Simple circuits for testing transistors. A universal device for testing radioelements from a pointer tester. Fast accurate transistor check

Transistors and electrolytic capacitors.

Probe for testing transistors, diodes - the first option

This scheme built on the basis of a symmetric multivibrator, but negative connections through capacitors C1 and C2 are removed from the emitters of transistors VT1 and VT4. At the moment when VT2 is locked, a positive potential through an open VT1 creates a weak resistance at the input and, thus, the load quality increases probe.

From the emitter VT1, a positive signal goes through C1 to the output. Across open transistor VT2 and diode VD1, capacitor C1 is discharged, and therefore this circuit has a small resistance.

The polarity of the output signal from the outputs of the multivibrator changes with a frequency of about 1 kHz and its amplitude is about 4 volts.

Pulses from one output of the multivibrator go to connector X3 of the probe (emitter of the transistor under test), from the other output to connector X2 of the probe (base) through resistance R5, and also to connector X1 of the probe (collector) through resistance R6, LEDs HL1, HL2 and speaker ... If the tested transistor is working properly, one of the LEDs will light up (for n-p-n - HL1, for p-n-p - HL2)

If at checks both LEDs are on - transistor broken, if none of them is lit, then most likely the tested transistor has an internal break. When checking the diodes for serviceability, it is connected to connectors X1 and X3. With a working diode, one of the LEDs will light up, depending on the polarity of the diode connection.

The probe also has an audible indication, which is very convenient when dialing the wiring circuits of the device being repaired.

The second version of the probe for testing transistors

This circuit is similar in functionality to the previous one, but the generator is not built on transistors, but on 3 NAND elements of the K555LA3 microcircuit.  The element DD1.4 is used as an output stage - an inverter. The frequency of the output pulses depends on the resistance R1 and capacitance C1. The probe can be used for. Its contacts are connected to connectors X1 and X3. Alternate blinking of the LEDs indicates a working electrolytic capacitor. The completion time of the LEDs is related to the capacitance value of the capacitor.

The element DD1.4 is used as an output stage - an inverter. The frequency of the output pulses depends on the resistance R1 and capacitance C1. The probe can be used for. Its contacts are connected to connectors X1 and X3. Alternate blinking of the LEDs indicates a working electrolytic capacitor. The completion time of the LEDs is related to the capacitance value of the capacitor.

There is probably no radio amateur who would not profess the cult of radio-technical laboratory equipment. First of all, these are attachments to them and probes, which are mostly made by ourselves. And since there are never too many measuring instruments and this is an axiom, I somehow assembled a transistor and diode tester, small in size and with a very simple circuit. For a long time already there is not a bad multimeter, but a home-made tester, in many cases, I continue to use as before.

Instrument diagram

Probe constructor consists of only 7 electronic components+ printed circuit board. It assembles quickly and starts working with absolutely no configuration.

The circuit is assembled on a microcircuit K155LN1 containing six inverters. correct connection one of the LEDs (HL1 at structure N-P-N and HL2 for P-N-P). If faulty:

- broken, both LEDs flash

- has an internal break, both do not ignite

The tested diodes are connected to the terminals "K" and "E". Depending on the polarity of the connection, HL1 or HL2 will light up.

There are not many components of the circuit, but it is better to make a printed circuit board, it is troublesome to solder the wires to the legs of the microcircuit directly.

And try not to forget to put a socket under the microcircuit.

You can use the probe without installing it in the case, but if you spend a little more time making it, you will have a full-fledged, mobile probe that you can already take with you (for example, to the radio market). The case in the photo is made of a plastic case of a square battery, which has already worked out. All that was done was to remove the old content and cut off the excess, drill holes for the LEDs and glue a strip with connectors for connecting the tested transistors. It will not be superfluous to "put on" the identification colors on the connectors. Power button required. The power supply is an AAA battery compartment screwed to the case with several screws.

Fastening screws, small size, easy to pass through the positive contacts and tighten with mandatory use nuts.

The tester is ready. The use of AAA batteries will be optimal, four pieces of 1.2 volts each will give the best version of the supplied voltage of 4.8 volts.

This device, the circuit of which is easy to assemble, will allow you to check transistors of any conductivity without desoldering them from the circuit. The diagram of the device, assembled on the basis of a multivibrator. As can be seen from the diagram, instead of load resistors, transistors with conductivity opposite to the main transistors are included in the collectors of the multivibrator transistors. Thus, the oscillator circuit is a combination of a multivibrator and a flip-flop.

Simple transistor tester circuit |

As you can see, the transistor tester circuit is nowhere easier. Almost any bipolar transistor has three terminals, emitter-base-collector. In order for it to work, a small current must be applied to the base, after which the semiconductor opens and can pass a much larger current through itself through the emitter and collector junctions.

A trigger is assembled on transistors T1 and T3, in addition, they are the active load of the multivibrator transistors. The rest of the circuit is the bias and indication circuits of the transistor under test. This circuit works in the range of supply voltages from 2 to 5 V, and its current consumption varies from 10 to 50 mA.

If you use a 5 V power supply, then to reduce the current consumption of the resistor R5, it is better to increase it to 300 ohms. The frequency of the multivibrator in this circuit is about 1.9 kHz. At this frequency, the LED looks like a continuous light.

This device for testing transistors is simply indispensable for service engineers, as it can significantly reduce the time for troubleshooting. If the tested bipolar transistor is functional, then one LED is on, depending on its conductivity. If both LEDs are on, then this is only due to an internal break. If none of them is lit, then there is a short circuit inside the transistor.

Picture given printed circuit board has dimensions of 60 by 30 mm.

Instead of the transistors included in the circuit, you can use the KT315B, KT361B transistors with a gain above 100.. Diodes are absolutely any, but silicon types KD102, KD103, KD521. LEDs are also any.

Appearance of the assembled transistor probe on a breadboard. It can be placed in a case from a burnt-out Chinese tester, I hope you will like this design for its convenience and functionality.

The circuitry for this probe is simple enough to repeat, but useful enough for rejecting bipolar transistors.

On the elements OR NOT D1.1 and D1.2, a generator is made that controls the operation of the transistor switch. The latter is designed to reverse the polarity of the supply voltage across the transistor under test. By increasing the resistance of the variable resistor, one of the LEDs is glowing.

The conductivity structure of the transistor is determined by the color of the LED. The scale of the variable resistor is calibrated using pre-selected transistors.

Good day everyone, I want to present here such a probe for transistors, which will show whether it is working or not, because it is more reliable than just ringing out its conclusions with an ohmmeter like diodes. The circuit itself is shown below.

Probe circuit

As we can see, this is an ordinary blocking generator. It starts easily - there are very few parts and it is difficult to confuse anything during assembly. What we need to assemble the circuit:

- Bread board

- Any color LED

- Momentary button

- 1K resistor

- Ferrite ring

- Varnished wire

- Socket for microcircuits

Parts for assembly

Let's think about where you can pick from. You can make such a breadboard yourself or buy, the easiest way is to assemble it with a canopy or on a cardboard. The LED can be picked out from a lighter or from a Chinese toy. The momentary button can be picked from the same Chinese toy, or from any burned-out household device with a similar control.

The resistor is not necessarily 1K - it can deviate from the specified value within 100R to 10K. The ferrite ring can be obtained from energy saving lamp, and not necessarily a ring - you can also use W ferrite transformers and ferrite rods, the number of turns is from 10 to 50 turns.

The wire is varnished, it is permissible to take almost any diameter from 0.5 to 0.9 mm, the number of turns is the same. The robots will learn the method of connecting the windings for the correct one during the tests - if it does not work, then simply swap the ends of the terminals. That's all, and now a short video of the work.

Video of the tester's work

13-07-2016

Andrey Baryshev, Vyborg

Pointer testers of type 4353, 43101 and others were widespread at one time. The devices had built-in protection and made it possible to measure various electrical parameters, however, they were cumbersome, and when measuring the capacitance of the capacitors, they were tied to the mains voltage. At the same time, the testers had good pointer measuring heads that can be used in designs with much smaller dimensions and greater capabilities. So, using this head, a small benchtop analogue measuring device was made with a minimum number of control elements. It allows to measure, with sufficient accuracy for a radio amateur, the capacitance of non-polar capacitors (5 pF - 10 μF), inductance of coils (from units of μH to 1 H), the capacity of electrolytic capacitors (1 μF - 10,000 μF) and their ESR, to have "at hand" fixed reference frequencies (10, 100, 1000 Hz, 10, 100, 1000 kHz) and, in addition, a built-in module can be added to it for operational verification of operability various transistors low and high power and determination of the pinout of unknown transistors. Moreover, you can check the parameters of most of the elements without unsoldering them from the circuit.

The modular design of the device allows the use of only the required functional units. Unnecessary modules can be easily excluded, and necessary ones can be just as easily added if desired. The ability to save the "native" functions of the device - measuring voltages and currents - is also available. And, of course, the pointer measuring head can be any other (with a total deflection current of 50 ... 200 µA), this is not important. Further, diagrams and descriptions of individual functional "modules" of the device will be given, and then - structural scheme the entire device and the switching diagram of its individual nodes. All circuits have been repeatedly tested in practice and have shown stable and reliable operation, without complex settings and the use of any specific details. If it is necessary to make a compact device for testing specific components and their parameters, each such circuit-module can be used separately.

Reference frequency generator

A widespread generator circuit based on digital elements was used, which, for all its simplicity, provides a set of required operating frequencies with good accuracy and stability, without requiring any adjustments.

The generator on the K561LA7 (or LE5) microcircuit is synchronized by a quartz resonator in the circuit feedback, which determines the frequency of the signal at its output (conclusions 10, 11), equal in this case to 1 MHz (Figure 1). The generator signal sequentially passes through several stages of frequency dividers by 10, assembled on K176IE4, CD4026 or any other microcircuits. A signal with a frequency ten times lower than the input frequency is taken from the output of each stage. Using any six-position switch, the signal from the generator or any divider can be output. Correctly assembled from serviceable parts, the circuit works immediately and does not need tuning .. With capacitor C1, if desired, you can adjust the frequency within small limits. The circuit is powered by 9 V.

Measurement module L, C

A circuit diagram of a capacitance measurement stage for non-polar capacitors and inductors is shown in Figure 2. The input signal is fed directly from the output of the range switch (SA1 in Figure 1). The formed rectangular pulse signal arriving at the "F" output through the key transistor VT1 can be used to check or configure other devices. The output signal level can be adjusted with resistor R4. This signal is also fed to the measured element - a capacitor or inductance, connected, respectively, to terminals "C" or "L", while the SA2 switch is set to the appropriate position. To the exit "Uizm." the measuring head is connected directly (possibly through an additional resistor; see below "Display module"). Resistor R5 is used to set the measurement limits for inductances, and R6 for capacities. To calibrate the cascade to the terminals "Cx" and "Common" in the range of 1 kHz, we connect an exemplary 0.1 μF capacitor (see the diagram in Figure 1) and with the trimmer R6 set the arrow of the device to the final division of the scale.

Then we connect capacitors, for example, with a capacity of 0.01, 0.022, 0.033, 0.047, 0.056, 0.068 μF and make the appropriate marks on the scale. Then, in the same way, we calibrate the inductance scale, for which in the same range of 1 kHz we connect an exemplary coil with an inductance of 10 mH to the “Lx” and “Common” terminals and set the arrow to the final division of the scale with a trimmer resistor R5. However, it is possible to calibrate the device on any other range (for example, at a frequency of 100 kHz or 100 Hz), connecting as exemplary capacitances and inductances, according to the selected range.

Cascade supply voltage (Usup) - 9 V.

Electrolytic capacitor measurement module (+ C and ESR)

The module is a microfaradometer, in which the capacitance is determined indirectly by measuring the ripple voltage across the resistor R3, which will vary inversely with the capacitance of the periodically recharged capacitor. It is possible to measure the capacitances of oxide (electrolytic) capacitors in the ranges of 10-100, 100-1000 and 1000-10000 uF.

The measuring unit for electrolytic capacitors is assembled on the T1 transistor (Figure 3). The input (R1) is supplied with a signal directly from the output of the generator-divider (circuit in Figure 1), which can be connected in parallel with the previous module. We select resistor R1 depending on the type of transistor T1 used and the sensitivity of the used measuring head. Resistor R2 limits the collector current of the transistor in the event short circuit in the tested capacitor. Unlike other modules, a reduced stable power supply of 1.2 - 1.8 V is required here; The stabilizer circuit for such a voltage will be shown below in Figure 6. It should be noted that during measurements, the polarity of the capacitor connection to the "+ Cx" and "Common" terminals does not matter, and measurements can be performed without removing the capacitors from the circuit. Before starting measurements with resistor R4, the arrow is set to zero (end of the scale).

Before the start of measurements (in the absence of the measured capacitor "+ Cx") by the resistor R4, the arrow is set to zero (the final division of the scale). The "+ Cx" scale can be calibrated on any range. For example, we move the switch SA1 to the position corresponding to the frequency of 1 kHz. Using R4, set the arrow of the device to "0" (end of the scale) and, connecting the reference capacitors with a capacity of 10, 22, 33, 47, 68 and 100 uF to the "+ Cx" and "Common" terminals, make the appropriate marks on the scale. After that, on other ranges (10 Hz and 100 Hz), the same marks will correspond to capacities with denominations 10 and 100 times larger, that is, from 100 to 1000 μF (100, 220, 330, 470, 680 μF) and from 1000 up to 10,000 μF, respectively. Tantalum oxide-semiconductor capacitors with the most stable parameters in time, for example, types K53-1 or K53-6A, can be used as exemplary ones.

The ESR measurement unit contains a separate 100 kHz oscillator, assembled on a 561LA7 (LE5) microcircuit in the same circuit as the main oscillator in Figure 1. Here, special stability is not required, and the frequency can be any from 80 to 120 kHz. The value of the series equivalent resistance of the capacitor connected to the terminals determines the current flowing through the winding I of the transformer (wound on a ferrite ring with a diameter of 15 - 20 mm). The ferrite grade does not matter, but perhaps the number of turns primary winding will need to be corrected. Therefore, it is better to first wind winding II, and the primary winding over it. Straightened constant pressure after the diode VD5 is fed to the measuring head (display module in Figure 4). Diodes VD3, VD4 limit possible voltage surges to protect the switch head from overload. Here, the polarity of the capacitor connection is also not important, and measurements can be carried out directly in the circuit.

The measurement limits can be changed over a wide range with a trimming resistor R5 - from tenths of an Ohm to several Ohms. But you should take into account the effect of the resistance of the wires from the terminals "ESR" and "Common". They should be as short and large as possible. If this module is located close to another source of pulse signals (for example, next to the generator Figure 1), the generation of the node on the microcircuit may be disrupted. Therefore, it is better to assemble the ESR measurement unit on a separate small board and place it in a screen (for example, made of sheet metal), connected to a common wire.

To calibrate the "ESR" scale, connect 0.1, 0.2, 0.5, 1, 2.3 Ohm resistors to the "ESR" and "Common" terminals and make the appropriate marks on the scale. The sensitivity of the device can be adjusted by changing the resistance of the trimmer R5.

The power supply for the ESR meter, like the rest of the module's circuits, is 9 V.

Connection diagram of the device modules

As you can see from Figure 4, connecting all the "modules" is not difficult. The display module includes a measuring head bridged with a capacitor (100 ... 470 μF) to eliminate the “jitter” of the needle when measuring in the ranges with a low frequency of the master oscillator. Additional resistance may be required depending on the sensitivity of the measuring head.

It should be borne in mind that the "Common" terminal in Figure 2 (measurement module "C" and "L") is not a common wire of the circuit (!) And requires a separate socket.

Supplements

Composite transistor T1 (schematic in Figure 3) can be replaced with a node of two lower power transistors if necessary, and a simple single transistor regulator can be used in the 1.4 V power supply. How to do this is shown in Figures 5 and 6. The function of the zener diode here is performed by silicon diodes VD1-VD3 with a total forward voltage drop of about 1.5 V. In contrast to the zener diode, it is necessary to turn on the diodes in the forward direction.

If desired, the device can be supplemented with a module for quick check transistors. It can be used to check any bipolar transistors, and field-effect transistors low and medium power. Moreover, bipolar transistors and, in some cases, field-effect transistors, can be checked without soldering them out of the circuit. The circuit shown in Figure 7 is a combination of a multivibrator and a trigger, where instead of load resistors, transistors with identical parameters, but of opposite structure (VT2, VT3) are included in the collector circuits of the multivibrator transistors. Resistors R6, R7 set the required bias voltage of the operating point of the tested transistor, and R5 limits the current through the LEDs and determines the brightness of their glow.

Depending on the type of LEDs used, you may have to choose the resistance R5, focusing on the optimal brightness of their glow, or put an additional damping resistor in the 9 V supply circuit.It should be noted that this circuit works with a supply voltage starting from 2 V. When nothing is connected to terminals "E", "B", "K", both LEDs are blinking. The blinking frequency can be adjusted by changing the capacitances of the capacitors C1 and C2. When a working transistor is connected to the terminals, one of the LEDs will go out, depending on the type of its conductivity - p-n-p or n-p-n. If the transistor is faulty, both LEDs will flash (internal open) or both will go out (short). In addition to the terminals "E", "B", "K" on the device itself (terminal block, "fragment" of the socket for microcircuits, etc.), you can parallel them remove the corresponding probes from the case on the wires to test the transistors on the boards. When testing field-effect transistors, the terminals "E", "B", "K" correspond to the conclusions "I", "Z", "C".

It should be noted that field-effect transistors or very powerful bipolar transistors are still better to check by removing them from the board.

When measuring the ratings of any elements directly on the board, be sure to turn off the power supply of the circuit in which the measurements are made!

The device takes up little space, fitting in a 140 × 110 × 40 mm case (see the photo on the right at the beginning of the article) and allows you to check almost all the main types of radio components most often used in practice with sufficient accuracy for radio amateurs. The device has been in operation for several years without any complaints.

To comment on materials from the site and receive full access to our forum you need register . |

Calculation of the stability characteristics of the operational communication system

Calculation of the stability characteristics of the operational communication system PDF creator software

PDF creator software Discrete channel. Interference in communication channels

Discrete channel. Interference in communication channels How to use QoS to ensure the quality of Internet access Where is the qos packet scheduler

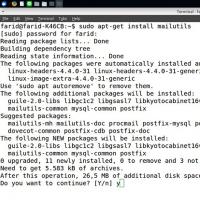

How to use QoS to ensure the quality of Internet access Where is the qos packet scheduler Basic Sendmail Installation and Configuration on Ubuntu Server

Basic Sendmail Installation and Configuration on Ubuntu Server Install VPN in Ubuntu Vpn ubuntu connection

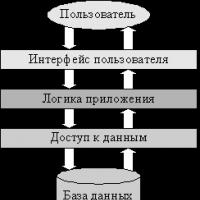

Install VPN in Ubuntu Vpn ubuntu connection Distributed System Architecture Large Scale Cloud IoT Platform

Distributed System Architecture Large Scale Cloud IoT Platform