Which is better lithium ion or polymer. Lithium polymer batteries. Types and device. Advantages and disadvantages. Which is better to choose li ion or li polymer

Today, robotic kits are beginning to significantly help in human learning. Recently, one of the leading providers of educational solutions STEAM (the term means learning using science, technology, engineering, art and mathematics as points of interaction for conducting surveys, dialogues with students) debuted on the global arena for innovators and advanced technologies (at the consumer electronics exhibition CES 2020) and creating critical thinking). The debutant was the company Matatalab (Matatalab), attracting attention with a line of robotic kits Matatalab Coding Set and Matatalab Lite - sought to test innovative technologies. Which help develop computational thinking skills and prepare children for the digital world.

Robotics and Education News: The Matatalab Coding Set and Matatalab Lite developmental robotic kits can prepare you to understand the digital world.Matatalab's surprisingly simple robotic kits follow the development of children's cognitive abilities (from concrete to abstract) and use simple character designs so that learning children can understand coding and computational thinking through fun yet challenging play-based quests.

Matatalab itself spans the B2B (business-to-business) and B2C (business-to-consumer) markets, offering professional solutions to educational institutions and families around the world, including programming robots (robot kits), training programs, tutorial packages and so on. Video review of the robotic Matatalab Coding Set: Programming is easy as "ABC".

It is a practical robot for children from 4 to 9 years old. Encourage kids to learn basic coding / programming concepts through adventure and hands-on play! Using coding blocks with a light hand, kids can now learn to program without screens.

For many years of development, Matatalab has adhered to the principle of "Coding and Confidence to Make a Difference", Matatalab said.

Video review of the robotic kit Matatalab Lite:Matatalab Lite is an adorable and easy-to-use robot encoder ready to take young children from the age of three on an exciting coding / programming adventure. It consists of a robotic machine with sensors and a wireless controller with three modes, namely control mode, coding mode and sensor mode.

The robotic set develops problem solving, critical thinking, creativity and collaboration skills for your kids through hands-on game programming. Children can enjoy learning basic programming concepts such as sequencing, conditionals, and debugging, and will be constantly challenged with more challenging problems.

A few words why the training robotic sets Matatalab Coding Set and Matatalab Lite were created from the manufacturer:"The two founders of Matatalab previously worked for an industry-leading educational robotics company, supplying software and hardware for teaching programming to elementary school students around the world. Based on this experience, they identified a lack of programming products for young children on the market. Despite the educational value of STEM, computer science, programming, and computer thinking, learning to program is still limited to programming on tablets or computers. However, the Computer Science Teachers Association (CSTA) standards have shown that children can learn the basics of programming during early childhood education. Therefore, they envisioned creating an easy-to-use robot for teaching programming for children with low thresholds, rich features and diverse application scenarios. They later founded Matatalab Co., Ltd and successively released "Matatalab Pro Set", "Matatalab Coding Set", and "Matatalab Lite". Instead of programming languages, these products use a tangible programming language that matches the cognitive characteristics of children aged 4-9 years. The coding kit is intended for children aged 4 and over. Given that the coding block is a programming language, no screen is required and children can edit their own programs like replacing building blocks. In addition, expansion packs such as music, painting and gauges are also available for children to achieve advanced learning skills. Designed specifically for 3-4 years old, the Lite series is equipped with a controller instead of code boards and blocks. This design is focused on the direction of exploration and consistency of children of this age, and it is beneficial for children to acquire basic sensory perceptions such as sound, light, color, and speed.

- History of the creation of robots, from Matatalab.

One of the founders is a graduate of the mathematics department of China's first Tsinghua University. He designed the entire product portfolio. Initially, a technical prototype was developed and demos built on Raspberry Pi boards. All of this has been verified by relevant teachers, students and parents in several communities and educational institutions. After validating the concept, it was presented to industry experts in different countries and discussed further optimization. Then the first round of investments took place. The team started to expand and the product design became more attractive. After a year of research and development, the product experience has improved significantly. Subsequently, 3D printing samples were tested in 13 countries and received feedback from many education experts, teachers and students in Europe and the United States. This helped to further improve product quality and ultimately achieve mass production. It is noted that safety and reliability are top priorities because the product is designed for children. Professional organizations and suppliers were found to solve supply chain and mass production problems, and the products were thoroughly tested to even pass food quality certification. Now it is the highest level of testing of toy products in the world, and according to the creators, the products can be as safe as baby bottles.

- Interesting moments that arose when creating robots, according to Matatalab.

When we visited investors to look for investments, the demo prototype was damaged during the trip. Thus, we could only play the role of a robot through gestures and body language to explain our practical coding concepts and how robots work. Fortunately, we have impressed investors and received investment. Of course, we believe that this is because our product is exceptional and that we are the pioneers of the blue ocean market, ”said Rishon Su, CEO of Matatalab.

The design principle of our product is low threshold and high ceiling. It's easy to get started, but the difficulty will increase step by step, constantly testing students' thinking abilities. We have developed three task guides. Many adults found them easy at first, but got lost in high-level tasks or spent a lot of time doing them. For example, a computer science teacher at the University of Chicago could only complete the last stage of our assignment in 6 minutes and 42 seconds. He joked that he would never tell his daughter about this experience. Therefore, while the game is very easy to learn, it is as difficult as an adult game, "said Tony Zheng, chief operating officer of Matatalab."

Matatalab in educational institutions in Russia.

According to the creators of the Matatalab robotic training kits:“Today Matatalab is used in 500-700 educational institutions of various levels from kindergarten to high school. The question of the number of institutions is very difficult because Digis does not work with end users and Matatalab has more than 120 active partners in all regions of the country.

In addition to public schools and kindergartens, Matatalab is used in private development centers as well as teacher development centers in many regions of the country.

In April 2020, the first interschool Matata competition may be held at a Moscow school. Eight kits have already been provided for developing assignments and preparing teams.

At about the same time (in March), the NTI 2020 Olympics will be held in the Siberian region of Russia, in the city of Novosibirsk, together with the Ministry of Education of the Novosibirsk Region. "

The Annual Amusement Parks and Attractions Exhibition (TAAPE) is due to be held in September, from the 9th to the 11th. TAAPE 2020 is the first and only professional entertainment show in Thailand (according to the organizers). The exhibition in Bangkok will showcase the latest achievements in the entertainment and leisure industry. The exhibitors will be both manufacturers producing children's products for the home and mechanical goods, as well as products for the theme park. From more than two dozen countries around the world, it is planned to attract companies and professional visitors. Participants from Russia, Malaysia, Thailand, Singapore, Laos, Cambodia, Indonesia, Vietnam, Burma, China, Korea, India, Taiwan, the Netherlands, Spain, Great Britain and other countries are expected. A good opportunity for foreign companies and distributors to promote their brand.

Exhibitions & Technology News: The officially named Thailand Amusement & Attraction Parks Expo or TAAPE is preparing to welcome exhibitors from 20 countries.According to the organizers of TAAPE, this is the first exhibition dedicated to the theme parks, video games and entertainment products industry, which will serve as a showcase for the production and design of an entertainment and theme park company to enter the Southeast Asian market. There is a chance to meet potential business partners, trade buyers, investors and clients. The exhibition will cover the entire ASEAN area, serving as the most efficient trade channel for exhibitors' goods.

It is expected to present 620 booths to the public, exhibitors will come from more than two dozen countries or regions, including Russia, Thailand, Vietnam, Korea, China, Japan, Singapore, Germany, India, France, Malaysia, Australia, America, Indonesia, Taiwan and others.

Themes of the TAAPE exhibition and exhibits:

Video game products and accessories.Game machine, simulator, remote control equipment, various game machines, arcade, home game machine and peripherals, animation product, online game, carnival lottery, interactive game machine, doll machine, gift machine, camera with stickers, various coin dispensers , game tokens, game console displays, video game software, puzzle and entertainment equipment.

Park and playground.Robots, roller coasters, skates, ferris wheel, carousel, go-kart, observation car, tour bus, cable car, simulated golf, simulated shooting system, drifting equipment, waterslide, ball for walking on water, sensory boat, water fountain, system cold fog, water purification equipment, wave making equipment, extreme sports equipment, outdoor sports, climbing equipment, optoelectronic combined entertainment equipment, laser, lighting, pyrotechnics, special effects, motion pictures, 3D and 4D film , cinema equipment for water screens, executive equipment, special photographic equipment, special stereoscopic cinema projector, software for controlling vending machine, playground and entertainment center, ticketing system, kiosk, park lighting, outdoor landscape lighting, LED displays, LED lamps, parks sculpted sculpture and so on.

Children's entertainment facilities.Baby cart, electric car, swing, preschool, inflatable attractions, air models, children's play frame, slide, swing, turntable, naughty castle, trampoline, entertainment combo toy, safety pillow and other equipment.

Landscaping.Park, scenic spot, landscape, tourism project planning, design and engineering, landscape sketch design, entertainment project design, leisure and entertainment product packaging.

The exhibition also plans to touch upon topics for objects of visit.

Various theme parks, water parks, scenic spots, film and television bases, resorts, leisure clubs, supermarkets, hotels;

Museums, science and technology museums, exhibition halls, ocean halls, preparation and maintenance of memorial buildings, property management.

Who might be interested in TAAPE 2020:Developers of various theme and industrial parks;

Government planning and design departments, and related procurement departments;

Various cultural tourism organizers and commercial real estate investors;

Distributors of goods for entertainment and video games, owners of gaming halls;

Relevant education departments, schools, vocational schools;

Sporting goods sellers, entertainment investors and other professionals;

Financial, insurance and venture investment institutions;

Other professionals related to the theme park and cultural tourism;

Game developers, operators, publishers, software and hardware vendors, research institutes, gamers, and so on.

Exhibition opportunity.Visitors to the new amusement parks and attractions trade show will have the opportunity to shake hands with industry experts, decision makers and clients to discuss challenges and solutions.

The organizers of one of the major exhibition shows, "Asia Amusement & Attractions Expo", are going to hold it in May 2020 (from the tenth to the twelfth). At the exhibition dedicated to entertainment and attractions, planning to adhere to the main topics: high-tech equipment, games and devices for them, theme parks and attractions, inflatable equipment, water technology, children's entertainment. The organizers also plan to hold special events: a forum on the development of a theme park, an advanced seminar on the operation of indoor parks, a conference on the development of culture and tourism. The venue for the new exhibition should be a Chinese import-export fair complex. Geographically, it is located in the city of Guangzhou, which is located in China.

News from the world of exhibitions and technology: Officially called "2020 Asia Amusement & Attractions Expo" or "AAA 2020" plans to bring together exhibitors from all over the world.Over the past fifteen years, this exhibition has attracted trade visitors from more than fifty countries and regions. According to the organizers, many well-known exhibitors around the world are ready to participate in the new AAA 2020 exhibition, including Chinese exhibitors such as G-Look, UNIS, Golden Horse, Wahlap, Letian, Golden Dragon, Prodigy, Wangming, and foreign brands. such as Sacoa (Argentina), Embed (Australia), Semnox (India), F2 Systems Inc (Korea), Zone Laser Tag & Hologate (Germany), Wibit Sports (Germany), Delta Strike (New Zealand), Dragonautics (Singapore) , as well as others.

What topics fall under the "AAA 2020" exhibition:High-tech equipment (Hi-Tech).

Virtual and augmented reality (VR and AR), 3D modeling, animatronics, systems for snow and ice, Laser tag (laser combat with automatic blasters), special effects and so on;

Games and devices.Arcade and video games, vending machines, play equipment, play sets and so on;

Theme parks and attractions.Photographic solutions, equipment for moving people, security equipment, theater equipment and materials, travel, architecture and design, reception equipment, clothing and so on;

Water technologies.Equipment and materials related to water, design and consulting in water parks and so on;

Playgrounds, trampoline, inflatable boats, gifts and plush toys, children's attractions and so on.

In addition, the organizing committee "AAA" additionally continues to visit major countries of the world (Russia, India, USA, UK, Japan, Korea, Dubai, Turkey, Singapore, Philippines, Vietnam, Indonesia and others) to contact professionals from the entertainment industry and attractions.

The previous exhibition "AAA 2019" broke records.Covering 120,000 square meters of exhibition space, the 15th AAA exhibition broke a record of 90,679 visits. Also, 1,100 exhibitors showcased their latest products and services. A new focus has been set up, the IP Licensing Pavilion, reflecting the new Culture + Tourism trend. According to the survey, 96% of exhibitors received promising results, and 94% of buyers found their products interesting.

Want to know about an incredibly good performing router? There is an Archer AX50 device - this is the latest wireless router from the Chinese company TP-Link Technologies. Unlike conventional routers produced by TP-Link, this model is equipped with the latest Wi-Fi technology, which promises to improve Wi-Fi connections at lightning speed - thanks to the introduction of the sixth generation IEEE 802.11ax wireless standard.

News about routers today: The new model of TP-Link Archer AX50 router supports Wi-Fi 6, up to 3 Gigabits per second, 4K streaming, 40+ device connectivity, saves batteries, has antivirus.The innovative design of the TP-Link Archer AX50 router has a classic rectangular shape with a lot of ventilation holes to cool the device. The model has four external non-removable antennas and several LED indicators to display the status of the router.

Which Wi-Fi router is better?

The new TP-Link Archer AX50 router has been introduced by the Chinese brand as an Intel-based device that offers users access to the latest connectivity in a turnkey system. It supports the latest 802.1ax wireless standard, also known as WiFi 6, to improve overall speed and performance to prepare users for the future when upgrading existing home networking solutions.

The latest version of Wi-Fi 6 wireless technology promises to make WiFi connections much faster than 802.11ac. High performance wireless (Wi-Fi 6) is now available on select mobile phones such as the Samsung Galaxy S10 and Apple iPhone 11.

Many routers with Wi-Fi 6 are extremely expensive at this point, it is possible that the TP-Link Archer AX50 variant is designed to accommodate the widespread use of Wi-Fi 6.

TP-Link Archer AX50 video review: Quick setup and how the new router model with Wi-Fi 6 worksAdditionally, consider what a router can do:

Wi-Fi 6 with Intel Technology delivers three times faster speeds, more capacity, and lower latency than the previous generation of Wi-Fi 5, while an Intel dual-core processor keeps you running smoothly;

Next-generation (data) speeds, up to 3Gbps (2402Mbps in 5GHz and 574Mbps in 2.4GHz) for faster 4K video streaming, video chats and online gaming

The use of "revolutionary" technologies MU-MIMO and OFDMA allows you to connect more than 40 devices.

Protection with TP-Link HomeCare antivirus, which has parental controls;

Target Wake Time technology reduces power consumption of devices, which increases their battery life;

Easy router setup with the powerful TP-Link Tether app in minutes;

There is backward compatibility, the Archer AX50 router model supports all previous 802.11 standards and many devices with Wi-Fi;

A comment about the router from the manufacturer (TP-Link Russia press service):

"Archer AX50 is part of the "Archer AX" line of routers with support for Wi-Fi 6 - a new generation of wireless communication (it also includes models Archer AX11000, AX6000, AX3000, AX10, AX1500 and some others). TP-Link is the world leader in the supply of home wireless devices, so, of course, the company is guided by global trends and innovations taking place in this market.One of these innovations was the presentation by Intel of chipsets with Wi-Fi 6 at the end of 2018 - and already in February 2019, TP-Link showed the first models with Wi-Fi 6 at the MWC 2019 in Barcelona. Archer AX50 just became the first example of cooperation between TP-Link and Intel (in addition to cooperation with Intel, various TP-Link devices are also supplied on chipsets from Qualcomm, Broadcom, Mediatek, and so on ... Google in the production of the Google OnHub router).

The reason why routers with Wi-Fi 6 began to appear was the increased demand for even faster Internet connection speeds, as well as higher bandwidth within the network. All this, in turn, is due to the growing number of wireless gadgets in modern households: today not only laptops and mobile phones are connected to Wi-Fi, but also televisions (television broadcasting is also gradually going "online"), smart home infrastructure devices, game consoles and multimedia devices, including those using augmented and virtual reality. In other words, if you do not take into account the mobile Internet, then Wi-Fi is becoming the main medium for transmitting information, and this environment requires improvements over time.

The Archer AX50 model is just designed for modern households that need a strong foundation to connect to the Internet and connect a large number of clients - with a backlog for several years to come.

Speaking about further market prospects, the following can be noted:

The number of clients that can be connected to Wi-Fi 6 infrastructure will grow;

There will be a growing number of technologies that will leverage Wi-Fi 6 speeds;

The smart home infrastructure will develop, and it will increasingly rely on Wi-Fi;

TP-Link, in turn, will present models on the international and Russian markets that meet the requirements of modern users.

We have large manufacturing facilities as well as several R&D centers in Asia and the United States - allowing us to quickly adapt these requirements into new products and developments. "

Final words:

Recently, the new TP-Link Archer range of routers meet the growing need for better connectivity solutions as consumers continue to integrate smarter devices into their homes that require growing bandwidth.

The new aircraft, called the Flying Gondola, optimizes flight performance through center of gravity control technology. Reliability that allows people to move safely is integral to air mobility. However, in order to widely use the aircraft "Flying Gondola" ("Flying Gondola") as a means of transportation in the air, its creators from Aeronext Inc (Japan) believe that the key aspects are the achievement of both "safety" and " comfort ". So that every passenger can easily use the aircraft without any reason for doubt.

Latest aircraft news: Japanese developer Aeronext has unveiled the "Flying Gondola" for easy air travel.According to the developer Aeronext, the new concept of mobility in the air "Flying Gondola" not only provides "safety" but also "comfort", which differ from the traditional concept of air mobility, which mainly focuses only on the convenience of passengers.

When will the Flying Gondola replace conventional aircraft?

The Flying Gondola provides a new flight experience that Aeronext says allows the passenger to enjoy the freedom and freedom of flight, the scenery in the sky, according to Aeronext. Development goes forward and the next project "Next Mobility" will be the first principal prototype of "Flying Gondola", but more on that later in the review.

The aircraft's vertical takeoff and landing is controlled by a center of gravity technology called "Tiltbody".

The technology that forms an integral part of the new Flying Gondola concept is the recently announced Tiltbody technology (meaning the collective term for Aeronext's center of gravity control technology).

The developed technology stabilizes the takeoff and landing of VTOL aircraft (the term stands for vertical takeoff and landing). During the transition from takeoff to level flight, unlike traditional aircraft where the rotor is fixed, the movable rotor arm (called the "propeller arm") moves to achieve optimal flight performance while keeping the cockpit level relative to ground level. Perhaps this could mean that comfort and safety are maximized.

Also, the company is developing the first principal prototype of the Next Mobility single-seat passenger aircraft. It is a prototype that embodies a new concept of air mobility like the Flying Gondola. It features 4D GRAVITY center of gravity technology and the newly announced VTOL Tiltbody center of gravity technology. The all-new Next Mobility is the first prototype to be a 1/3 the size of a single-seat aircraft.

Aeronext Flight Video Review: Next Mobility prototype embodies the Flying Gondola concept.In the future, Japanese developer Aeronext promises to announce similar aircraft that can be used by multiple people.

A comment on how the Flying Gondola drone was created from the creators:

Natsuko Ito, Global Marketing Director, Aeronext Inc .:

"Aeronext is a technology startup for UAV architecture founded in Japan in 2017 and we have invented the unique 4D GRAVITY® center of gravity control technology that significantly improves stability.

We have already announced several concept models for specific industrial applications using 4D GRAVITY®, such as shipping and inspection applications.

And this time, to better demonstrate the effectiveness of 4D GRAVITY®, we created the concept of the Flying Gondola mobile airplane, equipped with 4D GRAVITY® and other patented technologies that provide both safety and comfort.

We believe this is a realistic solution that will increase the social acceptability of air mobility by providing people with a new flight experience.

We used a unique "split architecture" with our patented 4D GRAVITY® technology, which separates the section of the cabin and the flying section so that the cabin always remains level with the ground.

The original idea for the 4D GRAVITY® was invented by our CTO, Mr. Suzuki, and this Flying Gondola concept model was created by him and his engineering team. "

Technical characteristics of the Aeronext flying machine and the advantages declared by the developer:

A vehicle with remote controlled automatic navigation that does not require a pilot on board;

Smooth and stable transition from takeoff to level flight;

Comfortable fit in the machine because the seat is flush with the ground.

The passenger can relax and enjoy the conversation on the mobile phone;

It is easy to get into the aircraft even in a skirt or high heels;

Front, left and right sides of the aircraft are covered with glass to enjoy the view of flight;

The aircraft is equipped with special wings and a propeller system to prevent collisions even in an emergency landing.

Operating System News and Rumors: Which Apple Device Models Will Upgrade to iOS 14 and When Will the Upgrade Begin? Read on.If you've been tracking updates from the Apple team for iOS, then it should come as no surprise that with every new update Apple compiles an iPhone compatibility list. For example, while iOS 11 and iOS 12 were released for the iPhone prior to the iPhone 5S version. This particular phone was an exception to the iOS 13 release compatibility list.

As you know, Apple periodically disables support for older devices in its updates. The supposed reason for the change in the compatibility list is the processor architecture of the device. That said, it looks like that might not be the case this year when iOS 14 comes out. According to the French source "iPhone Soft", Apple's new iOS 14 system (still in development) could work on all those iPhones. which are currently supported by iOS 13. Supposedly, this is information from a "developer friend at Apple".

Naturally, the list can be replenished with iPhone models of the current year (12 and SE 2). So, it is rumored that if this is true, when the iOS 14 update comes out, it will be available for all iPhone models following the list below:

IPhone 12 Pro Max (rumored only)

- iPhone 12 Pro (rumored);

- iPhone 12 (rumors);

- iPhone SE 2 or known as iPhone 9 (still on hearing);

- iPhone 11 Pro Max;

- iPhone 11 Pro;

- iPhone 11;

- iPhone Xs Max;

- iPhone Xs;

- iPhone X;

- iPhone XR;

- iPhone 8 Plus;

- iPhone 8;

- iPhone 7 Plus;

- iPhone 7;

- iPhone 6s Plus;

- iPhone 6s;

- And the iPhone SE model.

There is a rather long list of Apple phone models for the new OS than ever before. In addition, if so, the update could also affect the 7th generation iPod Touch media player.

However, the same cannot be said for tablet computers. The report added that the debut in a couple of months, again according to rumors, the iPadOS 14 system may bypass the iPad Air 2 and iPad mini 4 (that is, support for tablets with Apple A8X and A8 chips will be discontinued). For iPadOS 14, users are left with the following list:

9.7-inch iPad Pro

- 10.5-inch iPad Pro;

- 11-inch iPad Pro;

12.9-inch iPad Pro

- iPad Air 3rd generation;

- iPad 5th generation;

- iPad 6th generation;

- iPad 7th generation;

- And the 5th generation iPad Mini model.

The list may be replenished, according to rumors, the forthcoming version of the tablet "iPad Pro 5G".

In 2019, with the release of iOS 13, the iPhone 5s, popular in Russia, "found itself without support." The smartphone has received six major updates to the mobile operating system in its life.

Considering that the iPhone SE, iPhone 6S Plus, and iPhone 6S were the last iPhones with headphone jacks, many Apple smartphone users preferred to hold onto their older iPhones for as long as possible. So if you're still using a 2015 iPhone, you may be able to breathe. A new rumor claims that iOS 14 will be compatible with the original iPhone 6S and iPhone SE.

New iOS 14 features and secrets:

What will iOS 14 be like?

As for the functionality of the new system, there is absolutely no information about what can be expected from iOS 14. IT Corporation Apple, like every year, is likely to unveil a new version of iOS at its annual WWDC (Worldwide Developers Conference), which will be held in the United States around June 2020. The latest version of iPadOS is also making its debut at the event.

On this day, not only the announcement of the main changes is expected, but also the release date for iOS 14 for download to developers (for beta testing), and the release date for download for regular users.

We will definitely write a review of what new will be added to the system, what are the advantages of iOS 14 over version 13. Is it worth updating, about the end of support and possibly device problems after the update.

Summary of iOS 14:Apple has an incentive to maintain support for as many iPhones and iPads as possible for the new version of iOS 14. To increase the chances of engaging users with the latest features of subscription services such as Apple Arcade and Apple TV +.

But since this is the first time we hear about iOS 14 in 2020, the information should be taken with the understanding that these are rumors. After all, details from leaks and rumors are sometimes misunderstood. We can all be convinced of the reality of the forecasts only after Apple itself presents a new version of the operating system at the end of this year.

Soon, we will discuss the burning secrets of iOS 14 (characteristics, functions, is it possible to jailbreak, whether an error occurs during the update, how much the system takes up gigabytes in the phone). We expect good news for older devices.

News about the most beautiful computer cases: The innovative AZZA Pyramid 804 model was created as a glass pyramid transforming into a table.The mesmerizing Pyramid 804 computer case from AZZA is intended not only to demonstrate one assembly of powerful hardware. It is capable of supporting most assemblies that will fit in any common B-pillar chassis. For example, it supports an EATX motherboard, a 300mm graphics card, two 2.5 '' SSD bays, one 3.5 '' HDD bay (the bay is also compatible with a 2.5 '' SSD inches) and also supports water cooling up to 360 mm in length or 120 mm fans in the amount of three, at the bottom of the case. In other words, you can change the hardware as needed or as desired by the computer user.

It was mentioned above that the cool computer case is equipped with a built-in 120mm digital RGB fan Hurricane II, which thanks to its futuristic backlight will be a cool "highlight". But, this is not all the pleasant aesthetics for the user.

Multifunctionality of the computer case

A definite plus is that the unusual Pyramid 804 computer case can be demonstrated to others in more than one way. In addition to the usual bottom-surface mounting like pyramids, the manufacturer also offers an optional four-legged stand that allows the computer case to be mounted upside down (upside down). The bottom of the computer case then becomes a flat surface, allowing the case to be practically used as a glass table.

Regardless of what you do with this unusual computer case, it will prove to be functional and pleasing to the eye in any circumstance.

Video review of the computer case AZZA Pyramid 804 with an elegant pyramidal design:Physical dimensions of the body-pyramid AZZA: Height 585 mm, width and length of the base 490 mm.

The new consumer electronics show CES 2020 (in Las Vegas, America) presented a huge collection of amazing robots designed to perform almost any task, from everyday worries to educating the good in a person. Perhaps as a reflection of our increasingly stressful lifestyles, this year's tech show was also filled with an amazing number of robots designed to provide companionship and alleviate feelings of loneliness.

Without normal battery life, all meaning in a mobile device is lost. The user is tied to the power grid and cannot be connected while moving. At Magazin-Detaley.RU you can buy a lithium-polymer battery and solve problems with a quick discharge of the device.

How to order a lithium polymer battery at Magazin-Detaley.RU

Do you want to quickly buy Li-Pol batteries and not wait for spare parts to be delivered? Please contact our store. We are the suppliers of leading service centers and parts stores, and we are preferred by retail buyers from all over the country.

Our company has been engaged in sales for several years and cooperates directly with equipment manufacturers. We specialize in the supply of high quality original spare parts. This guarantees the customer the uninterrupted operation of the battery.

Also here you will find Li-Ion batteries for laptops, smartphones, phones and tablets.

Our company strives to simplify the ordering procedure as much as possible. To buy a polymer lithium-ion battery, a client does not need to waste time and come to our office. All questions will be quickly resolved through the website, email or phone.

You can find out the exact cost of parts on our website. Store managers are constantly updating the assortment, information on cost and balances.

The Magazin-Detaley.RU company cooperates with legal entities and individuals. You can pay for your order through popular services and payment systems without leaving your home.

The delivery of lithium polymer batteries for smartphones is made through courier services, transport companies or the Russian Post. You can also pick up the goods at a convenient time yourself from our warehouse.

27.10.2018

In the production of energy storage devices, outdated technologies are rapidly being replaced by new solutions. In the beginning, NiCd batteries were superseded by NiMH cells. Instead, they created more advanced generations of storage batteries - Li-ion, LiFePO4, Li-Pol. In this article, we will consider the differences between Li-ion and lithium-polymer batteries, their advantages and preferences for choice, taking into account the peculiarities of the upcoming use of the battery.

Features of Li-ion technology

Lithium batteries began to be mass-produced in the early 1990s. At the initial stage, the functions of the active electrolyte were performed by cobalt and manganese. Now Li-ion storage devices use lithium cobaltate, lithium manganese spinel, lithium ferrophosphate and other compounds as the cathode material. But the key role is played not by the type of substance, but by the peculiarities of its location in the block.

In them, the electrodes (cathode base on aluminum foil and copper anode) are separated by a porous separator, which is impregnated with electrolyte. The cathode and anode in the block are connected by current-collecting terminals. The charge is serviced by positively charged Li ions. They easily pass into the crystal lattices of various substances, create bonds, initiate the course of reactions and cause the release of energy. The principle of operation of Li-ion energy storage devices is similar to full format gel batteries.

The main pros and cons of Li-ion batteries are listed in the table:

|

Advantages |

disadvantages |

|

Small self-discharge - in the 1st month up to 6%, in the following - weaker. The protective circuit consumes about 3% of the accumulated energy per month. |

The need for an integrated protection board. It limits the maximum voltage during charging and does not allow it to drop critically during discharge, limits the current limit and controls the temperature. |

|

High energy density and discharge currents. |

Aging susceptibility, even without exploitation. |

|

High cell voltage compared to NiCd and NiMH cells - 3.6 V. |

A significant drop in capacity in the cold. |

|

No memory effect and easy maintenance. |

Relatively high cost (compared to NiCd batteries). |

|

Long service life. |

|

|

Small size, light weight. |

|

|

No maintenance requirements (except for recharging). |

The technology for creating Li-ion batteries is improving every year, leading to an increase in the safety of their operation and a decrease in cost.

What is the difference from Li-ion Li-Pol technology?

The improvement of Li-ion batteries was aimed at improving the safety of their use and making the technology cheaper. It was possible to solve this problem by changing the electrolyte - instead of a porous separator impregnated from an electrolyte, they began to use a polymer electrolyte. Previously, it was used as a plastic film for conducting current. In Li-pol energy storage devices, the thickness of the element starts from 1 mm, which makes it possible to obtain products of all kinds of shapes and sizes.

But the fundamental answer to the question, what is the difference between Li-Pol batteries and Li-ion models, is the non-use of electrolyte in a liquid state and minimizing the risk of ignition. Lithium polymer batteries have no liquid or gel electrolytes. The active substance is a solid plate and in the area of contact with lithium does not allow the formation of dendrites during cycling. This eliminates the risk of explosions and fires in lithium polymer batteries.

Initially, Li-Pol current sources had weak conductivity and were not suitable for portable devices. But this disadvantage was eliminated by using a gel-like electrolyte. Advanced Li-polymer energy storage devices have an electrolyte membrane. For its manufacture, a separator made of propylene or porous polyethylene, which contains a polymer, is used. Interacting with the electrolyte liquid, it becomes gelatinous.

Advantages and disadvantages of Li-Pol current sources

An important advantage of lithium polymer batteries is their excellent capacity to weight ratio. Due to this quality, Li-Pol power sources are widely used in equipping quadrocopters and other radio-controlled models, in mobile phones and digital technology. The key pros and cons of Li-polymer batteries are shown in the table:

|

Advantages |

disadvantages |

|

Light weight combined with high capacity. |

Relatively high cost. |

|

The ability to create a battery of arbitrary dimensions and shapes, including very thin ones. |

The need for a special recharging mode. |

|

Fast charging. |

The need for balancing the cells. |

|

Lack of memory effect. |

Sensitive to deep discharge, overcharge, low temperatures. |

|

Low wear. |

|

|

High degree of reliability and safe operation. |

|

|

Small self-discharge - up to 5% per month. |

|

|

Unpretentious maintenance. |

|

|

Less wear and tear and self-discharge. |

Which is better, Li-polymer or Li-ion battery?

The answer to this question depends on where and under what conditions the selected current source will be used. The main characteristics of Li-ion and Li-Pol batteries are similar. Different geometric parameters and technical characteristics are collected from Li-ion cells. It is permissible to use them in the range from -20 to +60 ° С, but at borderline temperatures, faster aging occurs.

Li-Pol batteries are produced in all possible geometries, are characterized by significant energy density and are extremely safe. They are most in demand when a compact and reliable power source is required. The operating temperature range of currently produced Li-Pol batteries is identical to the temperature range of Li-ion.

Comparison table of Li-ion and Li-Pol batteries

To find out, taking into account individual priorities, which is better, a Li-polymer or a lithium-ion battery, you need to compare their characteristics. It's easy to do with a comparison table:

|

Characteristic |

Li-ion batteries |

Li-Pol batteries |

|

The number of cycles |

||

|

Selection of standard sizes |

Narrow, there are models in the form of a cylinder and a prism, the most popular cylindrical size is 18650. |

Wide, without standard frames for the format of batteries, it is possible to create cells with a thickness of 1 mm or more. |

|

A bit more |

Lightweight - through the use of a gelled electrolyte and the reduction of metal elements. |

|

|

Capacity with identical dimensions |

Higher, almost doubled. |

|

|

Energy density per unit mass |

From 100 to 190 Wh / kg, depending on the cathode material. |

130 to 200 Wh / kg. |

|

Service life |

Approximately the same: for lithium-ion - from 500 to 2000 charge-discharge cycles, depending on the cathode material, for lithium-polymer - 800 - 1000 cycles. |

|

|

Risk of explosion or fire |

It is present, but the use of the protection board eliminates this risk. |

Minimized - due to the absence of electrolyte leakage and the use of integrated overcharge protection. |

|

Allowable temperatures |

From -20 to +60 ° С, optimally - from 0 to +30 ° С. |

|

|

Duration of charging |

||

|

Voltage (nominal) |

||

|

Discharge limit voltage |

||

|

Optimal and peak load current |

<1С и ˃2С, где С – значение емкости. |

|

|

Charge Features |

With a current of 0.1 ... 1C until reaching 4.1 ... 4.2 V, and then at a constant voltage. |

|

|

Wear rate (natural aging) |

About 0.1% per month. |

Below, 20% in 2 years. |

|

Voltage surges during discharge |

||

According to this table, it is easy to compare, the better, and in what parameters they are inferior to lithium-polymer analogs.

Summing up

Lithium-ion power supplies are widely used in various fields. They are used to equip digital electronics, personal electric vehicles, robots, cordless tools, wheelchairs, and a host of other devices. They have standardized sizes, are easily matched to the required parameters and are well known to consumers. Powerful batteries are successfully used for devices requiring high short-term current consumption.

Lithium-polymer energy storage devices allow you to obtain the required capacity with a smaller size and mass of the power source, therefore, they are in demand in portable devices, quadcopters, toys, and airsoft guns. The main differences between Li-polymer batteries are their higher price, greater variability of shapes and fewer internal loads.

In practice, both types of batteries have similar characteristics, so the selection preferences depend mainly on the area of use. In addition to the type of battery and the cathode substance, the quality of the raw materials used and the production technology affect the characteristics of the current source.

We bring to your attention informative material about.

The growing consumer interest in mobile gadgets and high-tech portable technology in general forces manufacturers to improve their products in various directions. At the same time, there are a number of general parameters, the work on which is carried out in the same way. These include the method of energy supply. Just a few years ago, active market participants could observe the process of displacement by more advanced elements of NiMH origin. Today, new generations of batteries are competing with each other. The widespread lithium-ion technology is successfully replacing the lithium-polymer battery in some segments. The difference from the ionic in the new unit is not so noticeable for an ordinary user, but in some aspects it is significant. At the same time, as in the case of competition between NiCd and NiMH elements, the replacement technology is far from flawless and in some respects is inferior to its analogue.

Li-ion battery device

The first models of serial lithium batteries began to appear in the early 1990s. However, cobalt and manganese were then used as the active electrolyte. In modern ones, it is not so much the substance that is important as the configuration of its placement in the block. Such batteries consist of electrodes that are separated by a pore separator. The mass of the separator, in turn, is just impregnated with the electrolyte. As for the electrodes, they are represented by a cathode base on an aluminum foil and a copper anode. Inside the block, they are interconnected by current collector terminals. Servicing charge performs a positive charge on the lithium ion. This material is advantageous in that it has the ability to easily penetrate the crystal lattices of other substances, forming chemical bonds. However, the positive qualities of such batteries are increasingly not enough for modern tasks, which led to the appearance of Li-pol cells, which have many features. In general, it is worth noting the similarity of lithium-ion power supplies with full-size helium batteries for cars. In both cases, batteries are designed with physical usability in mind. In part, this direction of development was continued by polymer elements.

Lithium polymer battery device

The impetus for improving lithium batteries was the need to combat two disadvantages of existing Li-ion batteries. Firstly, they are unsafe to operate, and secondly, they are quite expensive in terms of price. The technologists decided to get rid of these disadvantages by changing the electrolyte. As a result, the impregnated porous separator was replaced by a polymer electrolyte. It should be noted that the polymer has previously been used for electrical purposes as a plastic film that conducts current. In a modern battery, the thickness of the Li-pol cell reaches 1 mm, which also removes restrictions on the use of various shapes and sizes from developers. But the main thing is that there is no liquid electrolyte, which eliminates the risk of ignition. Now it's worth taking a closer look at the differences from lithium-ion cells.

What is the main difference from an ionic battery?

The fundamental difference lies in the rejection of helium and liquid electrolytes. For a more complete understanding of this difference, it is worth referring to modern car battery models. The need to replace the liquid electrolyte was driven, again, by safety concerns. But if in the case of car batteries, progress stopped at the same porous electrolytes with impregnation, then lithium models received a full-fledged solid base. What is so good about a solid-state lithium polymer battery? The difference from the ionic one is that the active substance in the form of a plate in the contact zone with lithium prevents the formation of dendrites during cycling. This factor excludes the possibility of explosions and fires of such batteries. This is only about the merits, but there are also weaknesses in the new batteries.

Lithium polymer battery life

On average, such batteries can withstand about 800-900 charging cycles. This indicator is modest against the background of modern analogues, but even this factor cannot be considered as a determining element resource. The fact is that such batteries are subject to intense aging, regardless of the nature of their operation. That is, even if the battery is not used at all, its resource will be reduced. And it doesn't matter if it's a lithium-ion battery or a lithium-polymer cell. All lithium-based power supplies are characterized by this process. A significant loss in volume can be seen within a year after the acquisition. After 2-3 years, some batteries fail altogether. But a lot depends on the manufacturer, since within the segment there are also differences in the quality of the battery performance. Similar problems are inherent in NiMH cells, which age under extreme temperature fluctuations.

disadvantages

In addition to problems with rapid aging, such batteries need an additional protection system. This is due to the fact that internal stress in different areas can lead to burnout. Therefore, a special stabilization circuit is used to prevent overheating and overcharging. This system also has other disadvantages. The main one is the current limitation. But on the other hand, additional protective circuits make the lithium polymer battery safer. The difference from the ionic in terms of cost also takes place. Polymer batteries are cheaper, but not much. Their price tag is also increasing due to the introduction of electronic protective circuits.

Operational features of gel modifications

In order to increase the electrical conductivity, the technologists still add a gel-like electrolyte to the polymer elements. There is no talk of a complete transition to such substances, since this contradicts the concept of this technology. But in portable technology, it is often precisely hybrid batteries that are used. Their peculiarity lies in their sensitivity to temperature. Manufacturers recommend using these battery models in environments between 60 ° C and 100 ° C. This requirement also defined a special niche for application. Gel models can only be used in hot climates, not to mention the need to immerse themselves in a thermally insulated case. Nevertheless, the question of which battery to choose - Li-pol or Li-ion - is not so acute in enterprises. Where temperature is particularly influential, combined solutions are often used. In such cases, polymer elements are usually used as backup.

Optimal charging method

Typical replenishment time for lithium batteries is on average 3 hours. Moreover, during charging, the unit remains cold. The filling takes place in two stages. At the first, the voltage reaches its peak values, and this mode is maintained up to 70%. The remaining 30% are recruited already under normal stress conditions. Another question is also interesting - how to charge a lithium-polymer battery if you need to maintain its full volume in a constant mode? In this case, the recharging schedule should be followed. It is recommended to perform this procedure approximately every 500 hours of operation with a complete discharge.

Precautionary measures

During operation, use only a charger that matches the characteristics, connecting it to a network with a stable voltage. It is also necessary to check the condition of the connectors so that the battery does not open. It is important to take into account that, despite the high degree of safety, this is still a type of battery sensitive to overloads. The lithium polymer cell does not tolerate overcurrents, excessive cooling of the external environment and mechanical shock. However, according to all these indicators, polymer blocks are still more reliable than lithium-ion ones. Still, the main aspect of safety is the harmlessness of solid-state power supplies - provided, of course, that they are kept sealed.

Which battery is better - Li-pol or Li-ion?

This issue is largely determined by the operating conditions and the target of the energy supply. The main advantages of polymer devices are rather tangible for the manufacturers themselves, who can more freely use new technologies. The difference will be subtle to the user. For example, in the question of how to charge a lithium polymer battery, the owner will have to pay more attention to the quality of the power supply. By the time of the charge, these are identical elements. As for durability, the situation in this parameter is also ambiguous. The aging effect is more characteristic of polymer elements, but practice shows different examples. For example, there are reviews of lithium-ion cells that become unusable after a year of use. And polymer in some devices are operated for 6-7 years.

Conclusion

Around the batteries, there are still many myths and false judgments that relate to various nuances of operation. Conversely, some of the features of batteries are hushed up by manufacturers. As for the myths, one of them refutes the lithium polymer battery. The difference from the ionic analogue is that polymer models experience less internal stress. For this reason, charging sessions that have not yet run down batteries do not adversely affect the performance of the electrodes. If we talk about the facts hidden by manufacturers, then one of them concerns durability. As already mentioned, the battery life is characterized not only by a modest rate of charging cycles, but also by the inevitable loss of the useful volume of the battery.

Lithium-ion and lithium-polymer batteries

Engineering thought is constantly evolving: it is stimulated by constantly arising problems that require the development of new technologies for their solution. Nickel-cadmium (NiCd) batteries were replaced by nickel-metal hydride (NiMH) batteries, and now they are trying to take the place of lithium-ion (Li-ion) batteries. NiMH batteries have to some extent pushed NiCd out, but due to such indisputable advantages of the latter as the ability to deliver high current, low cost and long service life, they could not provide their full replacement. But what about lithium batteries? What are their features and how do Li-pol batteries differ from Li-ion? Let's try to understand this issue.

As a rule, when buying a mobile phone or laptop, we all do not think about what kind of battery they have inside and how these devices generally differ. And only then, faced in practice with the consumer qualities of certain batteries, we begin to analyze and choose. For those who are in a hurry and want to immediately get an answer to the question of which battery is optimal for a cell phone, I will answer briefly - Li-ion. Further information is intended for the curious.

To begin with, a small excursion into history.

The first experiments to create lithium batteries began in 1912, but only six decades later, in the early 70s, they were first introduced into household devices. Moreover, I emphasize, these were exactly the batteries. Subsequent attempts to develop lithium batteries (rechargeable batteries) have been unsuccessful due to safety concerns. Lithium, the lightest of all metals, has the highest electrochemical potential and provides the highest energy density. Batteries using lithium metal electrodes have both high voltage and excellent capacity. But as a result of numerous studies in the 80s, it was found that the cyclic operation (charge - discharge) of lithium batteries leads to changes on the lithium electrode, as a result of which thermal stability decreases and there is a threat of the thermal state going out of control. When this happens, the temperature of the cell quickly approaches the melting point of lithium - and a violent reaction begins, igniting the evolved gases. For example, a large number of lithium mobile phone batteries shipped to Japan in 1991 were recalled after several incidents of fire.

Due to the inherent instability of lithium, the researchers turned their attention towards non-metallic lithium batteries based on lithium ions. Having lost a little at the same time in energy density and taking some precautions when charging and discharging, they got safer so-called Li-ion batteries.

The energy density of Li-ion batteries is usually twice the density of standard NiCd, and in the future, thanks to the use of new active materials, it is expected to further increase it and achieve a threefold superiority over NiCd. In addition to the large capacity, the Li-ion battery, when discharged, behaves similarly to NiCd (the shape of their discharge characteristics is similar and differs only in voltage).

At the moment, there are many varieties of Li-ion batteries, and you can talk for a long time about the advantages and disadvantages of one type or another, but it is impossible to distinguish them by their appearance. Therefore, we note only those advantages and disadvantages that are inherent in all types of these devices, and consider the reasons that caused the birth of lithium-polymer batteries.

Main advantages.

- High energy density and, as a result, high capacity with the same dimensions compared to nickel-based batteries.

- Low self-discharge.

- High single cell voltage (3.6 V versus 1.2 V for NiCd and NiMH), which simplifies the design - often the battery consists of only one cell. Many manufacturers today use such a single cell battery in cell phones (remember Nokia). However, to provide the same power, a higher current must be delivered. And this requires ensuring a low internal resistance of the element.

- Low maintenance (running) cost is a result of no memory effect requiring periodic discharge cycles to restore capacity.

Disadvantages.

Li-ion battery technology is constantly improving. It is updated approximately every six months, and it is difficult to understand how new batteries behave after long-term storage.

In a word, everyone would have a good Li-ion battery if it were not for the problems with ensuring the safety of its operation and its high cost. Attempts to solve these problems led to the emergence of lithium-polymer (Li-pol or Li-polymer) batteries.

Their main difference from Li-ion is reflected in the name and lies in the type of electrolyte used. Initially, in the 70s, a dry solid polymer electrolyte was used, similar to a plastic film and not conducting electric current, but allowing the exchange of ions (electrically charged atoms or groups of atoms). The polymer electrolyte actually replaces the traditional porous electrolyte impregnated separator.

This design simplifies the manufacturing process, is safer and allows the production of thin, freeform batteries. In addition, the absence of a liquid or gel electrolyte eliminates the possibility of ignition. The thickness of the element is about one millimeter, so that equipment designers are free to choose the shape, shape and size, up to embedding it in clothing fragments.

But so far, unfortunately, dry Li-polymer batteries have insufficient electrical conductivity at room temperature. Their internal resistance is too high and cannot provide the amount of current required for modern communications and power supply of laptop hard drives. At the same time, when heated to 60 ° C or more, the electrical conductivity of the Li-polymer increases to an acceptable level, but this is not suitable for mass use.

Researchers continue to develop dry solid electrolyte Li-polymer batteries that operate at room temperature. Such batteries are expected to be commercially available by 2005. They will be stable, allow 1000 full charge-discharge cycles and have a higher energy density than today's Li-ion batteries.

Meanwhile, some types of Li-polymer batteries are currently used as backup power supplies in hot climates. For example, some manufacturers specifically install heating elements that maintain a temperature favorable for the battery.

You ask: how is that? Li-polymer batteries are being sold on the market with might and main, manufacturers equip phones and computers with them, and here we say that they are not yet ready for commercial use. Everything is very simple. In this case, we are talking about batteries not with a dry solid electrolyte. In order to increase the electrical conductivity of small Li-polymer batteries, some gel electrolyte is added to them. And most of the Li-polymer batteries used for mobile phones today are actually hybrids because they contain a gel-like electrolyte. It would be more correct to call them lithium-ion polymer. But most manufacturers simply label them as Li-polymer for promotional purposes. Let us dwell on this type of lithium polymer batteries in more detail, since at the moment they are of the greatest interest.

So what is the difference between a Li-ion and a Li-polymer battery with a gel electrolyte additive? Although the characteristics and efficiency of both systems are largely similar, the uniqueness of the Li-ion polymer (you can even call it that) battery is that it still uses a solid electrolyte, which replaces a porous separator. Gel electrolyte is added only to increase ionic conductivity.

Technical difficulties and a delay in ramping up production have delayed the introduction of Li-ion polymer batteries. This is due, according to some experts, to the desire of investors who have invested a lot of money in the development and mass production of Li-ion batteries, to get their investments back. Therefore, they are in no hurry to switch to new technologies, although during mass production, Li-ion polymer batteries will be cheaper than lithium-ion batteries.

And now about the features of the operation of Li-ion and Li-polymer batteries.

Their main characteristics are very similar. The charge of Li-ion batteries is described in sufficient detail in the article. In addition, I will give only a graph (Fig. 1) from, illustrating the stages of charging, and small explanations to it.

The charging time of all Li-ion batteries with an initial charging current of 1C (numerically equal to the nominal value of the battery capacity) is on average 3 hours. Full charge is achieved when the battery voltage is equal to the upper threshold, and when the charge current decreases to a level approximately equal to 3% of the initial value. The battery remains cold during charging. As you can see from the graph, the charging process consists of two stages. At the first (a little over an hour), the voltage rises at an almost constant initial charge current of 1C until the first reaching the upper voltage threshold. At this point, the battery is charged to about 70% of its capacity. At the beginning of the second stage, the voltage remains almost constant, and the current decreases until it reaches the above 3%. After that, the charge is completely terminated.

If it is required to keep the battery in a charged state all the time, it is recommended to recharge after 500 hours, or 20 days. Usually it is carried out when the voltage at the terminals of the battery decreases to 4.05 V and stops when it reaches 4.2 V

A few words about the temperature range when charging. Most types of Li-ion batteries can be charged with a current of 1C at a temperature of 5 to 45 ° C. At temperatures from 0 to 5 ° C, it is recommended to charge with a current of 0.1 C. Charging at sub-zero temperatures is prohibited. The optimum temperature for charging is 15 to 25 ° C.

The charging processes in Li-polymer batteries are almost identical to those described above, so there is absolutely no need for the consumer to know which of the two types of batteries he has in his hands. And all those chargers that he used for Li-ion batteries are suitable for Li-polymer.

And now about the discharge conditions. Typically, Li-ion batteries are discharged to 3.0 V per cell, although for some varieties the lower threshold is 2.5 V. Battery powered equipment manufacturers typically design devices with a 3.0 V shutdown threshold (for all occasions). What does this mean? The voltage on the battery when the phone is turned on gradually decreases, and as soon as it reaches 3.0 V, the device will warn you and turn off. However, this does not mean at all that he has stopped consuming energy from the battery. Energy, albeit insignificant, is required to determine when the phone's power key is pressed and some other functions. In addition, energy is consumed by its own internal control and protection circuit, and self-discharge, albeit small, is still typical even for lithium-based batteries. As a result, if you leave lithium batteries for a long time without recharging, the voltage on them will drop below 2.5 V, which is very bad. In this case, it is possible to disable the internal control and protection circuit, and not all chargers will be able to charge such batteries. In addition, deep discharge negatively affects the internal structure of the battery itself. A fully discharged battery should be charged at the first stage with a current of only 0.1C. In a word, batteries rather like to be in a charged state than in a discharged state.

A few words about the temperature conditions during discharge (read during operation).

Generally, Li-ion batteries perform best at room temperature. Working in warmer conditions will seriously shorten their lifespan. Although, for example, a lead-acid battery has the highest capacity at temperatures over 30 ° C, prolonged use in such an environment will shorten the life of the battery. Likewise, Li-ion performs better at high temperatures, which initially counteracts the increase in internal resistance of the battery that results from aging. But the increased energy output is short, because the rise in temperature, in turn, promotes accelerated aging, accompanied by a further increase in internal resistance.

The only exceptions are currently lithium-polymer batteries with dry solid polymer electrolyte. For them, a temperature of 60 ° C to 100 ° C is vital. And such batteries have occupied their niche in the market of backup sources in places with hot climates. They are placed in a heat-insulated case with built-in heating elements powered from an external network. Li-ion polymer batteries as a backup are considered to be superior in capacity and durability to VRLA batteries, especially in the field where temperature control is not possible. But their high price remains a deterrent.

At low temperatures, the efficiency of batteries in all electrochemical systems drops sharply. While for NiMH, SLA and Li-ion batteries, -20 ° C is the limit at which they stop functioning, NiCd continues to operate down to -40 ° C. I will only note that again, we are talking only about batteries of widespread use.

It is important not to forget that although the battery can operate at low temperatures, this does not mean that it can also be charged under these conditions. The charge susceptibility of most batteries at very low temperatures is extremely limited and the charge current in these cases should be reduced to 0.1C.

In conclusion, I would like to note that you can ask questions and discuss problems related to Li-ion, Li-polymer, as well as other types of batteries on the forum in the accessories sub-forum.

When writing the article, materials were used [- Batteries for mobile devices and laptop computers. Battery analyzers.

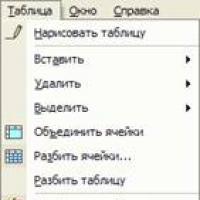

Technical means of data processing

Technical means of data processing Moscow State University of Printing Arts Technical support CAD

Moscow State University of Printing Arts Technical support CAD Moscow State University of Printing Arts

Moscow State University of Printing Arts Manipulation tricks. Logical manipulations. Psychology of influence on people

Manipulation tricks. Logical manipulations. Psychology of influence on people Definition of the terms "Edition", "Electronic publication", "Branded electronic publication Regulatory electronic publication

Definition of the terms "Edition", "Electronic publication", "Branded electronic publication Regulatory electronic publication Introduction to the specialty

Introduction to the specialty Introduction to the specialty

Introduction to the specialty