Laptop battery charging board repair. Restoring a laptop battery yourself. Awakening sleeping lithium-ion batteries

Before you attempt to restore the work of a portable computer battery, you should define the type of device. Their three: nickel-metal hydride, lithium-ion, lithium-polymeric. Most often in laptops are used by the last two types. Their main minus is the briefness - only about 300 cycles of work. However, it is possible to reanimate the device and personally at home ...

First you need to disassemble the battery. Make it is not so simple - the battery parts are fastened reliably. To work, you will need a sharp thin knife or scalpel. Pressing on the seam, carefully disassemble the device on the part. Try not to damage the "inside." Next, make sure that the battery is completely discharged. To determine this, you need to resort to the help of automotive light bulbs and multimeters. Connect them to the battery. You can proceed to repair work if light sources are burning. It is worth noting that the overall voltage at the multimeter should be equal to the number of elements that are multiplied by 3.7 or more. In case the voltage on the measuring device is less than necessary, you will have to check each battery element and as needed to replace damaged or faulty parts.

Putting the battery to a place in a laptop, fully charge it. So that your battery serve you as long as possible, adhere to the rules of operation.

If we did not drop the laptops, they did not poured their coffee (tea, cola, beer - needed to choose) and there would be no time from time to time, they would work almost a dozen years. However, the rechargeable battery of the laptop by definition resource is limited, and you are still lucky if the battery lasts longer than 5 years.

Gradually, its capacity decreases, which means that the operation time is reduced from one charging, but it happens that the container drops sharply. The case can reach the battery overheating and even an explosion.

If you notice that the battery on a laptop begins to refuse, do not rush to order a new one in China or buy the same with us, but already twice as much. The people on the forum speaks to Chinese batteries extremely negative: it also has a capacity below, and the resource is at times less. Somehow I did not want to wait a month to get a battery with a resource of half a year - a year.

But there is another option - the independent repair of laptop batteries with the replacement of elements that have lost resource.

Where to begin? With diagnostics!

First of all, you need to find out how shrunk the time of the laptop after charging the battery, how adequitably the level of its charge is estimated. There are special programs for testing the battery, including the free Batterymon program.

The program includes charts and discharge.

And in the 'Info-\u003e BatteryIinformation ...' menu, it contains very useful information:

Chemistry - type of battery, for example, Lithium Ion (lithium-ion);

Design Capacity is its design capacity, that is, the maximum container that he possessed immediately after the manufacture;

Full Charge Capacity - the maximum value that the battery charge may be;

CURRENT CAPACITY - the current value of its charge;

Voltage - the current voltage value on the battery;

CHARGE RATE - battery charge / discharge rate.

But we are primarily interested in the remaining battery resource, which can be defined if divided by 'Full Charge Capacity' on 'Design Capacity'. The lower the remaining resource, the higher the battery wear.

How to replace the Battery Elements of the Toshiba Satellite T230-12T Laptop Battery

TOSHIBA laptop was operated very intensively and almost all the time was connected to the network. After 5 years, the time of its autonomous work decreased by about 30%, besides, the battery began to overheat, so during charging the laptop became uncomfortable on his knees. If the charging was not turned off when the battery reached a complete charge, the laptop overheated and disconnected himself.

Disassemble the laptop battery

The laptop battery makes sense to repair with your own hands, only if you are sure about the serviceability of the controller card, if the controller is faulty or blocked, it will be cheaper to contact a specialized workshop.

The sequence of action is:

Remove the battery from the laptop;

We divide the plastic case into two parts and carefully remove the battery of the elements with the controller board; And since it can be quite difficult, can help the following:

so that the halves of the housing are easier to diverge, the battery should be twisted in their hands and at the same time to move it diagonally in different directions so that the halves of the housing are revealed;

You need to try to find a gap between halves and put a plastic card into it, push the slot and continue to move the circuit card;

At the corners of the body for separation, you can use a flat screwdriver, but act very carefully so that it does not jump and damaged the controller board, the battery element or your hand.

Next, define the diagram of connecting the battery elements and connect to the controller board. The most convenient to make the collection photo, draw the electrical circuit of the connection and put it in it the polarity of the connection of the elements.

At the TOSHIBA battery, the combination circuit of the elements is indicated as 2p3s, that is, two elements are connected in parallel, and three of these blocks are connected in series.

The scheme must be confirmed by a voltmeter:

First, we define a common point that on the controller board is usually designated as 0V or GND,

We measure the remaining stresses at the assembly point points to the controller board (at all points relative to zero, the voltage should be positive, otherwise the general wire is most likely chosen),

We are reading on the scheme,

We find a point with the lowest potential,

Check the sequential increase in the voltage at each element block connected sequentially (the increase should have a positive value)

This is how the thermal sensors are fixed on the elements.

Attention! Note that:

While the controller board is connected to the items, you can not charge or discharge using external sources, you can only perform stress measurements, otherwise the controller can be blocked or generally approved;

To avoid blocking the controller, it is necessary to disconnect it from the element assembly in a strictly defined sequence: first digging the wire (or the bus) with the highest voltage - it will be a positive contact of the battery member, which is from the very edge from its zero, after that - the wire from the remaining, which is the biggest tension, and so repeat to the last wire.

After that, the controller and the scheme is better to remove away, so as not to lose and not damage anything.

Voltage range

Much depends on the type of chemistry of elements. In most cases, these are Li-Ion batteries with a voltage of 3.6 V; They can be charged to a voltage of 4.2 V and discharge up to 3.0 V. It is important to know the range of battery life so that it does not work out that new elements are designed for narrower than the initial, range. If the voltage is above the tolerance, the elements will overheat and even explode; If the voltage output will be below the permissible, it will lead to a sharp loss of the container. Alternatively, it is possible to use elements with a wider voltage range, but they may be too expensive.

Charge and discharge currents

With charge / discharge currents, there are usually no problems, the laptops do not use high-current batteries, but still it is recommended to clarify the current ability.

Battery capacity

It is desirable that the capacity of the batteries is comparable to the capacity of the original elements. If the container is underestimated, the battery life of the laptop will be reduced; If it is overestimated, then without flashing the controller, the operation time will increase slightly.

Thus, when replacing elements with 2900mach on 3350mach, a 15.5% increase in capacity was expected. And the battery controller of the laptop was programmed to the elements per 2800mach, and they were replaced with elements with a capacity of 3000mach.

For example: Assembly of six lithium batteries with a voltage of 3.6 V. How to translate the capacity from watt clocks for the battery to amp-clock for an element? We divide the first to 6 (the number of batteries), and then another 3.6 V (voltage on the element).

If you wish to save if the battery life does not matter, it is possible to put items to a lower container or reduce the number of batteries included in the parallel (for example, instead of put 1). But it is previously necessary to clarify the current load of the batteries, since if the batteries are calculated for a lower capacity, then they are usually a smaller current.

Dimensions

Be sure to consider the dimensions of the batteries. The most common standard size that is used in removable laptop batteries is a cylindrical 18650, where the first two digits are denoted by the diameter of the battery (18 mm), and 65 mm is its length. If the length is due to the design features of the electrodes, etc. will be more, then such batteries may simply not fit into the old case.

Laptop battery recovery

Restoration of the disassembled battery is appropriate only if:

When disassembling the old rechargeable battery, the controller fee was not damaged;

No short circuit happened;

The assembly of the elements was disconnected correctly (from the maximum plus to minus);

The battery controller was not blocked and did not fail.

Acquisition of a new controller or programmer search and program to unlock the controller is impractical if it comes to unit repair of the battery.

First of all, it is necessary to establish the brand of old elements and their characteristics with the type of chemistry, voltage, charge current and discharge current, with a capacity (this data is on the Internet). This is necessary to search for new workable elements.

Where to take items

It is possible to recycle good old elements; You can buy them in your city or order in foreign stores or on eBay or Aliexpress.

How to solder batteries li-ion

At the production of the assembly of the battery from the elements is carried out using the contact welding. Many believe that if the battery is soldered, it will fail or serves a little. But if soldered correctly and exclude operation in extreme conditions, it will be possible to do without contact welding apparatus.

For proper soldering, you will need:

Soldering iron with a wide stare with a capacity of at least 40 W (better with temperature stabilization);

soldering acid and brush (can be replaced with a cotton wand);

solder tin type POS-61;

paper essay or feet;

Fit clamp to fix batteries.

High-quality soldering will succeed only if the soldered surfaces are correct. When soldering batteries, the most important thing is to prevent overheating. Therefore, it is necessary:

So that the room was well ventilated;

A temperature of 350 ° C should be exhibited on the soldering iron;

electrodes must be cleaned;

The element must be securely fixed.

Procedure Next:

1) With the help of a bruster (or cotton sticks), the electrode is a little acid.

2) To dial more solder on the sting of the soldering iron.

3) Moving the sting vigorously, to grasp the solder into the electrode.

Important:

The battery can not be afraid longer than 2 seconds; If they did not have time for 2 seconds, then postpone the element and try again, only when it cools;

When soldering, it is impossible to inhale the evaporation of acid, they are very harmful to health;

After you enter the battery, be sure to remove the residues of the soldering acid using a roller moistened in alcohol or at least in vodka;

safer to solder battery with already welded petals; So, at the battery 18650 with petals, the very edges of the petal should be faced so that the element itself does not heat up.

This is what the new battery with a petal of mobile charging, welded with contact welding.

After completing the logging of all items, it should be checked for equal tension on all of them. If there are differences in more than several hundred volts, the voltage must be aligned using a special charger or connecting the batteries in parallel.

Be careful: if the elements connected in parallel, the different degree of charge and, accordingly, different voltages, can proceed huge currents, as they limit only the extremely small inner resistance of the batteries and the resistance of the circuit wires.

To limit the current to break the battery circuit, it is necessary to turn on the resistance resistor not lower than DU / IMAX (voltage difference on battery elements, divided by the maximum allowable charge / discharge current).

The connection of batteries and the resistor is carried out according to the following scheme; Then you should wait until the value of the voltage on the resistor is less than the volt cell.

Balanced the voltage on all elements, go to the assembly of them into the battery. The easiest option is to connect new elements with the help of old connecting tires, if they were damaged during disassembly, the copper foil is required with a thickness of 100-200 μm.

When assembling elements in the battery, the initial battery circuit should be followed; The location of the elements is desirable to leave the same as in the original battery.

Soldering batteries

When assembling the battery from six elements, it is advisable to combine all the elements of pairs: the disadvantages of the two elements together and the pros also, after which the three pairs are consistently.

After assembling the elements, the controller is connected to it, and in the reverse order, starting from the wires with the lowest potential and then upwards: first 0 V and 3.6 V, then 7.2 V and at the very end of 10.8 V.

Now it remains only to carefully assemble the battery and check it (the battery case is not worth it). Connecting the battery to the laptop, press the power button. If the laptop did not turn on, this means that when the old battery build was disabled, the controller transition occurred to the transport mode, and it turned off the battery. If you connect now to a laptop network nutrition, it will "start" and sees the restored battery. Repair ended successfully.

There are often cases when the laptop battery ceases to keep the container. The battery autonomous time is reduced at times, and accordingly, the laptop loses its advantages over the PC. The reason for the defect is to use a laptop with a constant connection to the AC network.

Causes of the inoperability of the battery

Given that the battery elements have a "memory effect" and a variety of properties, the battery charges unevenly. Some elements have already achieved complete charge, others did not receive 50% of the norm. Voltage on the elements that are already charged, grows. The controller believes that the process is complete, and reduces the tank half. Over time, the controller enhances this phenomenon, and growth is observed in geometric progression. The laptop battery can be fully inoperable.

You can repair the battery on your own, but first it is necessary to find out what kind of battery in the laptop. As a rule, there are:

- Gelian

- Nickel-metal hydride

- Lithium-ionic (most popular).

Accumulator calibration

Before restoring the battery, you can calibrate it.

Option testing of a laptop charging, can be seen on the video:

Calibration will show the level of discharge and charge of the battery capacity, will allow you to independently adjust the controller. For battery using lithium, calibration is an effective method of getting rid of the "memory effect" of the controller. If the battery that has a laptop can be calibrated through the BIOS program, you need to try.

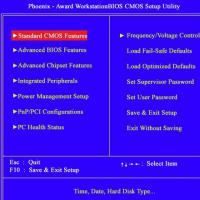

The Phoenix BIOS program works as follows:

- You can press F2 or DELETE to enter the BIOS (it all depends on the laptop model)

- Next to BIOS, you should select Boot -\u003e SmartCalibration and click "Yes" in response to the program proposal to calibrate the battery

- The program will show a charging percentage.

To calibrate through the BIOS, you must completely discharge the laptop battery. The program should work when the power supply is disconnected, exclusively when charging the laptop from the battery. Through the BIOS, it is recommended to drive a "training cycle" monthly. It will eliminate the device from the "memory effect" and will retain the autonomy that the laptop has. If it is impossible to make calibration via BIOS, there are third-party utilities that allow you to examine the charging of the laptop on Windows.

Calibration through Batterycare.

In particular, you can use Batterycare, which works on various versions of Windows. The principle of calibration using this software product is similar to what is happening in the BIOS. Of course, it is impossible to bypass the physics of the battery, but you can optimize charging consumption.

The Batterycare interface is shown in the photo:

- 1 is the controller load indicator

- 2- Changing the charge level

- 3- Actual charge value

The approximate time is also shown, how much the laptop will work at the designated capacity level. The application also performs optimizing Windows processes and allows you to change the power scheme.

How to repair a laptop with your own hands

If the battery is already spoiled in the process of improper operation of the laptop, you can try to restore the container with your own hands.

To repair the device, you will need a multimeter, car light bulbs, superchalters, a dump knife and a soldering iron. Next you need to do the following:

- Disassemble the laptop and pull out the battery. The element must be divided into two parts by seam.

- Check whether it is discharged (on each site of the device you need to lower the voltage up to 3.2 V). It is necessary that the controller can charge the laptop from scratch.

- If the charge is zero, you need to connect the power supply through the 5 W lamp (the circuit is sequential) and wait, when the voltage is 3.4 V.

- At the end of the repair, you can start assembling the battery with your own hands. Cyan-acrylate glue is used for gluing.

How to repair a laptop, shown on the video:

However, a little repaired the battery, you need to properly exploit it in the future, to extend its term and not "mislead" the controller.

The battery capacity and the time of operation from one charging are one of the important parameters of the laptop. They influence the final price, the choice of the buyer. Whatever qualitative to these characteristics, any battery is designed for 300-400 charge-discharge cycles. It is important to try to discharge the battery before the next recharging. To shorten the period of normal operation of the battery (AKB), overheating, supercooling, leaving the laptop turned on until the battery is completely discharged. After deterioration of the quality of charging, the battery should be restored.

What is a battery on a laptop

The rechargeable battery performs the function of the power supply of all the functional elements of the laptop. To increase the duration of work in the absence of electricity, it is necessary to minimize the number of working components, turn off bluetooth, Wi-Fi, close unnecessary applications. Akb may have an elongated rectangular shape or square. There is a battery on the back of the laptop, has a spring latch for easy installation and removal. This element is sensitive to overheating, so do not store a laptop near the heating devices.

Laptop battery recovery

If the computer's work time after charging the battery is rapidly decreasing or the computer does not turn on, this suggests that the battery is required and the laptop battery restore is required. Self-restoration of the battery is a process that requires tools, such work skills. In the absence of both these components, the best choice will be the acquisition of a new battery or an appeal to a service company that repair the laptop batteries. Restoration is possible with full disassembly / replacement of rechargeable cans to new ones.

Instruments

If you decide to repair the battery yourself, you will need the following tools:

- multimeter - the arrow or electronic device for measuring DC voltage is suitable;

- knife or thin screwdriver - for disassembling or opening unintellular models of AKB;

- soldering iron, solder, flux - for disassembly and connecting together new cans;

- multifunctional IMAX B6 type charger required to check the level of charge, firmware, balancing batteries;

- glue, tape - need when assembling the battery.

Laptop battery recovery program

Decide the need to restore the laptop battery will help software products that, when installing on a computer, begins to monitor charging-discharge cycles, are able to determine the quality of the battery, the degree of their wear. The most popular utilities for these purposes are:

- Batterymon;

- Batterycare.

BatteryMon is a free Windows program for monitoring the laptop batteries, determines the performance of the batteries, a tendency to breakage. The program will provide the user with the following information:

- akb charging schedule in real time;

- battery charge log file for analysis;

- information on the state of each battery;

- the results of the BurninTest-produced test - battery performance testing under load.

Batterycare - utility that will provide the results of monitoring:

- statistics of charge-discharge cycles;

- calculate the percentage of wear;

- acB capacitance;

- voltage and battery discharge / discharge power;

- current processor temperature, hard disk;

- message about the critical level of charge;

- information about the need to calibrate batteries.

Battery repair laptop do it yourself

If you decide to balance or repair the battery of your laptop, you will need to perform:

- Disassembly of the battery - some models provide for a screwdriver disassembly, in most cases, the battery has a glued structure, for the disassembly of which the knife or acute screwdriver will need.

- Balancing - is performed when the residual voltage is skewed or its magnitude with the full charge of individual cans.

- The replacement of batteries - can be made partially or all batteries. When buying new elements, pay attention to the voltage, container and the date of their release.

- Assembly - it will be easier if there are screws, otherwise it will take instant glue for plastics.

Laptop battery disassembly

The simplest way there will be a disassembly of a repeated battery. To do this, you will need a cruciform screwdriver of a small size. The glued design is more difficult to disassemble - for this you will need a sharp knife, which is needed under the bright light, it is necessary to find a glued place, cut through the gap, remove the battery cover. This should be done carefully, so as not to damage the banks, the thermal sensor or the controller board, on which the connector is often installed. Standard laptop battery set consists of 8 cans. For balancing, you should not hurry and disassemble banks - their recharging can be produced separately.

Replacing batteries

SAMSUNG and LENOVO laptops are used in the Notebooks of the Popular Marks of Samsung and Lenovo, the cylindrical lithium batteries are 18650 with a rated voltage of 3.7 volts, a capacity of 2200 mAh connected by a sequential scheme. After 1-2 years of operation, the properties of battery cans begin to differ from the nominal values. The maximum charge of the batteries (SBS) changes, the capacity, the self-discharge appears. The multimeter will be able to identify those who need to replace the banks - they will be:

- minimal residual voltage (less than 3.6 V) in the discharged state;

- hurried voltage in charged state.

If you purchase the necessary batteries, it is possible to replace the battery in the laptop battery. You can reanimate the battery with good banks if you push each of them using a charger or car battery. It is possible to fix the battery without buying new cans. Connecting the minus side of the bank to the battery plus, it is necessary for 1-3 seconds to close it plus on minus auto accumulator, after which the voltage is measured on the bank. In this way, it is advisable to check all the banks and to bring to the nominal one for each potential.

Battery assembly

The factory connection of the banks of the battery is made by thin busbars and contact point welding, replaced at home can solder. For disassembly, heal the soldering iron of the welding site and disconnect the cans. When repacking, the heated busbar is processed by flux to remove the oxide film, then solder or tin with rosin on the contact site on the bank and busbar. Connect them and warm the scene of the joint. After moltening the solder on both docking elements, the soldering iron is cleaned, but keep the joint under pressure until solder hardening.

After connecting all the cans, check the battery charging, making flashing, connecting the IMAX B6 MFP charger wires to the corresponding contact sites on the controller card. After charging, it is necessary to check the charging of the entire battery and individual cans with the help of the multimeter. At the normal charge, the battery can be collected. Insert banks into the case, apply instant glue, press the lid. Hold the glued parts under the press to the complete drying of the glue. Then install the repaired and restored battery in its place in the laptop.

Our regiment arrived - a very interesting copy appeared in my collection - Micron Transport XKE 1995, a very charismatic and interesting laptop must be said, but he had a problem - an absolutely dead battery. All my attempts to "dig" were not crowned with success, and it was decided to disassemble it and try to repair. It was said - done, the battery is disassembled, and before my gaze appeared depressing picture:

What was next? (Caution - traffic)

Banks flowed, stress measurements showed that two thirds of the cans are dead.

In the course of the matter, it was necessary to solve the puzzle, and make a fundamental scheme of the connection of the battery cans (I give a photo of a special draft, which always lies under the keyboard for urgent records):

The CHEMA was simplified and it became clear that the battery consists of 3 sequentially connected blocks of 4 elements each:

But where ours did not disappear! My view fell on the battery from the ThinkPad T60 with a dead controller and quite alive elements, the opening showed that there are the same 3 blocks of cans, but only 3 elements each, the voltage was similar, the capacity of the IBM batch was more, well - worse will not be. The elements were disassembled and re-soldered in the form that would fit into the housing from the battery.

Attention! Working with banks should be extremely gently so as not to arrange a KZ and not overlay the jar.

Test testing has shown that the laptop from this design starts. The joy was not the limit, but it was here that the first trouble was waiting for me, the banks from Thinkpad were a little thicker and longer than their relatives, therefore it was necessary to recycle the location of the elements in the housing and handle the body itself, and with the grief in half, banks rose to their place:

Everything was neatly snaps, checking the battery showed that banks work.

But when it was decided to pack the battery back, the problem of the dimensions of the cans again surfaced - the lid closed only under load, and therefore such a cocoon was made to gluing the superclay, and left for several hours (perhaps I will give up a story about watch dats around the battery with a file, matyuki and Colelet. This is important that the lid closed):

Next, the seams were cleaned with a skin, and in the end I received a monolithic design with very quite good for the first coma pancake seams of gluing:

The battery stood in his place as a free, trial launch was successful. Practice has shown that the lifetime from the restored battery is about 4 hours (I will test in more detail when the laptop is reviewed next time)

By the way, banks under their voltage, container, size and color can also be bought and new. The price will be released anyway cheaper than a new battery.

And I repeat once again - with these works, caution and TB must be taken, and also carefully examine the parameters of the cans and the compound scheme, in order not to accumulate and not burn the controller.

And at the end of a particular thank you, thanks to which this beast now lives with me (I don't post the overall photo, in order to leave the material for the subsequent detailed and interesting review of this device).

Causes of why Flash Player does not work, and troubleshooting

Causes of why Flash Player does not work, and troubleshooting The laptop itself turns off, what to do?

The laptop itself turns off, what to do? HP Pavilion DV6: Characteristics and Reviews

HP Pavilion DV6: Characteristics and Reviews Format representation of a floating point numbers How negative numbers are stored in the computer's memory

Format representation of a floating point numbers How negative numbers are stored in the computer's memory Computer fries and does not turn on what to do?

Computer fries and does not turn on what to do? Why does not work mouse on a laptop or mouse?

Why does not work mouse on a laptop or mouse? How to increase or decrease the scale of the page (font) in classmates?

How to increase or decrease the scale of the page (font) in classmates?