Winchester performance indicator. HDD performance indicator Hard disk loading indicator

Introduction

Loading indicators that will be discussed are not only an improvement in the appearance, but also carry purely practical benefits.

This article consists of two independent parts: the processor and hard drive loading indicator.

Wincher loading indicator

Before you start creating an indicator, I decided to search the most optimal scheme. Soloing a number of sites, I discovered a relatively small variety of schemes. One of the most important criteria is to get high-quality mod for relatively small money. Most schemes use LM3914 chips that are not so cheap. Therefore, I began to look for a level indicator circuit with 5-8 LEDs. The choice fell on an An6884 due to its lowest price and wide availability. This microcircuit has five LEDs at the output, and passes through each 7MA current.

To read the signal, two wires running from the motherboard are used to which the Winchester indication LED is connected on the front panel. Instead of the LED, the optro input is connected to them (see the scheme). Even if you confuse polarity, nothing burns. The optocoupler on the diagram is necessary for the electrical interchange of the motherboard circuits and the indicator (this is primarily necessary to protect the mat. Fees).

At zero load - the phototransistor inside the optro is locked - at the same time, C6 is discharged through R11. With the increase in the loading of the hard drive - the phototransistor is open, and C6 begins through it through it. The C6 voltage varies proportion to the load level. Depending on the C6 tank, the speed of changing the download level changes.

The C6 voltage is removed through the R12 divider, R14. The R14 trim resistor is used to change the sensitivity of the indicator.

LEDs can be installed anyone and at its discretion. I installed for three smaller levels - green, and for two large - red.

Wincher indicator circuit

Setting the indicator is reduced to the setting of its sensitivity using R14.

Processor loading indicator

When the Winchester indicator was already done, I began to think about the indicator of something else. The choice fell on the processor load indicator.

During the search process, two options were found - via LPT and through COM.

I chose COM port just because it was not involved, unlike LPT. In the search process, I found the Clear66 article in which he talked about connecting the car tachometer to the COM port. I liked this idea most of all that you do not need to do special schemes for converting digital values \u200b\u200binto an analog signal. For control, the PCTACH program is used (link to download - at the end of the article).

But since at hand at that moment it was not at least some tachometer had to make a homemade version of the factory. After assembly and settings, the processor load indicator began to show more or less accurately.

But I did not like the increased speed of displaying the download level, which was expressed by an excessive jerk of the indicator arrows during the uneven loading of the processor. But it was corrected by adding an additional capacitor parallel to the microammeter.

The appearance of the arrow indicator suited me a little, and I decided to look for him an alternative. Ultimately, the indicator became LED, and not a scale of LEDs, but two directions directed towards each other various color of the glow. The display of the load level is made by smoothly changing the brightness of the LEDs.

For the manufacture of the indicator, I used Plexiglas 4-5mm and two LEDs: red and blue glow. From the plexiglas, the strip of 150 mm per 15mm is cut out. After that, the edges of the strips are cut off space for LEDs. Furies and one side of the strip need to be sanded with zero sandpaper to a uniform matte state. It is necessary for uniform dispersion of light. To the back side (which is not processed by sandpaper) and the strips are glued on the sides of the strip to reflect the rays of the LEDs. When the strip is ready - the LEDs are glued.

LED location in plexiglass strip

When the LEDs are already glued - at the ends of the strip, the tape or self-adhesive film is glued. It is necessary so that the LEDs shone only in the desired part of the strip.

Blue top symbolizes cold, i.e. Low load processor. Red bottom symbolizes heating, i.e. Large download. The processor load is proportional to the transition of colors among themselves. The wires going to the board and the resistor of 68-100 ohms are fixed from one edge of the strip using a thermoclaus.

For a smooth change in the brightness of the LEDs, the SHIM signal generation scheme is used. With this control method, the brightness of the LEDs varies from the attitude of the luminescence time and the time when it does not burn. This method is better to control the voltage by the fact that the brightness of the LEDs varies in proportion to the voltage.

The scheme consists of the following blocks:

voltage Shaper on DA1.1

silent Generator on DA2

voltage comparison unit on DA1.2 DA1.3

Resistor divider R4, R3 Sets a voltage of 1.2 volt, which is approximately equal to the minimum voltage of the saw-shaped pulses of DA2. The pulses are removed from the third output of the computer's COM port. With a high input level, the C1 capacitor charges through the R1 resistor and diode D1. With a low input level, the C1 capacitor is discharged through R2. C1 is formed voltage proportional to the processor loading level. Since the amplitude of this voltage is less than the amplitude of the saw-shaped pulses DA2 in the diagram there is an amplifier on DA1.1. Adjusting the maximum level of the indicator is made by changing the gain with R6. The R7 chain, C3 finally smoothes the voltage ripple from the output of the amplifier. PWM is formed by comparing the measured voltage and saw-shaped pulses.

DA1.2 forms direct, and DA1.3 Inverted PWM signal. These two signals further enroll on the LEDs, pre-enhanced by keys on T3, T4 transistors.

Processor indicator circuit

Execution

Since both indicators are located on the front panel - I did a common fee for them. From one edge of the board there are two tracks in the form of strips. Two nuts M3 are soldered to these strips. Two holes 3mm drills ahead in the casing frame so that they match the distance between the centers of nuts on the board. Next to these nuts on the board, two M3 screws are tightened, which pass through the holes in the frame.

Processor loading indicator with different boot levels:

Winches loading indicator with different download levels:

Yesterday, on the onboard panel, the PC was noticed that the reference indicator to the hard disk was constantly and continuously burning in red regardless of the presence or absence of active file operations. Hard disk problems?

The HDD activity indicator is lit while recording data on a hard disk or reading data from a hard disk with a computer. The indicator in particular can constantly burn continuously during the operation of some program for example, the CD player or the compilation of the source code. In the case when the hard disk activity indicator always, constantly and continuously burns in red, regardless of the availability or lack of file operations, this indicates the presence of problems with hard disk or other PC equipment.

With all this, at the time of switching on / starting the computer may depend on the issuing 4 options:

The Debian GNU / Linux 8 is used as an OS on the workstation. Shortly before problems with a permanent luminescence of the HDD activity indicator, there was some kind of glitch with the file system: when the FS is restarted, the READ-only (read only) is constantly transferred to the "Failed to Start Remount root and kernel File Systems. ", But this is a completely different story.

Decision

The block costs 2 HDD (SATA and IDE) on each of which is the OS and there is an appropriate MBR - i.e. Both HDD boot. Search for a problem HDD was solved by the method of their alternate exclusion from the system.

Problem iron

The first SATA (WESTERN DIGITAL, WDC WD5000AAKX) was turned off, the system is loaded with IDE (Seagate), and the problem with the disk activity indicator disappeared. Changing the loops (tump / stick) SATA-interface and SATA-Power on the connectors of the mat. Payment and HDD itself - the problem is completely eliminated, the system has been successfully downloaded from the SATA disk and no "brakes" during POST (Power-On Self-Test ) Testing when starting, as well as no problems with the indicator of the activity of the hard disk are now not observed.

Years pass, contacts are oxidized and the connection between them weakens or disappears at all. In this case, it is possible to say that the problems affected in this topic were directly related to poor contact on the SATA-interface loop IMHO contacts on SATA-nutrition rust do not have time for the simple reason that every 3-4 months from the system unit Completely removed, the power supply, "coolers" with radiators, etc., disassembled and cleales. In this case, the interface loops of the connections of hard drives remained intact (about 3 years).

The morality is that when you next San.teh. The maintenance of the system unit will need to train at the same time to move and interface stumes of hard drives - so as not to rust.

What else can be done if the movement of interface loops does not solve the problem with a hard disk (in order of priority):

If the hard disk in any system unit and on any loops (power supplies) causes problems with the HDD activity indicator, regardless of the availability or lack of active file operations (for example, in safe or single-user mode), then you need:

- Inspect the disk and the state of contacts / loops on its external board;

- From under the deaf DOS, either booting with the Live-CD to perform a complete check of the disk (MHDD, FSCK ETC) for the presence of broken sectors, orphan inodes (orphan inodes) and fix them as possible;

- Full formatting If the search and error correction did not give the result.

Problem in

If there are no problems with the "hardware", and in the other without problems, the working system unit disk does not cause any problems with the indicator, it will be advisable to analyze the activity of the installed software.

If the disk causes problems with the HDD activity indicator only if it is connected as a bootable, then most likely these problems are associated with any malicious process in the system, which starts with the operating system and in this case you need:

- Find a process that executes a lot of read / write file operations and try to disable / kill it;

- Check the system of antivirus.

Well, and if it does not help anything from the above, then it is not enough to use the disk until it is completely molded or to begin to prick the nuts in LJ today - IMHO walking on service centers will no longer buy new HDD purchases;)

Our regular readers are well known for the work of specialists from the Cyber \u200b\u200bSecurity Research Center University of Ben-Gurion (Ben-Gurion University), Israel, which specialize in the invention of unusual hacking methods and the abduction of information from the subsoil of the most secure computer systems. And recently they managed to detect another potential source of information leakage, which is the LED familiar to all of us, which displays the activity of the hard disk of the computer.

We will remind our readers that computers that perform critical operations or containing extensive information in most cases are protected by the so-called "air barrier" method. This means that this computer is not connected itself or other computers connected to networks that have access to the Internet. This makes it impossible ordinary hacker hacking and in order to expect information from the subsoil of such a computer, you need to resort to very sophisticated tricks.

In his studies, researchers found that, programming a certain way a sequence of software appeals to a hard disk of the computer, you can force the LED indicator of activity to flash at a speed of about six thousand times per second. This frequency is quite enough to transmit data at a speed of up to 4 thousand bits per second. Of course, the transfer of one megabyte of data at such a speed will take a little more than half an hour, but in order to transfer stolen messages, passwords, encryption keys and other similar information, it will take quite a bit of time.

To use the hard disk LED as a transmitter, you will need to install on an attacked computer of a special spyware-IT-GO program already developed by Israeli researchers. Currently, the work of this system was tested on computers running the Linux operating system, but researchers are confident that in exactly the same way you can organize the abduction of information and from computers under Windows. A positive feature of this method is that all people have long been accustomed to chaotic flashing of the computer's hard disk indicator and it is unlikely to notice changes in the nature of its work. And the modulation of the luminosity of the LED with a frequency of several kilohertz is far beyond the limits of human eye perception.

But, ensuring information transfer through the hard disk LED is only half of the process of the abduction of information. The second part of the work may take a tiny spy unmanned aerial vehicle equipped with a fast-acting camera and photosensors. The camera lens can be focused exclusively on the computer LED and then sensitivity sensitivity will be enough to remove information even through the tinted glass of the closed window.

There are several options to protect against the embezzlement of information. The simplest option is to disable the LED Hard Disc Indicator. If, due to any reason, it is impossible to do this, then you can position the protected computer so that its LEDs are not visible from any window of this room. And another, more complex option, is the use of a special program that accesss the hard disk at random intervals, it will, in turn, will create insurmountable interference to any other program trying to transfer information through the hard disk LED.

And, as the last measure, Israeli researchers advise simply take the LED indicator with a piece of opaque tape. This method is a bright demonstration of how common and simple materials, such as a piece of conventional tape, can have an effective opposition to the most sophisticated and modern spyware.

One of the common modes of the computer is replacing standard LEDs on the housing to any other. However, you see, it is too simple. Why not make a kind of vu-indicator of loading hard drive on multiple LEDs? Something like VU-meter on amplifiers.

On the above site, a suitable scheme was found:

Everything is simple. Power + 5V, on the left in the diagram. On the right below to the outputs of the Opt stand apartments (legs 1 and 2) connect the conclusions on the mother, called HDD LED. If you confuse polarity on this LED, nothing terrible will happen, just the LEDs will not burn. But at the entrance + 5V polarity is preferably not confused.

The advantage of such a scheme is that the HDD LED signal from the mother is not used by your scheme directly (it is used to change the resistance of the emitter-collector transition of the optotransistor in the optocaster). And, therefore, if you have connected your mother to the right conclusions of the optocouplers, no matter how incorrectly your scheme was not collected, it will never hurt (read: cover) Mom. :-)

Jumper (JUMPER) The diagram defines the mode of operation of the LED scale. If you are closed, the LEDs light up one by one to the right on the left (in the picture), if you open, only one LED will be lit, i.e. It will be something like a "jumping point". Because I did not like the last option, I made a scheme without jumper (just closed this plot).

So, we look ... what we need for this:

- LM3914 itself, actually, microha, controlling LEDs (LED Bargraph Driver Chip);

- 4n25 (or 4N26, or 4N28 or TIL111) - Optocolator (Optoisolator);

- Electrolytic condenser: 220mkf for 25V (we take with a stock in straining);

- Resistors (one-piece): 3.3k, 10kom, 470, 330, all 0.25W.

- LEDs at 2.5-3.5V - 10pcs, cool - multicolored.

Because I found the scheme on the import site, I first decided to collect everything on cardboard and wires to check the performance, check out:

For test purposes, laziness was soldered all 10 LEDs, so only five conclusions from the main microhi are used. If I checked - it worked, this stage you can skip :-).

For convenience, you can still stock the following components:

- Color (black and red) wires for connecting to mom and bp;

- Molex connector for connecting to standard BP; You can buy 2 (dad and mom for mounting on the wire) and make another coupler if there are no free connectors on the BP;

- Thin wires, a train, or a block with cogs on a board for connecting LEDs;

- Cots under chips (18 and 6 legs) - I strongly recommend;

- What will be on all this matter to disperse: a circuit board, foil textolite / getnaks, cardboard (ghetto-mod :-)).

In principle, it is possible to make a pounder, but I didn't stand in this task. Do not forget about the mounting holes in the board, if they need them!

I made a fee as follows. I did not want to bind to chlorine iron, I did not want a varnish and solvent, so I pasted the adhesive pencil on the textolite from the foil side printed on paper in 1: 1 fee (in vain, they were easy to use [adhesive pencil], it provides good adaptation of paper with foil and At the same time, the paper is easily able to be pulled out without applying additional tools). Right so in it drilled holes. He cut off the foil paper, connected the necessary holes with a pencil according to the wiring of the board and cut the track with a knife. Holes for power wires can be made with a diameter of about 1.5mm, if you are going to use standard wires from BP (I did, taking them from the old BP).

In general, there is nothing complicated here, but it is necessary to very carefully solder the narrow tracks, reaching from Microud to LEDs, because There are many and thick them not to do them. Although I at my time was attacked by plenty, but still it was not very simple ... The main thing, after cutting it out well to clean and degrease the fee before soldering. The better read / degrease, it will be easier to pester tin to foil and the less the chance that it will break off from the board. It's better to solder immediately after stripping, and, and immediately all the elements, not postponing the next day, and then if half succeed today and, without treating the fee, leave for a week, then you will have to hemorrhoids to clean the platforms again or harder to warm up with flux, From what, most likely, the tracks will break.

That's what I did:

I decided not to bind to a bunch of LEDs and set a set of ten LEDs in one case, connecting it with a 2-wire loop board by cutting the cable from the drive appropriately. I dropped the train right in the fee, but later I had the idea that I had to install the detachal there.

I highly recommend using cribs under chips. First, do not overheat when soldering on a fee (Microuds are inserted last time), and secondly, if a microme is found with a production marriage (not working, shorter), then it can be easily changed in the store where they bought, and solder you Do not replace.

When you all the job we saved you to check the performance as follows:

- When power is turned on, no LED should burn;

- If you close the contacts 4 and 5 of the optocouplers (those that go to the circuit), then all LEDs (or only the latter, if you collected a scheme with a gap instead of jumper).

If everything has earned, you can experiment, for example, with the order of connecting LEDs, for example, to light first even in the row, and then - odd, etc.

Analog Vinciter loading indicator

For fans of analog technology, it is possible to offer this option:

Those. Instead of a schema and LEDs, you can connect any existing arrow indicator with a decent internal resistance, for example, from some tape recorder. Potentiometer Test current limit. Connect to the HDD-LED connector on your mother. Unlike the previous version, here, if you take a too powerful and not very sensitive device (with low internal resistance), you can easily damage the motherboard and then you will not have any indicator of the HDD.

There are many options for loading the hard disk loading indicators, including digital, but the option that I want to offer you, in my opinion, is one of the easiest.

After spending thirty minutes you can make yourself a small, but interesting mod, which serves not only for visual effects, but can benefit.

All you need for this:

R1- 82K - 1pc.

R2-1 10K -1St.

R3-220 Ohm - 1pc.

C1 -0.1-0.22 μF.

C2-10MCF * 16V.

C3- 47MCF * 16V.

Microcircuit - An6884.

LEDs 5pcs. (Minimum)

Molex power connector (Female) -1pc.

schematic diagram:

The LED connected to the 6th conclusion of the chip must be red (indicates the maximum loading of the railway).

Power supply from 5 to 12V. During the nutrition of 5V, the LEDs are not glowing in full force, this problem can be solved by increasing power up to 12V, but in this case it is necessary to use resistors with a dispersion capacity of 1 or 5 W (resistors by 0.5 W and less can burn) and connect the LEDs through restrictive Resistors 470-510. If 5V LEDs, then you can do without restrictive resistors.

All items cost me at 60 rubles. (It all depends on the LEDs that you are going to use) LEDs were used for 5V rectangular shape, after the end of the assembly, I fed them into the LED line. In Chelyabinsk microcircuit an6884 costs about 8 rubles.

Assembly:

The soldering must be soldered with a soldering iron not more powerful than 40W, each contact is to solder no more than 3-4 seconds and put a deposit just in case to protect your money. When soldering resistors, it is best to use tweezers, because they are very quickly heated, besides, the tweezers will distinguish heat from the contacts.

If you do not have big experience in the assembly, then try to first collect everything on the cardboard, and then you can try on the circuit board.

All items (except LEDs and Capacitor C3) I collected on a separate board. To reduce the number of wires connecting LEDs and fee, I fed together all the cathodes of LEDs and soldered C3 directly to them.

Connection and configuration

I connected the indicator input directly to the cathode of the LED displayed to the front panel of the system unit, and the board attached there under the panel. The power anode can be attached to the system of the system (yellow wire in the figure), the cathode to Molex (red wire). So you can save space inside the system unit and reduce the number of wires.

After connecting the power, touch the scheme input with your finger, then 1-2 level (or all the scale is completely), it means that the indicator works.

The setting is reduced to the recruitment of the R1 resistor, it is responsible for the sensitivity of the indicator, it is best to connect a variable resistor with R1 with R1. It will make it much easier for the setting if you do not suit the indicator sensitivity level.

To build the number of LEDs, you can connect 2-3 pieces for one level by connecting them in parallel.

Output

You can apply this small scheme in any device, you can install it instead of the CD-ROM indicators and in Mobile Rack or connect to the output of the sound card, and in general it can be applied almost everywhere.

Thanks to a simple scheme, it can even collect a person who does not know anything about the circuitry and tune here almost nothing. The only drawback of this scheme is that the larger the LED works, the dull, each of them is lit, but at high supply voltage it is not noticeable.

Some usefulness. The presence of two indicators I have already helped several times. For example, once again do not reboot the computer (there was a suspicion that he was hung - but the indicator was twitching - and after 5 minutes the computer is breaking!). Or, on the contrary, boldly harvest reset - the loading LED glows constantly, and the peak was on zero - the right sign Hang`a.

Cellular - what it is on the iPad and what's the difference

Cellular - what it is on the iPad and what's the difference Go to digital television: What to do and how to prepare?

Go to digital television: What to do and how to prepare? Social polls work on the Internet

Social polls work on the Internet Savin recorded a video message to the Tyuments

Savin recorded a video message to the Tyuments Menu of Soviet tables What was the name of Thursday in Soviet canteens

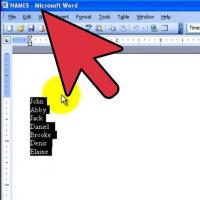

Menu of Soviet tables What was the name of Thursday in Soviet canteens How to make in the "Word" list alphabetically: useful tips

How to make in the "Word" list alphabetically: useful tips How to see classmates who retired from friends?

How to see classmates who retired from friends?