Catenary suspension on the railway. Contact network - what is it? Features of contact networks of a railway, tram or trolleybus. Requirements for overhead point switches

POWER SUPPLY DEVICES

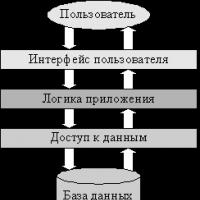

V system of electrified railways of Russia(Fig. 1) includes structures and devices that make up its outer part (thermal, hydraulic and nuclear power plants, power lines) and the traction part (traction substations, contact network, rail circuit, supply and suction lines).

Fig.1 “General view of the electrified DC railway and its power supply devices: 1- power plant; 2 - step-up transformer; 3 - high-voltage switch; 4 - power line; 5 - traction substation; 6 - block of high-speed switches and disconnectors; 7 - suction line; 8 - supply line; 9 - rectifier; 10 - traction transformer; 11 - high-voltage switch; 12 - spark gap.

Power plants a three-phase current with a voltage of 220-380 V is generated, which is then increased at substations for transmission over long distances.

Near places of electricity consumption, the voltage is reduced by transformer substations up to 220 kV and supplied to regional high-voltage networks, to which electricity consumers are connected, including traction substations of electrified railways that supply the contact network.

Electrified railways Russia operate on direct or single-phase alternating current.

Relatively low voltage is the main disadvantage of the DC system. To maintain the required voltage level at the locomotive pantographs, traction substations are placed at a distance of 10-25 km. On lines with a high load density and heavy passenger traffic, it is necessary not only to reduce the distance between substations, but also to increase the cross-section of the contact network (an additional contact wire is suspended).

AC traction substations serve only to lower the alternating current voltage received from power grids to 27.5 kV.

Contact network is designed to transfer electrical energy received from traction substations to electric rolling stock and must ensure reliable current collection at the highest speeds in any atmospheric conditions.

There are various designs of the contact network for ground electric transport and subways. On our railways, a structure is adopted (Fig. 2), the main elements of which are supports; overhead catenary consisting of a carrying cable, contact and reinforcing wires; consoles, clamps, etc.

Fig.2. The device of the contact network on a double-track section: 1 - carrying cable; 2 - contact wire; 3 - reinforcing wire; 4 - string; 5 - retainer; 6 - console; 7 - support.

Fig. 3 Single chain suspension: 1 - console; 2 - carrying cable; 3 - strings; 4 - insulator; 5 - contact wire; 6 - retainer.

Supports made of reinforced concrete or metal are located along the railway track at a distance of 65-80 m from each other.

The consoles are reinforced at the top of the supports. A copper or bimetallic supporting cable is suspended from them on insulators.

Contact wire made of copper and suspended by strings from a bimetallic or copper support cable. The distance between the strings is usually 6-12 m.

On straight sections of the track, contact wires are arranged in a zigzag manner relative to the track axis by 300 mm in each direction (Fig. 4). This is necessary to ensure uniform wear of the pantograph linings of the electric rolling stock.

Fig. 4 The location of the contact wire in straight sections

This arrangement of the contact wire is carried out using clamps located on each support. The clamps also prevent the overhead from swinging from the side wind.

To reduce the sag of the contact wire with seasonal temperature changes, it is pulled to the supports, which are called anchor, and cargo compensators are suspended through the system of blocks and insulators (Fig. 5.).

Fig.5 Conjugation of anchor sections: 1,4 - anchor supports; 2,3 - transitional supports; I, II - contact suspensions of mating anchor sections

The height of the overhead wire suspension above the level of the top of the rail head must be at least 5750 mm and not exceed 6800 mm.

For reliable operation of the contact network and ease of maintenance, it is divided into separate sections (sections) using air gaps and neutral inserts (insulating couplings), as well as sectional and cut-in insulators.

When the current collector of the electric rolling stock passes through the air gap, it briefly electrically connects both sections of the contact network. If, according to the power supply conditions of the sections, this is unacceptable, then they are separated by a neutral insert, which consists of several sequentially connected gaps (Fig. 6).

Fig.6 Neutral insert: 1 - additional contact suspension; 2,3 - sectional disconnectors; 4.5 - warning signals; I, II - contact suspensions of mating anchor sections.

The use of such inserts is necessary in AC sections, when adjacent sections are powered from different phases of three-phase current. The length of the neutral insert is set in such a way that at any positions of the raised pantographs of the electric rolling stock, the simultaneous closure of the contact wires of the neutral insert with the wires of the adjacent sections of the contact network is completely excluded.

3.2 RAILWAY POWER SUPPLY FACILITIES, GOVERNANCE ORGANIZATION AND POWER SUPPLY FACTORIES

The management of the power supply industry for all railways and industrial enterprises of railway transport is carried out by Department of Electrification and Power Supply of JSC "Russian Railways"... The main tasks of the Department are to ensure the uninterrupted operation of power supply devices, the development of the power supply base, and the development of plans for the electrification of railways.

The Department carries out operational and technical management of the railway power supply services, the most important task of which is the uninterrupted supply of electricity to electrified sections of the road and consumers of electricity in all sectors of the road economy, as well as all other consumers connected to the road's power grids.

The services carry out their activities through linear enterprises - power supply distances.

V power supply distance functions includes:

· Reception of electrical energy from the unified electrical network of the country and its supply to the contact network;

Topic: what voltage is supplied to the railway contact network, railway power supply.

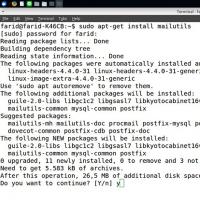

Railway transport consumes about 7% of the electricity generated by the power plants in Russia. Most of it is spent on the movement of trains (their traction), as well as immovable objects (depots, stations, workshops and systems for regulating the movement of railway transport). In addition, settlements (small) and industrial enterprises located nearby can be connected to the railway power supply system. The power supply system of railways (electrified) consists of an external part (power stations, transformer substations, power grids and power transmission lines) and traction (traction substations and a traction power grid).

Power plants (thermal, nuclear, water) produce three-phase alternating electric current with a voltage of 6-21 kV and a standard frequency of 50 Hz. To transmit electricity, the voltage at the substations is increased to 750 kV (the value depends on the distance between the station and the consumer). Near the consumers of electrical energy themselves, the voltage is reduced to 110-220 kV and is supplied to the regional power grids, to which traction electrical substations of railways (electrified) and electrical substations of roads with fuel (heat) traction are also connected.

Any disruption to the normal power supply of the railways leads to interruptions in the planned movement of rolling stock. In order to provide high-quality reliable power supply to the traction power grid of railway transport, it is usually provided in advance for its electrical connection to two different independent sources of electricity. Sometimes power supply is allowed from 2 single-circuit power supply lines or one double-circuit.

Sections of the electrical contact network are powered from neighboring traction electrical substations. This makes it possible to more evenly load traction electrical substations and the contact power grid, which helps to reduce various losses of electrical energy in the traction electrified network.

As you know, in Russia, 2 power supply systems are used on the railways: alternating single-phase current and direct current. Electric traction on an alternating three-phase current has not received practical distribution, since it is technically very difficult to isolate (protect) the power wires of two different phases of the contact network located close to it (the third phase is the rails themselves).

The rolling stock (electric) is provided with special DC traction motors, since the proposed models of AC motors do not meet certain requirements for reliability and power. For this reason, the railway lines are supplied with an alternating single-phase current system, and special electrical equipment is installed on the trains (locomotives) themselves, which converts the alternating single-phase current into direct current.

The nominal voltage values supplied to the current collectors of the rolling stock are regulated: 25 kV - at alternating current and 3 kV - at constant current. At the same time, there are permissible fluctuations in electrical voltage: with alternating current - 21-29 kV and with constant current - 2.7-4 kV. In certain areas, an electrical voltage level of at least 19 kV at alternating current and 2.4 kV at constant current may be allowed.

On electrified railways operating on direct current, power traction electrical substations perform 2 tasks: they reduce the voltage of the three-phase current and transform it into direct current. All electrical equipment that supplies alternating electric current is located in an open space, and power rectifiers and additional systems are located in closed rooms. From traction electrical substations, energy enters the overhead power grid through a supply line, which is called a feeder.

P.S. The power supply of the railway is due to its own characteristics due to the specifics of this transport itself. In different areas and for different vehicles, it is more rational to use your type of electric current and voltage value. This is what achieves the maximum efficiency and reliability of power supply for railway transport.

Contact network is a set of devices for transmitting electricity from traction substations to EPS through current collectors. It is part of the traction network and for rail electrified transport usually serves as its phase (with alternating current) or pole (with direct current); the other phase (or pole) is the rail network. The catenary can be made with a catenary rail or with a catenary.

In a contact network with a catenary, the main elements are: wires - an overhead wire, a carrying cable, a reinforcing wire, etc.; supports; supporting and fixing devices; flexible and rigid cross-members (consoles, clamps); insulators and fittings for various purposes.

An overhead catenary is classified according to the types of electrified transport for which it is intended - railway. mainline, city (tram, trolleybus), quarry, mine underground rail transport, etc.; by the nature of the current and the rated voltage of the EPS supplied from the network; on the placement of the contact suspension relative to the axis of the rail track - for central current collection (on mainline railway transport) or lateral (on industrial transport tracks); by types of overhead catenary - with simple, chain or special; according to the peculiarities of the anchoring of the contact wire and the supporting cable, the interface of the anchor sections, etc.

The overhead contact network is designed to work outdoors and is therefore subject to climatic factors, which include: ambient temperature, humidity and air pressure, wind, rain, frost and ice, solar radiation, and various contaminants in the air. To this it is necessary to add thermal processes arising from the flow of traction current through the network elements, the mechanical effect on them from the pantographs, electrocorrosion processes, numerous cyclic mechanical loads, wear, etc. quality of current collection in any operating conditions.

Unlike other power supply devices, the contact network does not have a reserve, therefore, increased reliability requirements are imposed on it, taking into account which its design, construction and installation, maintenance and repair are carried out.

Contact network design

When designing a contact network (KS), the number and brand of wires are selected based on the results of calculations of the traction power supply system, as well as traction calculations; determine the type of catenary in accordance with the maximum speeds of movement of the EPS and other conditions of current collection; find the length of the span (ch. arr. according to the conditions for ensuring its wind resistance, and at high speeds of movement - and a given level of uneven elasticity); choose the length of the anchor sections, types of supports and supporting devices for spans and stations; develop designs for compressor stations in artificial structures; place supports and draw up plans for the overhead network at stations and railway tracks with the coordination of wire zigzags and taking into account the execution of air switches and elements of the overhead circuit sectioning (insulating couplings of anchor sections and neutral inserts, sectional insulators and disconnectors).

The main dimensions (geometric indicators) characterizing the location of the contact network relative to other devices are the height H of the contact wire hanging above the level of the top of the rail head; distance A from live parts to grounded parts of structures and rolling stock; the distance Г from the axis of the extreme path to the inner edge of the supports, located at the level of the rail heads, is regulated and largely determines the design implementation of the elements of the contact network (Fig. 8.9).

The improvement of overhead contact network structures is aimed at increasing its reliability while reducing the cost of construction and operation. Reinforced concrete supports and foundations of metal supports are made with protection against electro-corrosive effects on their reinforcement of stray currents. An increase in the service life of contact wires is achieved, as a rule, by using inserts with high antifriction properties on pantographs (carbon, including metal-containing; cermet, etc.), by choosing a rational design of pantographs, as well as by optimizing current collection modes.

To increase the reliability of the contact network, ice melting is carried out, incl. without interruption of train traffic; use wind-resistant contact suspensions, etc. The efficiency of work on the contact network is facilitated by the use of telecontrol for remote switching of sectional disconnectors.

Wire anchoring

Wire anchoring - attaching the wires of the catenary through the insulators and fittings included in them to the anchor support with the transfer of their tension to it. Anchoring of wires can be uncompensated (rigid) or compensated (Fig. 8.16) through a compensator that changes the length of the wire in the event of a change in its temperature while maintaining a given tension.

In the middle of the anchor section of the catenary, an average anchorage is performed (Fig. 8.17), which prevents unwanted longitudinal displacements towards one of the anchors and allows you to limit the damage zone of the catenary when one of its wires breaks. The medium anchoring cable is attached to the contact wire and the supporting cable with appropriate fittings.

Wire strain compensation

Compensation of the tension of wires (automatic regulation) of the contact network when changing their length as a result of temperature effects is carried out by compensators of various designs - block-cargo, with drums of various diameters, hydraulic, gas-hydraulic, spring, etc.

The simplest is a block-cargo compensator, consisting of a load and several blocks (chain hoist), through which the load is connected to the anchored wire. The most widespread is a three-block compensator (Fig. 8.18), in which a fixed block is fixed on a support, and two movable ones are embedded in loops formed by a cable carrying a load and fixed with the other end in the stream of a fixed block. The anchored wire is attached to the movable block through insulators. In this case, the weight of the load is 1/4 of the nominal tension (a gear ratio of 1: 4 is provided), but the movement of the load is twice that of a two-to-six-piece expansion joint (with one movable block).

compensators with drums of different diameters (Fig. 8.19), cables connected with anchored wires are wound on a small diameter drum, and a cable connected to a garland of goods is wound on a larger diameter drum. The braking device is used to prevent damage to the catenary when the wire breaks.

Under special operating conditions, especially with limited dimensions in artificial structures, insignificant temperature drops in heating wires, etc., compensators of other types are also used for overhead catenary wires, fixing cables and rigid crossbars.

Catch wire

Catenary wire latch - a device for fixing the position of the catenary wire in the horizontal plane relative to the pantograph axis. On curved sections, where the levels of the rail heads are different and the axis of the pantograph does not coincide with the axis of the track, non-articulated and articulated clamps are used. The non-articulated retainer has one rod that pulls the contact wire from the pantograph axis to the support (stretched retainer) or from the support (compressed retainer) by the size of the zigzag. On electrified railways non-articulated clamps are used very rarely (in the anchored branches of the catenary, on some air switches), since the "hard point" formed with these clamps on the contact wire worsens the current collection.

The articulated latch consists of three elements: the main rod, the stand and an additional rod, at the end of which the fixing clip of the contact wire is attached (Fig. 8.20). The weight of the main rod is not transferred to the overhead wire, and it only takes a part of the weight of the additional rod with a fixing clip. The rods are shaped to ensure reliable passage of the pantographs when they are squeezed out of the contact wire. For high-speed and high-speed lines, lightweight additional rods are used, for example, made of aluminum alloys. With a double contact wire, two additional rods are installed on the rack. On the outer side of the curves of small radii, flexible clamps are mounted in the form of a conventional additional rod, which is attached through a cable and an insulator to a bracket, a rack or directly to a support. On flexible and rigid cross-beams with fixing cables, strip clamps (by analogy with an additional rod) are usually used, hinged by clamps with an eye mounted on the fixing cable. On rigid cross-members, you can also attach clips to special racks.

Anchor section

Anchor section - a section of a contact suspension, the boundaries of which are anchor supports. The division of the contact network into anchor sections is necessary for the inclusion of devices in the wires that maintain the tension of the wires when their temperature changes and for the implementation of the longitudinal sectioning of the contact network. This division reduces the damage zone in case of wire breakage of the overhead catenary, facilitates installation, tech. maintenance and repair of the contact network. The length of the anchor section is limited by permissible deviations from the nominal value of the tension of the catenary wires set by the compensators.

Deviations are caused by changes in the position of strings, clips and brackets. For example, at speeds up to 160 km / h, the maximum length of the anchor section with bilateral compensation on straight sections does not exceed 1600 m, and at speeds of 200 km / h no more than 1400 m is allowed. In curves, the length of the anchor sections decreases the more, the longer the length curve and its radius is smaller. To move from one anchor section to the next, non-insulating and insulating mates are performed.

Pairing anchor sections

Conjugation of anchor sections is a functional combination of two adjacent anchor sections of a catenary, which ensures a satisfactory transition of the EPS current collectors from one of them to another without disturbing the current collection mode due to the corresponding placement in the same (transitional) spans of the contact network of the end of one anchor section and the beginning of the other. A distinction is made between non-insulating interfaces (without electrical sectioning of the contact network) and insulating (with sectioning).

Non-insulating mates are performed in all cases when it is required to include compensators in the catenary wires. This achieves mechanical independence of the anchoring sections. Such mates are mounted in three (Fig. 8.21, a) and less often in two spans. On high-speed lines, interfaces are sometimes performed in 4-5 spans due to higher requirements for the quality of current collection. On non-insulating mates, there are longitudinal electrical connectors, the cross-sectional area of which must be equivalent to the cross-sectional area of the wires of the contact network.

Insulating interfaces are used when it is necessary to section the contact network, when, in addition to the mechanical, it is necessary to ensure the electrical independence of the mating sections. Such mates are arranged with neutral inserts (sections of the overhead catenary, on which there is no normal voltage) and without them. In the latter case, three or four-span interfaces are usually used, placing the contact wires of the mating sections in the middle span (spans) at a distance of 550 mm from one another (Fig. 8.21.6). In this case, an air gap is formed, which, together with insulators included in the raised contact hangers at the transitional supports, ensures the electrical independence of the anchor sections. The transition of the current collector runner from the contact wire of one anchor section to another occurs in the same way as with non-insulating mating. However, when the pantograph is in the middle span, the electrical independence of the anchoring sections is impaired. If such a violation is unacceptable, neutral inserts of different lengths are used. It is chosen such that with several raised pantographs of one train, the simultaneous overlap of both air gaps is excluded, which would lead to a short circuit of the wires powered from different phases and under different voltages. Pairing with a neutral insert in order to avoid burnout of the contact wire of the EPS runs freewheel, for which a signal sign "Disconnect the current" is installed 50 m before the start of the insert, and after the end of the insert with electric locomotive traction after 50 m and with multiple unit traction after 200 m - the sign " Switch on the current "(Fig. 8.21, c). In areas with high-speed traffic, automatic means of switching off the current at the EPS are required. In order to be able to take the train out when it is forced to stop under the neutral insert, sectional disconnectors are provided for temporarily supplying voltage to the neutral insert from the side of the train's direction of travel.

Overhead sectioning

Sectioning of the contact network - the division of the contact network into separate sections (sections), electrically disconnected by insulating interfaces of anchor sections or sectional insulators. The insulation can be broken during the passage of the ERS pantograph along the section boundary; if such a short circuit is unacceptable (when supplying adjacent sections from different phases or belonging to different traction power supply systems), neutral inserts are placed between the sections. Under operating conditions, the electrical connection of individual sections is carried out, including sectional disconnectors installed in appropriate places. Sectioning is also necessary for the reliable operation of power supply devices as a whole, operational maintenance and repair of the contact network with voltage disconnection. The sectioning scheme provides for such a mutual arrangement of sections in which the disconnection of one of them has the least effect on the organization of train traffic. Sectioning of the contact network is longitudinal and transverse. With longitudinal sectioning, the contact network of each main track is divided along the electrified line at all traction substations and sectioning posts. In separate longitudinal sections, the contact network of spans, substations, sidings and overtaking points is distinguished. At large stations with several electrified parks or groups of tracks, the contact network of each park or group of tracks forms independent longitudinal sections. At very large stations, the contact network of one or both necks is sometimes separated into separate sections. The contact network is also sectioned in long tunnels and on some bridges with a ride from below. With transverse sectioning, the contact network of each of the main tracks is divided along the entire length of the electrified line. At stations with significant track development, additional cross sectioning is used. The number of cross sections is determined by the number and purpose of individual tracks, and in some cases by the modes of starting the EPS, when it is necessary to use the cross-sectional area of the contact suspensions of adjacent tracks.

Sectioning with compulsory grounding of the disconnected section of the contact network is provided for tracks on which people can be on the roofs of cars or locomotives, or tracks near which lifting and transport mechanisms (loading and unloading, outfitting tracks, etc.) work. To ensure greater safety of those working in these places, the corresponding sections of the contact network are connected to other sections by sectional disconnectors with earthing knives; these blades ground the sections to be switched off when the disconnectors are opened.

In fig. 8.22 shows an example of a power supply and sectioning scheme for a station located on a double-track section of an AC electrified line. The diagram shows seven sections - four on the tracks and three at the station (one of them with mandatory grounding when it is turned off). The contact network of the left-haul and station tracks receives power from one phase of the power system, and the right-haul tracks - from the other. Correspondingly, sectioning is performed using insulating mates and neutral inserts. In areas where ice melting is required, two sectional disconnectors with motor drives are installed on the neutral insert. If ice melting is not foreseen, one manually operated sectional disconnector is sufficient.

Sectional insulators are used for sectioning the contact network of the main and lateral networks at the stations. In some cases, sectional insulators are used to form neutral inserts on the AC contact network, which the ERS passes without consuming current, as well as on paths where the length of the ramps is not sufficient to accommodate the insulating couplings.

The connection and disconnection of various sections of the contact network, as well as the connection to the supply lines, is carried out using sectional disconnectors. On AC lines, as a rule, horizontal-rotary disconnectors are used, on DC lines - vertical-chopping disconnectors. The disconnector is controlled remotely from the consoles installed in the duty station of the contact network area, in the premises of the station attendants and in other places. The most critical and frequently switched disconnectors are installed in the dispatch telecontrol network.

There are longitudinal disconnectors (for connecting and disconnecting the longitudinal sections of the contact network), transverse (for connecting and disconnecting its transverse sections), feeder, etc. They are designated by letters of the Russian alphabet (for example, longitudinal -A, B, C, D; transverse - P ; feeder - Ф) and numbers corresponding to the numbers of tracks and sections of the contact network (for example, P23).

To ensure the safety of work on the disconnected section of the contact network or near it (in the depot, on the paths for equipping and inspecting the roof equipment of the EPS, on the ways of loading and unloading cars, etc.), disconnectors with one grounding knife are installed.

Frog

Air arrow - formed by the intersection of two contact suspensions above the turnout switch; is designed to ensure smooth and reliable passage of the pantograph from the overhead wire of one path to the overhead wire of the other. The crossing of wires is carried out by superimposing one wire (as a rule, an adjoining path) on another (Fig. 8.23). To lift both wires when the pantograph approaches the air arrow, a restrictive metal pipe 1-1.5 m long is fixed on the lower wire. The upper wire is placed between the tube and the lower wire. The intersection of the contact wires over a single turnout switch is carried out with the displacement of each wire to the center from the track axes by 360-400 mm and located where the distance between the inner edges of the heads of the connecting rails of the cross is 730-800 mm. At cross point switches and with the so-called. blind intersections, the wires are crossed over the center of the turnout or intersection. Air arrows are usually fixed. To do this, clamps are installed on the supports that hold the contact wires in a given position. On station tracks (except for the main tracks), the arrows can be made unfixed if the wires above the turnout are located in the position specified by the adjustment of the zigzags at the intermediate supports. The catenary strings located near the arrows must be double. The electrical contact between the catenary hangers forming the air arrow is provided by an electrical connector installed at a distance of 2-2.5 m from the point of intersection on the side of the point. To increase reliability, arrow designs are used with additional cross connections between the wires of both contact suspensions and sliding supporting double strings.

Contact network supports

Contact network supports - structures for fixing the supporting and fixing devices of the contact network, taking the load from its wires and other elements. Depending on the type of the supporting device, the supports are divided into cantilever supports (single-track and double-track versions); racks of rigid cross-members (single or paired); Supports for flexible beams; feeder (with brackets only for supply and suction wires). Supports on which there are no supporting, but there are fixing devices, are called fixing. The cantilever supports are divided into intermediate ones - for attaching one overhead catenary; transitional, installed at the interface of the anchor sections, - for fastening two contact wires; anchor, receiving the force from the anchoring of wires. As a rule, supports perform several functions simultaneously. For example, the support of the flexible beam can be anchored, and consoles can be suspended on the posts of the rigid beam. Brackets for reinforcement and other wires can be attached to the support posts.

Supports are made of reinforced concrete, metal (steel) and wood. On domestic railways. e. mainly used supports made of prestressed reinforced concrete (Fig. 8.24), conical centrifuged, standard length 10.8; 13.6; 16.6 m. Metal supports are installed in cases where it is impossible to use reinforced concrete in terms of bearing capacity or dimensions (for example, in flexible crossbars), as well as on lines with high-speed movement, where increased requirements are imposed on the reliability of support structures. Wooden supports are used only as temporary ones.

For DC sections, reinforced concrete supports are made with additional bar reinforcement located in the foundation part of the supports and designed to reduce damage to the support reinforcement by electrocorrosion caused by stray currents. Depending on the method of installation, reinforced concrete supports and racks of rigid cross-members can be separate and inseparable, installed directly into the ground. The required stability of the inseparable supports in the ground is ensured by the upper bed or base plate. In most cases, inseparable supports are used; separate ones are used in case of insufficient stability of inseparable ones, as well as in the presence of groundwater that complicates the installation of inseparable supports. In anchor reinforced concrete supports, guys are used, which are installed along the path at an angle of 45 ° and attached to reinforced concrete anchors. Reinforced concrete foundations in the above-ground part have a glass with a depth of 1.2 m, in which supports are installed and then the sinuses of the glass are sealed with cement mortar. For deepening foundations and supports into the ground, the vibration immersion method is mainly used.

Metal supports of flexible crossbars are usually made of a tetrahedral pyramidal shape, their standard lengths are 15 and 20 m. Longitudinal vertical posts made of angular rolled products are connected by a triangular lattice, also made of a corner. In areas characterized by increased atmospheric corrosion, metal cantilever supports 9.6 and 11 m long are fixed in the ground on reinforced concrete foundations. The cantilever supports are installed on prismatic three-beam foundations, the supports for flexible crossbars are either on separate reinforced concrete blocks or on pile foundations with grillages. The base of the metal supports is connected to the foundations with anchor bolts. To fix supports in rocky soils, heaving soils of permafrost and deep seasonal freezing regions, in weak and swampy soils, etc., the foundations of special structures are used.

Console

Console is a supporting device fixed on a support, consisting of a bracket and a rod. Depending on the number of overlapping paths, the console can be one-, two-, and less often multi-path. To eliminate the mechanical connection between contact suspensions of different paths and to increase reliability, single-track consoles are more often used. Non-insulated or grounded consoles are used, in which insulators are located between the supporting cable and the bracket, as well as in the retainer rod, and insulated consoles with insulators located in the brackets and rods. Non-insulated consoles (fig. 8.25) in shape can be curved, inclined and horizontal. For supports installed with an increased size, consoles with struts are used. At the junctions of the anchor sections, when mounting on one support of two consoles, a special traverse is used. Horizontal consoles are used in cases where the height of the supports is sufficient to secure the inclined rod.

With insulated consoles (Fig. 8.26), it is possible to carry out work on a supporting cable near them without disconnecting the voltage. The absence of insulators on non-insulated consoles ensures greater stability of the position of the carrying cable under various mechanical influences, which has a beneficial effect on the current collection process. The brackets and rods of the consoles are attached to the supports with the help of anchors that allow them to be rotated along the track axis by 90 ° in both directions relative to the normal position.

Flexible cross member

Flexible crossbar - a supporting device for hanging and fixing overhead wires located over several tracks. A flexible cross member is a system of cables stretched between the supports across the electrified tracks (Fig. 8.27). The transverse load-bearing cables take up all vertical loads from the wires of the chain suspensions, the cross member itself and other wires. The sag arrow of these cables must be at least Vio of the span between the supports: this reduces the effect of temperature on the height of the catenary hangers. To increase the reliability of the crossbars, at least two transverse load-bearing cables are used.

The fixing cables perceive horizontal loads (the upper one - from the load-bearing cables of the chain hangers and other wires, the lower one - from the contact wires). Electrical isolation of the cables from the supports allows maintenance of the contact network without disconnecting the voltage. All cables to adjust their length are fixed on the supports using threaded steel rods; in some countries, special dampers are used for this purpose, mainly for attaching an overhead catenary at stations.

Current collection

Current collection is the process of transferring electrical energy from an overhead wire or contact rail to electrical equipment of a moving or stationary ERS through a pantograph, which provides a sliding (on mainline, industrial and most of urban electric transport) or rolling (on some types of ERS of urban electric transport) electrical contact. Breaking the contact during current collection leads to the occurrence of non-contact electric arc erosion, which results in intense wear of the contact wire and contact inserts of the current collector. When the points of contact are overloaded with current in the driving mode, contact electroexplosive erosion (sparking) and increased wear of the contacting elements occur. Prolonged overload of the contact with the operating current or short-circuit current when the ERS is parked can lead to burnout of the contact wire. In all these cases, it is necessary to limit the lower limit of contact pressure for the given operating conditions. Excessive contact pressure, incl. as a result of the aerodynamic effect on the pantograph, an increase in the dynamic component and the increase in the vertical deflection of the wire caused by them, especially at the clamps, on the air switches, at the junctions of the anchor sections and in the area of artificial structures, can reduce the reliability of the contact network and pantographs, as well as increase the wear rate wires and contact inserts. Therefore, the upper limit of contact pressure also needs to be normalized. Optimization of current collection modes is ensured by coordinated requirements for overhead line devices and pantographs, which guarantees high reliability of their operation at minimum reduced costs.

The quality of current collection can be determined by different indicators (the number and duration of mechanical contact violations on the calculated track section, the degree of contact pressure stability close to the optimal value, the wear rate of contact elements, etc.), which largely depend on the design of the interacting systems - the contact network and pantographs, their static, dynamic, aerodynamic, damping and other characteristics. Despite the fact that the current collection process depends on a large number of random factors, the research results and operating experience make it possible to identify the fundamental principles of creating current collection systems with the required properties.

Rigid cross member

Rigid crossbar - serves to suspend the wires of the contact network located over several (2-8) paths. A rigid crossbeam is made in the form of a block metal structure (crossbar), installed on two supports (Fig. 8.28). Such cross-members are also used for the span to be opened. The crossbar with struts is hinged or rigidly connected by means of struts, allowing it to unload in the middle of the span and reduce steel consumption. When placing lighting fixtures on the crossbar, a flooring with a handrail is performed on it; provide a ladder for climbing the support staff. Install rigid cross members Ch. arr. at stations and separate points.

Insulators

Insulators are devices for insulating live wires of the contact network. There are insulators according to the direction of application of loads and the place of installation - suspended, tension, fixing and cantilever; by design - poppet and rod; by material - glass, porcelain and polymer; insulators also include insulating elements

Suspended insulators - porcelain and glass discs - are usually connected in strings of 2 on DC lines and 3-5 (depending on air pollution) on AC lines. Tension insulators are installed in wire anchors, in carrying cables above sectional insulators, in fixing cables of flexible and rigid crossbars. Retaining insulators (Fig. 8.29 and 8.30) differ from all others by the presence of an internal thread in the hole in the metal cap for securing the pipe. On AC lines, rod insulators are usually used, and DC insulators are also used with poppet insulators. In the latter case, another disc-shaped insulator with an earring is included in the main rod of the articulated retainer. Cantilever porcelain rod insulators (Fig. 8.31) are installed in struts and rods of insulated consoles. These insulators must have increased mechanical strength, since they work in bending. In sectional disconnectors and horn arresters, porcelain rod insulators are usually used, less often disc-shaped insulators. In sectional insulators on DC lines, polymer insulating elements are used in the form of rectangular bars made of press material, and on AC lines, in the form of cylindrical fiberglass rods, on which electro-protective covers made of fluoroplastic pipes are worn. Polymer rod insulators with fiberglass cores and silicone elastomer ribs have been developed. They are used as suspended, sectioning and fixing; they are promising for installation in struts and rods of insulated consoles, in cables of flexible crossbars, etc. In areas of industrial air pollution and in some artificial structures, periodic cleaning (washing) of porcelain insulators is carried out using special mobile means.

Contact suspension

An overhead catenary is one of the main parts of an overhead contact network, it is a system of wires, the relative position of which, the method of mechanical connection, material and cross section provide the required quality of current collection. The design of the overhead catenary (KP) is determined by economic feasibility, operating conditions (maximum speed of movement of the EPS, the greatest current taken by pantographs), climatic conditions. The need to ensure reliable current collection at increasing speeds and power of the EPS has determined the trends in the design of suspensions: first, simple, then single with simple strings and more complex - spring single, double and special, in which to ensure the required effect, Ch. arr. alignment of the vertical elasticity (or stiffness) of the suspension in the span, space-cable-stayed systems with an additional cable or others are used.

At speeds up to 50 km / h, a satisfactory quality of current collection is provided by a simple overhead catenary, consisting only of a contact wire suspended from supports A and B of the contact network (Fig. 8.10, a) or transverse cables.

The quality of current collection is largely determined by the sag of the wire, which depends on the resulting load on the wire, which is the sum of the wire's own weight (in case of ice with ice) and the wind load, as well as the span length and tension of the wire. The quality of the current collection is greatly influenced by the angle a (the smaller it is, the worse the quality of the current collection), contact pressure changes significantly, shock loads appear in the reference zone, there is an increased wear of the contact wire and current collector inserts of the current collector. It is possible to slightly improve the current collection in the reference zone by using the suspension of the wire at two points (Fig. 8.10.6), which, under certain conditions, provides reliable current collection at speeds up to 80 km / h. It is possible to noticeably improve the current collection with a simple suspension only by significantly reducing the length of the spans in order to reduce the sag, which in most cases is uneconomical, or by using special wires with significant tension. In this regard, chain suspensions are used (Fig. 8.11), in which the contact wire is suspended from the supporting cable using strings. The suspension, consisting of a supporting cable and a contact wire, is called single; if there is an auxiliary wire between the carrying cable and the contact wire - double. In a chain suspension, the carrier cable and the auxiliary wire are involved in the transmission of traction current, therefore they are connected to the contact wire by electrical connectors or conductive strings.

The main mechanical characteristic of a catenary is considered to be elasticity - the ratio of the height of the overhead wire to the force applied to it and directed vertically upward. The quality of the current collection depends on the nature of the change in elasticity in the span: the more stable it is, the better the current collection. In simple and conventional chain suspensions, the elasticity in the middle of the span is higher than that of the supports. Alignment of elasticity in the span of a single suspension is achieved by installing spring cables 12-20 m long, on which vertical strings are attached, as well as by a rational arrangement of ordinary strings in the middle part of the span. Double pendants have more permanent elasticity, but they are more expensive and more complicated. To obtain a high indicator of the uniformity of the distribution of elasticity in the span, various methods are used to increase it in the area of the support unit (installation of spring shock absorbers and elastic rods, torsion effect from twisting the cable, etc.). In any case, when developing suspensions, it is necessary to take into account their dissipative characteristics, i.e. resistance to external mechanical loads.

The contact suspension is an oscillatory system, therefore, when interacting with pantographs, it can be in a state of resonance caused by the coincidence or multiplicity of the frequencies of its natural oscillations and forced oscillations, determined by the speed of the current collector along the span with a given length. In the event of resonance phenomena, a noticeable deterioration in current collection is possible. The limit for current collection is the speed of propagation of mechanical waves along the suspension. If this speed is exceeded, the pantograph has to interact, as it were, with a rigid, non-deformable system. Depending on the standardized specific tension of the suspension wires, this speed can be 320-340 km / h.

Single and chain hangers consist of separate anchoring sections. Suspension attachments “at the ends of the anchoring sections can be rigid or compensated. On the main railway. are used mainly compensated and semi-compensated suspensions. In semi-compensated suspensions, compensators are available only in the contact wire, in compensated ones - also in the carrying cable. In this case, in the case of a change in the temperature of the wires (due to the passage of currents through them, changes in the ambient temperature), the sag of the carrying cable, and, consequently, the vertical position of the contact wires remain unchanged. Depending on the nature of the change in the elasticity of the suspensions in the span, the sag of the contact wire is taken in the range from 0 to 70 mm. Semi-compensated suspensions are vertically adjusted so that the optimal sag of the contact wire corresponds to the average annual (for a given area) ambient temperature.

The design height of the suspension - the distance between the supporting cable and the overhead wire at the suspension points - is selected based on technical and economic considerations, namely, taking into account the height of the supports, compliance with the current vertical dimensions of approaching buildings, insulation distances, especially in the area of artificial structures, etc.; in addition, the minimum inclination of the strings must be ensured at extreme values of the ambient temperature, when noticeable longitudinal movements of the contact wire relative to the carrying cable can occur. For compensated suspensions, this is possible if the carrying cable and the contact wire are made of different materials.

To increase the service life of the contact inserts of the current collectors, the contact wire is placed in a zigzag plan. Various options for suspension of the carrying cable are possible: in the same vertical planes as the overhead wire (vertical suspension), along the axis of the track (half-slant suspension), with zigzags opposite to the zigzags of the contact wire (oblique suspension). Vertical suspension has less wind resistance, oblique - the greatest, but it is the most difficult to install and maintain. On straight sections of the track, a semi-skew suspension is mainly used, on curved sections - vertical. In areas with especially strong wind loads, a diamond-shaped suspension is widely used, in which two contact wires, suspended from a common bearing cable, are located at supports with opposite zigzags. In the middle parts of the spans, the wires are pulled together by rigid strips. In some suspensions, lateral stability is ensured by using two load-bearing cables, forming a kind of cable-stayed system in the horizontal plane.

Abroad, single chain pendants are mainly used, including in high-speed sections - with spring wires, simple spaced support strings, as well as with load-bearing cables and contact wires with increased tension.

Contact wire

The overhead wire is the most critical element of the overhead catenary, which directly makes contact with the current collectors of the EPS during the current collection process. Typically one or two contact wires are used. Two wires are usually used when picking up currents of more than 1000 A. On domestic railways. e. contact wires with a cross-sectional area of 75, 100, 120, less often 150 mm2 are used; abroad - from 65 to 194 mm2. The cross-sectional shape of the wire has undergone some changes; in the beginning. 20th century the cross-sectional profile has acquired the shape with two longitudinal grooves in the upper part - the head, which serve to fix the overhead catenary on the wire. In domestic practice, the dimensions of the head (Fig. 8.12) are the same for different cross-sectional areas; in other countries, the head dimensions depend on the cross-sectional area. In Russia, the contact wire is marked with letters and numbers indicating the material, profile and cross-sectional area in mm2 (for example, MF-150 - copper shaped, cross-sectional area 150 mm2).

In recent years, low-alloy copper wires with silver and tin additives have become widespread, which increase the wear and heat resistance of the wire. The best indicators for wear resistance (2-2.5 times higher than that of a copper wire) have bronze copper-cadmium wires, but they are more expensive than copper wires, and their electrical resistance is higher. The feasibility of using one or another wire is determined by a technical and economic calculation, taking into account specific operating conditions, in particular when solving issues of ensuring current collection on high-speed lines. Of particular interest is a bimetallic wire (Fig. 8.13), suspended mainly at the receiving and departure tracks of stations, as well as a combined steel-aluminum wire (the contact part is steel, Fig. 8.14).

During operation, the contact wires wear out during current collection. Distinguish between electrical and mechanical components of wear. To prevent wire breakage due to an increase in tensile stresses, the maximum wear value is normalized (for example, for a wire with a cross-sectional area of 100 mm, the allowable wear is 35 mm2); as the wear increases, the wires periodically reduce its tension.

During operation, a break in the contact wire can occur as a result of the thermal effect of an electric current (arc) in the zone of interaction with another device, i.e., as a result of a wire burnout. Most often, overhead wire burns occur in the following cases: over the current collectors of a stationary EPS due to a short circuit in its high-voltage circuits; when raising or lowering the pantograph due to the flow of a load current or short circuit through an electric arc; with an increase in the contact resistance between the wire and the contact inserts of the pantograph; the presence of ice; closing the pantograph runner of the different branches of the insulating coupling of the anchor sections, etc.

The main measures to prevent wire burnout are: increasing the sensitivity and speed of protection against short-circuit currents; the use of a blocking on the EPS that prevents the pantograph from lifting under load and forcibly disconnects it when lowering; equipping the insulating joints of the anchor sections with protective devices that contribute to the extinguishing of the arc in the zone of its possible occurrence; timely measures to prevent ice deposits on wires, etc.

Carrier cable

Carrying cable - a chain suspension wire attached to the supporting devices of the overhead catenary. A contact wire is suspended from the carrying cable with the help of strings - directly or through an auxiliary cable.

On domestic railways. on the main tracks of lines electrified with direct current, mainly copper wire with a cross-sectional area of 120 mm2 is used as a supporting cable, and steel-copper wire (70 and 95 mm2) on the side tracks of stations. Abroad, bronze and steel cables with a cross section of 50 to 210 mm2 are also used on alternating current lines. The tension of the cable in a semi-compensated overhead catenary varies depending on the ambient temperature in the range from 9 to 20 kN, in the compensated suspension, depending on the wire brand, within 10-30 kN.

String

A string is an element of a chain overhead suspension, with the help of which one of its wires (usually a contact one) is suspended from the other - a carrying cable.

By design, there are: link strings made up of two or more ball-and-socket links of rigid wire; flexible strings made of flexible wire or nylon rope; rigid - in the form of spacers between the wires, used much less often; looped - from a wire or metal strip, freely suspended on the upper wire and rigidly or hingedly fixed in the string clamps of the lower (usually contact); sliding strings attached to one of the wires and sliding along the other.

On domestic railways. The most widespread are link strings made of bimetallic steel-copper wire with a diameter of 4 mm. Their disadvantage is electrical and mechanical wear in the joints of the individual links. These strings are not considered conductive in the calculations. Flexible strings of copper or bronze stranded wire, rigidly attached to string clamps and acting as electrical connectors distributed along the catenary and do not form significant concentrated masses on the contact wire, which is typical for typical transverse electrical connectors used for link and other non-conductive strings. Sometimes, non-conductive catenary catenary strings made of nylon rope are used, for which transverse electrical connectors are required.

Sliding strings, capable of moving along one of the wires, are used in semi-compensated chain catenary suspensions with a low design height, when installing sectional insulators, in places of anchorage of the carrying cable on artificial structures with limited vertical dimensions and in other special conditions.

Rigid strings are usually installed only on the overhead points of the contact network, where they act as a limiter for the lifting of the contact wire of one suspension relative to the wire of the other.

Reinforcing wire

Reinforcing wire - a wire electrically connected to the catenary, which serves to reduce the total electrical resistance of the catenary. As a rule, the reinforcing wire is suspended on brackets from the field side of the support, less often over the supports or on consoles near the supporting cable. The reinforcing wire is used in the areas of direct and alternating current. Reducing the inductive resistance of the AC catenary depends not only on the characteristics of the wire itself, but also on its placement relative to the wires of the overhead catenary.

The use of a reinforcing wire is foreseen at the design stage; as a rule, one or more stranded wires of the A-185 type are used.

Electrical connector

Electrical connector - a piece of wire with conductive fittings intended for electrical connection of the wires of the contact network. A distinction is made between transverse, longitudinal and bypass connectors. They are made of bare wires so that they do not interfere with the longitudinal movement of the wires of the contact suspensions.

Cross connectors are installed for parallel connection of all wires of the contact network of the same track (including reinforcing ones) and at stations for catenary hangers of several parallel tracks included in one section. Cross connectors are mounted along the path at distances depending on the type of current and the proportion of the cross-section of the contact wires in the total cross-section of the wires of the contact network, as well as on the operating modes of the EPS on specific traction arms. In addition, at the stations, the connectors are placed in the places of starting and accelerating the EPS.

Longitudinal connectors are installed on the air arrows between all the wires of the contact suspensions that form this arrow, at the mating points of the anchor sections - on both sides with non-insulating mates and on one side with insulating mates and in other places.

Bypass connectors are used in cases where it is required to replenish the interrupted or reduced cross-section of the overhead catenary due to the presence of intermediate anchors of the reinforcing wires or when insulators are included in the carrying cable to pass through an artificial structure.

Contact system fittings

Overhead catenary fittings - clamps and parts for connecting the wires of the overhead catenary with each other, with supporting devices and supports. The armature (Fig. 8.15) is divided into tension (butt, end clamps, etc.), suspension (string clamps, saddles, etc.), fixing (fixing clamps, holders, ears, etc.), conductive, mechanically slightly loaded (clamps supply, connecting and transitional - from copper to aluminum wires). Products that make up the fittings, in accordance with their purpose and production technology (casting, cold and hot stamping, pressing, etc.), are made of ductile iron, steel, copper and aluminum alloys, and plastics. The technical parameters of the fittings are regulated by regulatory documents.

GOST 32679-2014

INTERSTATE STANDARD

RAILWAY CONTACT NETWORK

Technical requirements and control methods

Contact line for railway. Technical requirements and control methods

ISS 29.280

OKP 31 8533

Introduction date 2015-09-01

Foreword

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 "Interstate standardization system. Basic provisions" and GOST 1.2-2009 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for development, adoption, application, renewal and cancellation "

Information about the standard

1 DEVELOPED by Open Joint Stock Company Scientific Research Institute of Railway Transport (JSC VNIIZhT)

2 INTRODUCED by the Interstate Technical Committee for Standardization MTK 524 "Railway Transport"

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Minutes dated June 25, 2014 N 45-2014)

Voted for adoption:

Short name of the country according to MK (ISO 3166) 004-97 | Abbreviated name of the national standardization body |

|

Ministry of Economy of the Republic of Armenia |

||

Belarus | State Standard of the Republic of Belarus |

|

Kyrgyzstan | Kyrgyzstandard |

|

Rosstandart |

||

Tajikistan | Tajikstandart |

|

Ministry of Economic Development of Ukraine |

This standard can be applied on a voluntary basis to comply with the requirements of technical regulations "On the safety of railway infrastructure" and "On the safety of high-speed rail transport"

4 By order of the Federal Agency for Technical Regulation and Metrology dated October 09, 2014 N 1285-st, the interstate standard GOST 32679-2014 was put into effect as a national standard of the Russian Federation from September 1, 2015.

5 INTRODUCED FOR THE FIRST TIME

Information on changes to this standard is published in the annual information index "National Standards", and the text of changes and amendments is published inthe monthly information index "National Standards". In case of revision (replacement) or cancellation of this standard, a corresponding notice will be published in the monthly information index "National Standards". Relevant information, notice and texts are also posted in the public information system -on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet

1 area of use

1 area of use

This standard applies to the railway contact network (hereinafter referred to as the contact network) and establishes the technical requirements and control methods for the 3 kV direct current and 25 kV alternating current overhead catenary systems designed to transmit electricity to electric railway rolling stock moving at speeds of up to 250 km. / h

2 Normative references

This standard uses normative references to the following standards:

GOST 8.207-76 State system for ensuring the uniformity of measurements. Direct measurements with multiple observations. Methods for processing observation results. Basic Provisions

GOST 427-75 Measuring metal rulers. Technical conditions

GOST 2584-86 Contact wires made of copper and its alloys. Technical conditions

GOST 7502-98 Metal measuring tapes. Technical conditions

GOST 9238-2013 Dimensions of railway rolling stock and approaching buildings

GOST 12393-2013 Linear overhead rail fittings. General specifications

GOST 12670-99 Porcelain disc insulators for the contact network of electrified railways. General specifications

GOST 13276-79 Linear fittings. General specifications

GOST 13837-79 General purpose dynamometers. Technical conditions

GOST 16350-80 Climate of the USSR. Zoning and statistical parameters of climatic factors for technical purposes

GOST 17703-72 Electrical switching devices. Basic concepts. Terms and Definitions

GOST 18311-80 Electrical products. Terms and definitions of basic concepts

GOST 23875-88 Electricity quality. Terms and Definitions

GOST 24291-90 Electrical part of the power plant and electrical network. Terms and Definitions

GOST 27744-88 Insulators. Terms and Definitions

GOST 30284-97 * Polymer rod insulators for contact networks of electrified railways. General specifications

________________

* Access to international and foreign documents mentioned in the text can be obtained by contacting the User Support Service. - Note from the manufacturer of the database.

GOST 32623-2014 Compensators for railway overhead catenary. Technical conditions

GOST 32697-2014 Carrier overhead cables. Technical conditions

GOST 32895-2014 Electrification and power supply of railways. Terms and Definitions

Note - When using this standard, it is advisable to check the validity of reference standards in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or according to the annual information index "National Standards", which was published as of January 1 of the current year, and by the editions of the monthly information index "National Standards" for the current year. If the reference standard is replaced (changed), then when using this standard, the replacing (modified) standard should be followed. If the reference standard is canceled without replacement, then the provision in which the reference to it is given applies to the extent not affecting this reference.

3 Terms and definitions

This standard uses the terms according to GOST 17703, GOST 18311, GOST 23875, GOST 24291, GOST 27744, GOST 32895, as well as the following terms with the corresponding definitions:

_______________

In the Russian Federation, instead of the specified standard, GOST R 54130-2010 "The quality of electrical energy. Terms and definitions" is in force.

3.1 transition span (railway catenary): A span of a catenary, on adjacent supports of which there are contact wires of two adjacent anchor sections.

3.2 calculated length of the transition span: The span length obtained as a result of the design calculation.

4 Technical requirements

4.1 General

4.1.1 Parts of the catenary, with the exception of the overhead catenary and its fixing elements, must be located outside the building's approximation dimension in accordance with GOST 9238:

C - for lines with a speed of up to 160 km / h;

C - "" "" "" over 160 to 250 km / h.

4.1.2 The load-bearing capacity of the overhead contact network structures should correspond to the design values given in the national design codes.

_______________

STN TsE 141-99 "Standards for the design of the contact network", approved by the Ministry of Railways of Russia on 26.04.2001.

4.1.3 The climatic region for determining the technical requirements and climatic performance of the overhead contact network devices must be selected in accordance with GOST 16350.

4.2 Design requirements

4.2.1 The height of the suspension of the overhead wire should be limited by the size of the railway rolling stock with the pantograph folded and lowered and by the size of the approaching buildings.

The height of the overhead wire suspension outside artificial structures must be at least:

- on hauls and railway stations - 5750 mm;

- at level crossings - 6000 mm.

The height of the overhead wire suspension within the artificial structures should be, mm, not less than:

- 5550 - for a 3 kV direct current overhead contact network;

- 5570 - for 25 kV AC catenary.

The suspension height of the contact wire should be no more than 6800 mm.

the upper outline of the outline of the approximation of buildings; |

|

a contour corresponding to the positions of the pantograph at its displacements in height and to the sides; |

|

position of the contact wire; |

|

top outline of the rolling stock gauge. |

Figure 1 - Distances between structures, overhead contact devices, pantographs and rolling stock

4.2.2 Distance A from the parts of the current collector and the contact network that are energized to the grounded parts of structures and railway rolling stock (see Figure 1), there must be at least:

- 200 mm - for a contact network at a voltage of 3 kV;

- 270 mm - "" "" "25 kV.

4.2.3 The distance from the axis of any railway track on the tracks to the nearest point of the surface of the contact network support on straight sections of the track and on curves with a radius of more than 3000 m must be at least:

- 3.1 m - for sections of railway lines with a speed of up to 120 km / h;

- 2.75 m - "" "" "in especially difficult conditions at a speed of up to 120 km / h;

- 3.3 m - for sections of railway lines with a speed of over 120 to 250 km / h;

- 5.7 m - in recesses in climatic regions with snow cover for more than 14 days a year in accordance with GOST 16350 and at the exits from them at a length of 100 m for all railway lines.

Deviations during the installation of the contact network supports are allowed only in the direction of increasing the size, but not more than 150 mm from the design position.

In the recesses, the contact network supports should be installed outside the cuvettes on the field side.

On curved sections of a railway track with a radius of up to 3000 m, the indicated distances should be increased by widening the horizontal distance between the axes of the tracks in accordance with GOST 9238 (Table G.5).

4.2.4 The distance from the axis of any railway track at railway stations to the nearest point on the surface of the contact network support must be at least 2.45 m.

4.2.5 The parameters and design of the overhead catenary are selected according to the normative document.

4.3 Requirements for the zigzag contact wire

4.3.1 Overhead wires on a straight section of a railway track and a section with a curve radius of more than 3000 m should be placed in a zigzag manner relative to the track axis with alternating zigzag locations relative to the track axis at adjacent supports. The zigzag should be (300 ± 100) mm, except for the diamond-shaped catenary, where the zigzag should be in the range of 300-400 mm.

On curved sections of the railway track with a radius of up to 3000 m, the zigzag of the overhead wire should be no more than 450 mm, so that the projection of the overhead wire onto the plane of the track in the middle of the span is no more than 400 mm from the axis of the track.

The zigzag of the contact wires of the diamond-shaped catenary must be within 300-400 mm.

4.3.2 The zigzag of the contact wire with a double contact wire refers to the wire external from the axis of the pantograph. In this case, the contact wires at the fixing points should be located at a distance of 40 to 60 mm from each other.

4.3.3 The zigzags of the contact wire shall be arranged so that any three adjacent fixing points are not in a straight line.

4.4 Requirements for the length of the span of the contact network

4.4.1 The span length should be determined as the shortest obtained from the two design modes:

- the highest wind load;

- the greatest ice load with simultaneous wind load.

4.4.2 The length of the span with an average anchorage must be reduced with a compensated suspension by 5%, with a semi-compensated one - by 10% relative to the permissible span length.

4.4.3 The lengths of two adjacent spans should not differ by more than:

- by 25% - for sections of railway lines with a speed of up to 120 km / h;

- by 15% - "" "" "over 120 km / h to 250 km / h.

4.5 Retainer requirements

The design of the retainer should ensure:

- squeezing the contact (s) wire (s) at least 250 mm;

- longitudinal movement of the contact (s) wire (s) not less than 500 mm in both directions from the middle position of the latch.

4.6 Requirements for anchor sections and overhead catenary expansion joints

4.6.1 The length of the anchor section should be, m, not more than:

-1600 - for sections with train speeds up to 120 km / h;

-1400 - "" "" "more than 120 km / h.

When the length of the anchor section is less than 700 m, the overhead catenary compensator, as a rule, must be installed on one side, while the middle anchorage is not used.

4.6.2 The deviation of the tension value of the contact wire and the carrying cable from the design value along the entire length of the anchor section should be no more than ± 5%.

4.6.3 Overhead compensators must comply with the requirements of GOST 32623.

4.7 Requirements for the interfaces of the anchor sections of the contact network

4.7.1 Mates of the anchor sections of the contact network must ensure the mutual longitudinal movement of the wires forming these mates, as well as the smooth transition of the skids of the pantographs from the contact wire of one anchor section to the contact wire of another.

4.7.2 Mates of the anchor sections of the contact network should be performed according to one of the following options:

- with one transition span;

- with two transition spans;

- with three transition spans.

4.7.3 The length of the transition span of the contact network is selected in accordance with 4.4.1.

The length of transition spans of the contact network less than 30 m is not allowed.

4.7.4 The conjugation of the anchor sections of the contact network is recommended to be taken:

- with one transition span with a span length of more than 45 m;

- with two and three transition spans with a span length of less than 45 m.

4.7.5 On non-insulating junctions of anchor sections of the contact network, the distance in the horizontal plane between the inner sides of the contact wires interacting with the pantograph in the transition spans must be at least 100 mm.

The rise of the contact wire outgoing to the anchorage above the working wire in the place where the projection of the inoperative branch of the contact wire going to the anchorage intersects with the inner side of the rail head must be at least 300 mm.

4.7.6 On the insulating junctions of the anchor sections of the contact network with normally connected longitudinal disconnectors, the distance in the horizontal plane between the inner sides of the contact wires interacting with the pantograph in the transition spans should be, mm, not less:

- 500 - for 25 kV AC catenary;

- 400 - "" "" "3 kV.

At insulating junctions of anchor sections of the contact network with normally disconnected longitudinal disconnectors, this distance should be at least 550 mm, regardless of the type of current.

4.7.7 Insulating mates of the anchor sections of the contact network with normally disconnected longitudinal disconnectors, as well as generating neutral inserts, must be equipped with protective devices against overhead wire burnout by an electric arc. On two-way railway tracks, protective devices must be installed in both directions.

4.8 Requirements for overhead point switches

4.8.1 The air arrow of the contact network must ensure the unimpeded movement of the wires of the overhead catenary during their temperature elongation.

4.8.2 The design of the air arrow of the contact network must be made:

- with / without crossing (s) of contact wires, if the railroad switch with the cross brand is up to 1/22;

- without crossing the contact wires with a flatter railroad turnout (cross brand at least 1/22).

4.8.3 The vertical projection of the point of intersection of the contact wires on the overhead switch of the contact network at the level of the rail head of an ordinary turnout switch should be located within the shaded area at a specified distance from the track axes (see Figure 2).

Figure 2 - Location on the plane of the path of an ordinary turnout switch of the projection of the point of intersection of the contact wires of the air arrow

4.8.4 The vertical projection of the point of intersection of the contact wires on the overhead switch of the contact network at the level of the rail head with cross and blind turnouts should be located within the shaded area at a specified distance from the track axes (see Figure 3).

Figure 3 - Location on the plane of the track with cross and blind turnouts of the projection of the point of intersection of the contact wires of the air arrow

4.8.5 The contact wires of the contact network of the main railway tracks or railway tracks of the preferred direction of movement of trains on air switches with an intersection should be located at the bottom.

4.9 Requirements for electrical connections of the overhead line

4.9.1 For the electrical connection of the wires of the contact network, it is necessary to use linear fittings of the contact network that meet the requirements of GOST 12393, and linear fittings that meet the requirements of GOST 13276.

4.9.2 Transverse electrical connectors of the contact network are installed:

- between the wires of the contact network at the points of connection of the disconnector loops;

- on both sides of the overhead switch of the contact network outside the pick-up zone;

- on both sides of the overhead sectional insulator at a distance of no more than one span;

- between the wires of the catenary hangers on non-insulating joints;

- between the contact suspensions of the contact network of the station railway tracks, united into one section;

- in the intermediate spans of the contact network between the supporting cable and the overhead wire, outside the spring cable or supporting string, where it is necessary according to thermal calculations;

- between the wires of the overhead catenary and the reinforcing wires of the contact network at the points of their connection to the supply line of the contact network.

4.9.3 Electrical connectors of the contact network must be made of M95 or M120 wire in accordance with GOST 32697.

4.10 Requirements for supports and anchors of the contact network

In the contact network, support racks, support foundations, anchors should be used that meet the requirements of the national standards of the states given in the preface.

_______________

In the Russian Federation, GOST R 54270-2010 "Racks for the supports of the overhead railroad network. Technical conditions", GOST R 54272-2010 "Foundations for the supports of the overhead railroad network. Technical conditions" and GOST R 54271-2010 "Anchors for the contact network railways. Technical conditions ".

4.11 Requirements for catenary insulators

In the contact network, insulators should be used that meet the requirements of GOST 12670, GOST 30284, as well as insulators of the contact network and sectional insulators that meet the requirements of national standards.

_______________

In the Russian Federation, GOST R 55648-2013 "Insulators for overhead railways. General specifications" and GOST R 55649-2013 "Sectional insulators for overhead railways. General specifications" are used.

4.12 Requirements for overhead wires

In the contact network, wires should be used that meet the requirements of GOST 2584 and GOST 32697.

_______________

In the Russian Federation, GOST R 55647-2013 "Contact wires made of copper and its alloys for electrified railways. Technical conditions" are used.

5 Control methods

5.1 General requirements

The parameters are controlled by the methods indicated in Table 1.

Table 1 - Methods of parameter control