central hole of the disk at Honda is 64.1 mm.

- "BMW" has a hub diameter ranges from 74.1 to 72.6 mm.

- In Citroen cars, the indicators also differ - you can find machines with a central hole diameter of 65.1 and 58.1 mm.

- Fords have scatter size as well as large: 57.1; 63.4 and 64.1 mm.

The diameter of the central opening for "Niva"

Domestic cars "Niva" have quite wide hubs. The diameter of the central opening of the disk at "Niva" is about 98.5 mm or 3 and 7/8 inches. What car discs can come to this car if you buy original capabilities?

- Niva Chevrolet;

- Volga (gas 31024, 29), different years of release;

- or jimni.

Diameter of the central opening Renault Logan

Owners of the Renault Logan car brand when choosing discs often wonder what parameters select among the variety of assortment? For Renault Logan disks, the diameter of the central opening should be at least 60.1 mm. At the same time, their radius is better to select with R14 and higher indicators. For such conditions, many wheeled discs are suitable, which highly simplifies the task for drivers.

When buying wheel drives, experts advise pay attention to the following details:

- If you buy a stamped disk, be very careful when selecting parameters. Even a deviation of 0.1 mm will be critical: transition rings are not used for steel disks, so you can't ride on such wheels.

- The diameter of the central opening on alloy wheels can be easily determined using a special reservoir ring. With him, you will learn exact parameters without resorting to assistance.

- If you purchase original disks for your car, then no transition disks will be required. As a rule, such a product is manufactured precisely under the parameters of the wheel opening of a certain brand.

Wheel disk is one of the components of the car wheel elements. It serves as the basis for fastening, as well as to transmit torque on it from drive shafts. Depending on the technology and the material used, several types of wheels are distinguished, each of which has both advantages and disadvantages. And wheelcase parameters, such as their diameter, width and other indicators determine the choice in favor of one or another option.

Purpose and design of wheels

Car wheel designWheel discs besides what improves the appearance of the wheel, are also a necessary element for the movement of the car along the road. The tire itself is dressed directly on them. And the disk with the tire mounted on it is a car wheel fixed on the hub.

The bus on the disk is fixed due to the annular protrusion. Tire board is located on the shelf, characterized by three dimensions: standard, flat and extended. Landing tires, as a rule, occurs on the outer shelf. The shelf smoothly passes into a board having a different form of profile.

The main purpose of the wheel disk is to ensure the proper landing of the tire and its efficient work During movement. That is why the basic requirements for the disk are strength and rigidity. Also, the disk should have a relatively small mass and geometric parameters specified by the manufacturer. This is due to the fact that the wheels, as an unsophisticated mass, affect the dynamics of the car movement and its handling.

Types of wheeled

Types of wheeled

Types of wheeled Depending on the material of manufacturing and production technology, there is the following classification of wheels:

- stamped;

- cast;

- forged;

- composite.

Stamped or steel discs

They are considered the most simple and affordable. Structurally, they are welded with each other steel stamped parts.

Pros of this type:

- Acceptable price.

- Relatively high strength.

- The possibility of recovery even in case of a strong impact.

By minuses include:

- Unassuming design.

- Large mass.

- Low resistance to corrosion.

Alloy wheels

Alloy wheels (sometimes they are still called alloy) are made of aluminum or magnesium alloys. These discs have high strength and good. In addition, they differ beautiful external species. If in steel disk The disc itself is connected to the rim of welding, the alloy disk is a single product.

Cast disc on car

Cast disc on car The total advantages of alloy discs include:

- High precision manufacture.

- Various disk design options.

- Ease.

- Well, heat from the brake mechanisms is well.

Among the disadvantages of the cast disc can be noted its relative fragility. Such a disc has a grain internal structure of a metal that is badly resisting shocks. In the process of movement in irregularities, microcracks accumulate, as a result of which the disk is sooner or late can split. As an option, an increase in the thickness of the walls, which will lead to an increase in weight. It is also expensive and difficult to restore it.

In addition, this type of disk needs to protect the surface. Otherwise, casting will lose its freight look.

Wrought disks

Composite disks

Composite disks Further improvement of cast discs led to the appearance of forged disks or "forging." This type of stamping of aluminum alloys with the addition of magnesium and titanium and subsequent mechanical processing is performed. This provides a fibrous disk structure consisting of several layers. As a result, the product is characterized by high strength, low mass and resistance to shock loads.

The main minus "forging" is a high price.

Combined or composite disks

This type of discs combines the strength of "forging" and the design of "casting". The product is based on cast design with forged rims screwed bolts. The high cost of the disks overlaps many of their advantages.

Wheel disk parameters

Basic wheelcase parameters

Basic wheelcase parameters Wheel disks are characterized by the following parameters:

- rim width (distance between shelves);

- disk diameter;

- departure disk;

- the number of holes for fastening and the diameter of their location;

- the diameter of the central opening of the disk.

Width rim

The rim width must be 25-30% less than the width of the tire profile. Operation too broad (equal as too narrow) disks are undesirable. Due to the violation of the project profile, the tire is worsening the driving characteristics of the car.

The permissible deviation from the norm in the distance between the shelves is 0.5-1.0 inches for disks with a diameter of up to 14 inches and 1-1.5 inches - for disks with a diameter of more than 15 inches.

Diameter disk

Mounting disk diameter or planting rim wheel Disc Under the tire is measured by the level of shelves. There is a dimension range of disks with a diameter of 10 to 22 inches. The average indicators obtained the greatest distribution: from 13 to 16 inches.

Departure disk

The departure of the disk or its protrusion is the distance from the vertical axis of the symmetry of the disk to the bustal plane of the contact with the wheel hub.

The disk departure can be zero and positive when the disk hub protrudes out with respect to the axis of the disk symmetry. In the case where the hub is recessed relative to the middle of the disk, the departure will be negative.

The magnitude of the departure is expressed in millimeters and is indicated as ET. With a positive departure, the maximum value of ET is 30 mm. In the case of a negative departure, the critical value of the ET is also 30 mm, but with a negative sign.

This indicator must comply with the instructions of the car manufacturer. Otherwise, the car handling may change for the worse, and the resource of suspension and transmission elements (drive shafts, hubs, etc.) can also be reduced. This happens because the change in departure entails the change in the shoulder of the forces and moments attached to the wheel while driving. Also, depending on the departure, it may vary that negatively affects braking.

The layout diameter of the holes for fastening and their number

This indicator has a PCD designation. The first digit in the indicator indicates the diameter of the location of the holes, and the second is on their number.

Standard diameter values \u200b\u200bare considered from 98 to 140 mm, and the number of holes ranges from 4 to 6.

It is very difficult to determine the correspondence of the size of the disk and the hub. And the installation of the disk of the incorrect diameter can lead to the dispensing of the wheel, which will lead to its "bias".

Diameter of the central opening of the disk

The diameter of the central or board opening of the disc varies from 50 to 70 mm. The accuracy of the selection of the disk in accordance with the hub is very important. But this refers to the regular wheels of the car. Spare parts manufacturers often produce a hole slightly larger diameter, and a set of transition rings offered with a disc. In this case, the wheels will be centered by PCD.

Decoding disc marking

Marking discs

Marking discs Marking discs characterizes its dimension. It is applied, as a rule, on the inside of the hub of the cast disk. Imagine the designation of each of the indicators as follows: 5.0 × 16 "4 × 113 ET28 D58.4where

- 5.0 - the width of the disk in inches;

- 16 "- disk diameter in inches;

- 4 × 113 - the number of fastening holes and their diameter;

- ET28 - departure disk;

- d58.4 - Diameter of the central hole.

Conclusion

When choosing wheel drives, it is necessary to take into account both their technical characteristics (such as: diameter, width of the disk and other indicators) and the quality and origin of the disks themselves. Otherwise, the purchase depends on the preferences of the motorist and its readiness, acquiring discs, part with one value or another.

You can get acquainted with the decoding of the designation of the tires (tires) you can.

The number and landing diameter of the holes for fastening the wheelbarrow.

6.5J × 15 H2 5/12 ET39 D57.1- "Five holes on a diameter of 112 mm"

| The first digit is the number of bolts (or nuts) \u003d the number of mounting holes in the disk for bolts or nuts (the most common wheels are found with the number of mounting holes from 4 to 6, less often there are 3, 8 or 10. In our case 5. The second digit is the diameter in mm, on which the centers of these holes are located, which is called PCD \u003d Pitch Circle Diameter And in our case, it is 112 mm. In the tire industry for chic is often called the term "PCD" both of these parameters immediately, and indicating the PCD disk written 5/12. Wheel mounting holes are located on various diameters with a rigid positional tolerance in relation to the central opening. There is a limited number of such diameters (examples - 98, 100, 112, 114.3, 120, 130, 139.7 and some others, they are used by automakers or by tradition, or as the most suitable for certain types of cars - so, size 139, 7 is typical for pickups and SUVs). Occasionally, wheels with two "sets" of 4 or 5 mounting holes located on two different diameters are occurring.

|

|||||||||

The central hole of the disk, the diameter of the hub.

6.5J × 15 H2 5/12 ET39 D57.1- "Hub hole 57.1 mm"

d 57.1 - the diameter of the centering opening on the disk. Must accurately correspond to the diameter of the planting cylinder on the hub. Often the same wheel (wheel drive) is offered for cars different firmsTherefore, the central hole in the wheel disk should be different. Since in addition to the centering function, the landing cylinder has another, no less important - it partially assumes the load, which falls on the mounting bolts (studs). Therefore, if the centering opening of the disk you like is more landing hub cylinder - you will have to use special centering rings that can be bought in tire centers, or order somewhere. The external and internal dimensions of the centering ring must be accurately responding, respectively, the diameters of the hub cylinder and the centering opening of the disk. |

Width wheel rim.

The disk wheel consists of two main parts: rim and disk actually. The disc is the central part of the wheel, with which the wheel is attached to the car hub with bolts or nuts. The rim is the cylindrical part of the wheel of a special profile, which is located perpendicular to the disk and serves to mount the rubber tire on it.

6.5 J × 15 H2 5/12 ET39 D57.1- "Planting width of a disk (rim) 6.5 inches"

6.5 - landing (! Not overall!) Width of the wheel rim in inches (sometimes the value of the disk width in the marking is indicated in the form of fractions 6 1/2). The width is measured not by the external parties of the disk, from the edge and to the edge, and by the so-called "disk shelf" to which the sidewalls of the tires fall. 6.5 - landing (! Not overall!) Width of the wheel rim in inches (sometimes the value of the disk width in the marking is indicated in the form of fractions 6 1/2). The width is measured not by the external parties of the disk, from the edge and to the edge, and by the so-called "disk shelf" to which the sidewalls of the tires fall. The width of the disk and the tires must strictly match each other so that the tires, after installing on the discs, had the optimal form specified by the manufacturer. Dimensions: Always given in inches (1 inch \u003d 25.4 mm), except for the designs of the company "Michelin", which will give dimensions in millimeters. ATTENTION: The width and diameter are selected according to the size of the rubber bus. To determine the overall width of the wheel rim, it is necessary to add to the value of the rim width on the marking of another 26 mm. That is, the thickness of the outer and the inner sideboard. The overall rim width must be at 12 (plus-minus 4) mm less than the width of the rubber tire profile |

Wheel Diameter.

6.5J × 15 H2 5/12 ET39 D57.1- "Diameter (size) of a wheel disk 15 inches"

15 - landing (! Not overall!) The diameter of the wheel rim in inches, which is obliged to fit the tire's planting diameter. On passenger cars, wheels are applied with a diameter of 12 to 32 inches, the most common diameters of 14-16 inches. 1 inch \u003d 25.4 mm.

Wheel departure. Takeaway wheel.

6.5J × 15 H2 5/12 ET39 D57.1 - "Positive wheel departure 39 mm" |

|

ET \u003d 39 - departure or removal of the disk in mm (this parameter can also be marked offset and deport). Usually, no problem can be less than standard by 10 mm and, usually depends on the width width. The smaller the magnitude of the departure, the wider the wheelbase.

The departure of the disk is the distance between the wheelplate of the wheel disk (the plane of which is pressed the disk to the hub) and the middle of the width of the disk (imaginary plane passing in the middle of the rim). To determine the magnitude of the wheel departure, you need to measure the size "in" from the inside of the wheel. Split the size "x" in half. Subtract out of size "in" size x / 2. If the difference is positive, then the departure is positive, if negative, then departure "negative". Or, in other words: Departure "Positive" If the bustal plane does not switch for the imaginary plane. Departure "Negative" If the bustal plane passes through the imaginary plane. |

|

|

|||

Color rim, onboard cuts.

6.5J × 15 H2 5/12 ET39 D57.1 - "Type j" rim rim

J (jj, jk, k, b, p, d ...) This letter is encrypted technical information about the rim collar (design, shape, height). The most common types of discs today are J (mainly for monolavariferous cars), and JJ (usually for a full drive). Color rims are influenced by the installation of rubber compensating for weights, as well as resistance to the offset of the tire on the disk in extreme conditions. Obviously, despite the external interchangeability, for example, disks J and JJ, it is better to still choose the parameter recommended by the car manufacturer.Shelves and hamps rim shelves.

6.5J × 15 H2 5/12 ET39 D57.1 - "Shelves Trucks and Hamps type H2"

H (H2, FH, AH, CH ...) - Information about these letters encrypted constructive features Shelves of the rim of the disk and protrusions (Hampov) on them. Hampa (Hump) are designed for tubeless tires and provide proper installation Tires to disk. Some tires require special disk parameters in this matter, this moment must be clarified when buying tires. In general, it is not necessary to deeply delve into the essence of these designations.

Other possible designations.

The disk may also indicate:

- Manufacture date. Usually year and week. For example: 0504 means that the disk is released at 5 week 2004.

- SAE, ISO, TUV, PCT ... - Stamp controlling organ. Marking indicates actions of wheels by international rules or standards.

- Max Load 2000lb. - Very often occurs the designation of the maximum load on the wheel (denotes in - kilograms or pounds). Here is the maximum load of 2000 pounds (908 kg).

- Max PSI 50 Cold - Recognizes that in the bus should not exceed 50 pounds per square inch (3.5kgs / sq. CM), Word Cold (Cold) means that the pressure should be measured in a cold tire.

- Other

Fastening the wheel. The order of tightening bolts (nuts). 110 Nm

11 kg * m

7/16 inches

80 nm

8 kg * m

1/2 inches

90 nm

9 kg * m

Rubber wheel for a passenger car. Compliance with rubber tires or disks for one car model.

To the selection of car drives should be taken with great care and attentiveness! Each disk has several parameters for installation on a car, each of which must be considered when choosing. Some parameters are unchanged, and some can be corrected in a small range. This article will tell about all the intricacies of the selection of cast and forged discs.

Disc parameters

Size A. (disk diameter in inches) - the landing diameter - the diameter of the ring part of the rim on which the tire is based on.

Size B. (The width of the disk in inches) - the landing width of the rim - the distance between the inner surfaces of the onboard creek wheels. Specifies the possible width of the tire installed profile. It is allowed to deviate the landing width by 0.5-1 inch, however, for low-profile tires it must be minimal.

HUMP (Hamp) (width in inches) - a ring protrusion, serves for additional fixation when mounting beadless rubber sides.

ET. (departure in mm) - departure (removal) disk, i.e. The parameter defining how deep the wheel is recessed into the car's arch. Departure is the distance from the disc plane adjacent to the car hub, to the plane passing through the axial middle of the rim width of the disk. For each car, the manufacturer provides a list of permissible options for setting the wheels. This parameter can be changed by +/- 5 mm without harm to the car suspension. With the greatest retreat, the option is required both on the front and on the back axis of the car, since it is possible that the disk will be restarted into the elements of the suspension, fenders or parts of the car braking system. In addition, the installation of wheels with departure, significantly less provided, leads to a significant reduction in the stability of the car in turns, increased sensitivity of the steering to road irregularities and non-uniformity of brake efforts.

PCD. - the number of mounting holes and the diameter of the circle of the centers of these holes. This value must match the standard, otherwise it is impossible to achieve reliable fixation of the wheel on the car hub. Deviation even by 1-2 mm can lead to a disk of the wheels and fastening elements.

Dia (CSO in mm) - the diameter of the central opening of the disk. It must correspond to the diameter of the centering protrusion on the car hub. It is allowed to deviate its magnitude in the most side. In this case, transitional centering rings are used to install the wheel.

Disk parameters can be referred to as follows, for example:

6x15 ET45 5X100 D57.1

6 - Width of the disk in inches;

15 - disk diameter in inches

Et45 - departure (removal) disk (in mm);

5x100 - PCD., the number of mounting holes on a certain diameter of the location. It is necessary to take into account that for each car it (diameter) should not be changed under any circumstances;

D57.1 - Dia (TSO)

or like this:

6.5 J 15 H2 5x114.3 ET45 D54.1

6.5 - Width of the disk in inches;

15 - disk diameter in inches;

5x114.3 - PCD., The number of mounting holes on a certain layout diameter.;

Et45- departure (removal) disk (in mm);

D54.1 - Dia (TSO) The diameter of the central opening of the disk, is measured in mm;

J. and H2. - Symbols you need more specialists. IN J. Encrypted information about the design of onboard rim rim (maybe jj, jk, k or l). BUT H2. - this is the code of the design of the champs, ring protrusions on the landing shelves of rims serving to reliably hold the tubeless tire on the disk, (variations a lot: h, fh, ah, etc.);

Cellular - what it is on the iPad and what's the difference

Cellular - what it is on the iPad and what's the difference Go to digital television: What to do and how to prepare?

Go to digital television: What to do and how to prepare? Social polls work on the Internet

Social polls work on the Internet Savin recorded a video message to the Tyuments

Savin recorded a video message to the Tyuments Menu of Soviet tables What was the name of Thursday in Soviet canteens

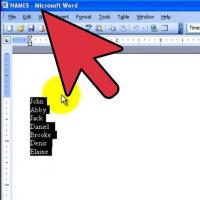

Menu of Soviet tables What was the name of Thursday in Soviet canteens How to make in the "Word" list alphabetically: useful tips

How to make in the "Word" list alphabetically: useful tips How to see classmates who retired from friends?

How to see classmates who retired from friends?